A kind of preparation method of liquid crystal microcapsule and liquid crystal microcapsule

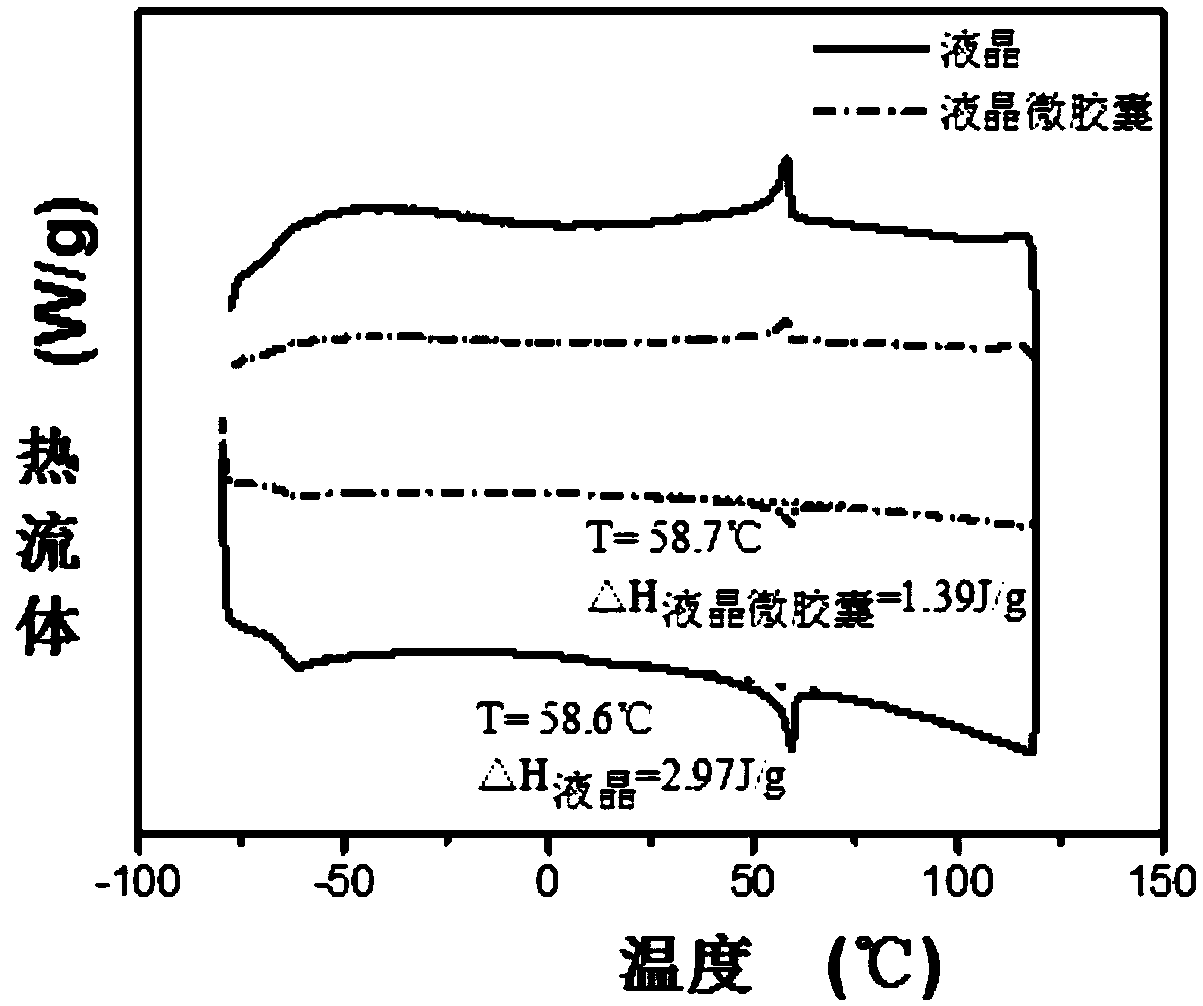

A technology of microcapsules and liquid crystals, applied in the field of composite materials, can solve problems such as poor optical properties of liquid crystal microcapsules, and achieve the effects of easy industrialized production, improved encapsulation rate and coating rate, and high liquid crystal coating rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0082] In this embodiment, epoxy resin-polyethylene glycol copolymer is used as emulsifier.

[0083] 1) 2g of 3.3wt% epoxy resin-polyethylene glycol copolymer aqueous solution is added to 48g water, and the pH value is adjusted to 3.5 with hydrochloric acid, and this solution is used as the water phase;

[0084] 2) Mix 1g of liquid crystal, 0.15g of γ-glycidyl etheroxypropyl trimethoxysilane and 1g of E-51, and ultrasonically disperse them to make them evenly mixed as the oil phase;

[0085] 3) Mix the above-mentioned water phase and oil phase, and use an ultrasonic cell disruptor to ultrasonically emulsify for 2 minutes at a power of 200w to obtain an oil-in-water emulsion;

