Cooking utensil with two walls

一种烹饪装置、盛装的技术,应用在烹饪器皿特殊材料、烹调器皿、家里用具等方向,能够解决PTFE涂层耐磨损性有限等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

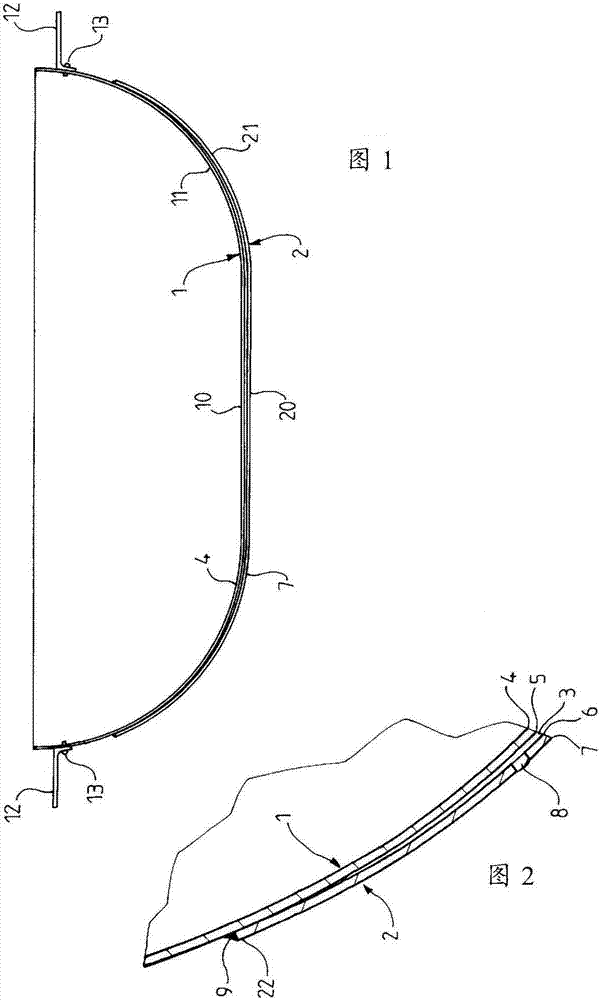

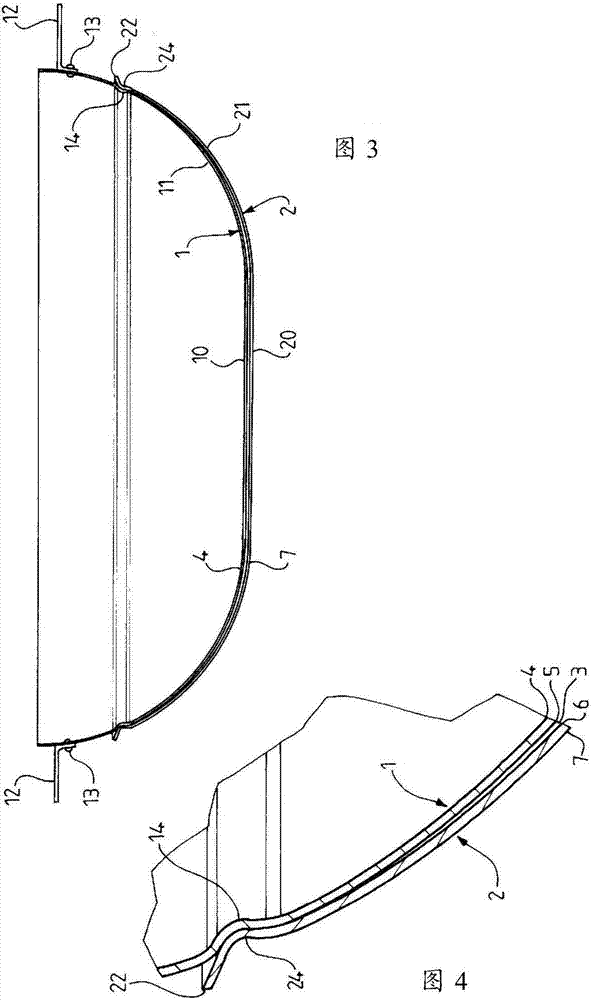

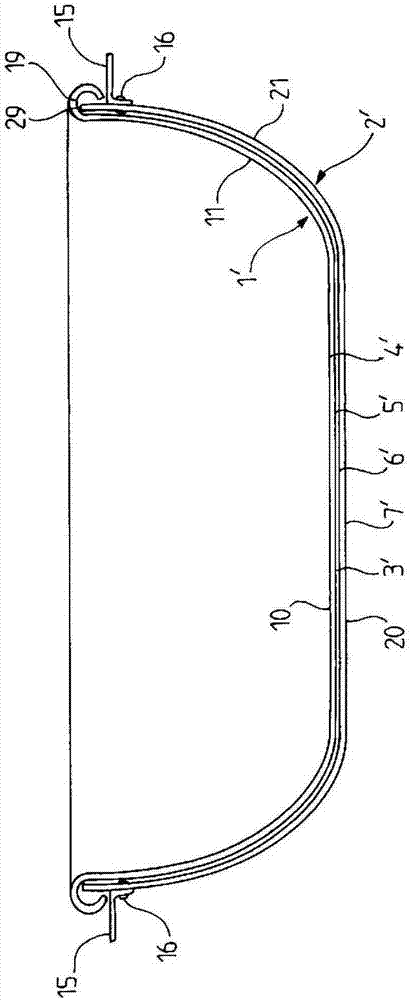

[0035] Figure 1 to Figure 6 The illustrated embodiment relates to