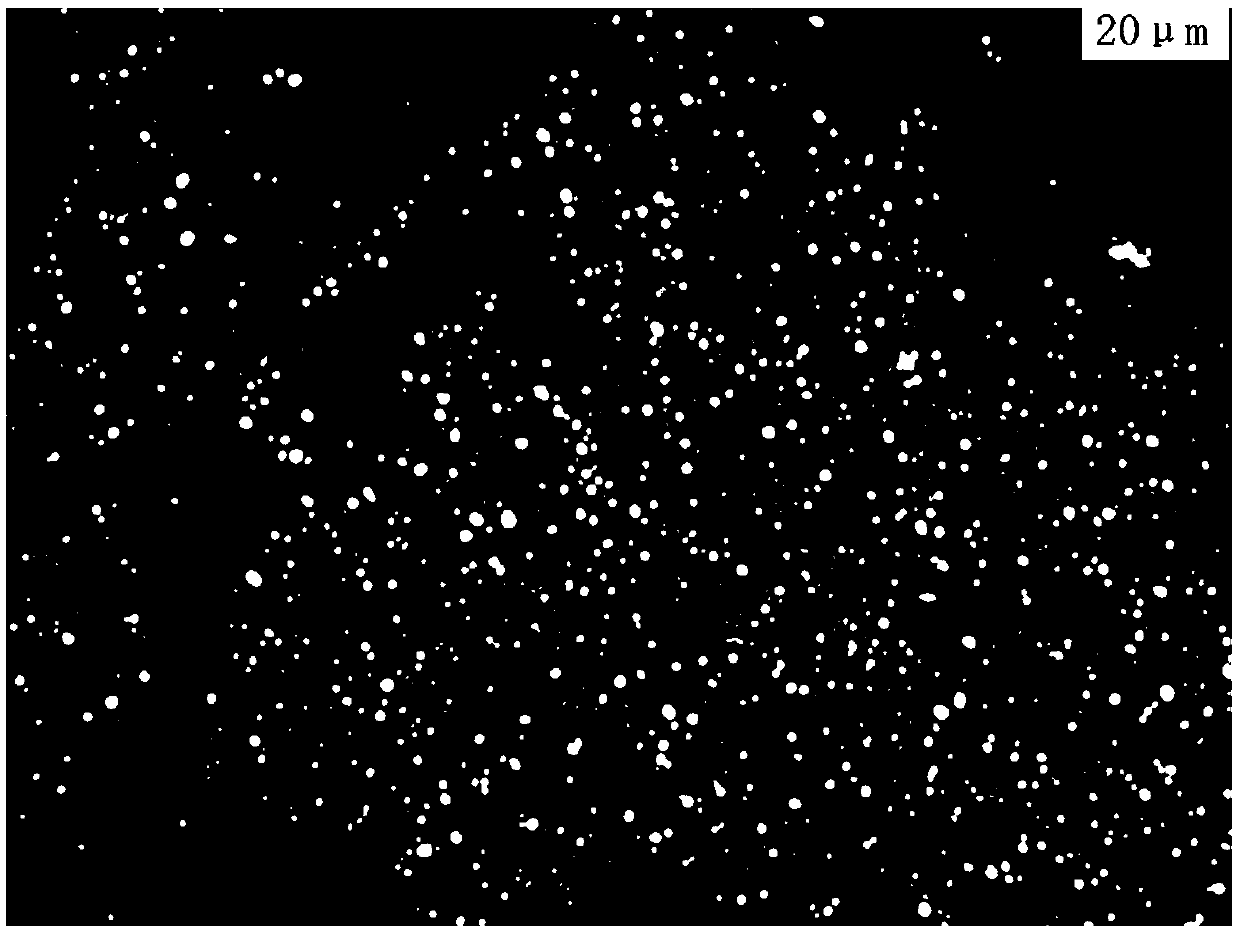

[0086] 4) Transfer the above-mentioned oil-in-water emulsion to a preheated reaction kettle, mechanically stir at 300 rpm, and react at 70°C for about 3 hours. As the polymerization reaction progresses, the silane coupling agent slowly dissolves in the oil-water The interface sol-gel forms the initial s...

Embodiment 2

[0091] In this example, sodium salt hydrolyzate of alternating copolymer of styrene and maleic anhydride (purchased from Sartomer) was used as an emulsifier.

[0092] 1) Add 3 g of sodium salt of 10 wt % styrene-maleic anhydride alternating copolymer to 47 g of water, adjust the pH value to 9 with ammonia water, and use this solution as the water phase;

[0093] 2) Mix 2g of liquid crystal, 0.25g of γ-glycidyl etheroxypropyltrimethoxysilane and 1.5g of E-51, and ultrasonically disperse them to make them evenly mixed as the oil phase;

[0094] 3) the above-mentioned water phase and oil phase are mixed, and a microporous membrane with an average pore diameter of 55 nm is used for membrane emulsification to obtain an oil-in-water emulsion;

[0095] 4) Transfer the above-mentioned oil-in-water emulsion to a preheated reaction kettle, introduce inert gas-nitrogen, mechanically stir at 300 rpm, and react at 70°C for about 3 hours. As the polymerization reaction proceeds, The silane...

Embodiment 3

[0101] In this embodiment, epoxy resin-polyethylene glycol copolymer is used as emulsifier.

[0102] 1) 2.5 g of 3.3 wt % epoxy resin-polyethylene glycol copolymer aqueous solution is added to 47.5 g of water, and the pH value is adjusted to 4.7 with hydrochloric acid, and this solution is used as the water phase;

[0103] 2) Mix 1g of liquid crystal, 0.1g of γ-aminopropyltriethoxysilane and 0.3g of E-51, and ultrasonically disperse them to make them evenly mixed as the oil phase;

[0104]3) Mix the above-mentioned water phase and oil phase, and use an ultrasonic cell disruptor to ultrasonically emulsify for 2 minutes at a power of 300w to obtain an oil-in-water emulsion;

[0105] 4) Transfer the above-mentioned oil-in-water emulsion to a preheated reaction kettle, introduce inert gas-nitrogen, mechanically stir at 300 rpm, and react at 70°C for about 6 hours. As the polymerization reaction proceeds, The silane coupling agent slowly forms the initial shell at the oil-water in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com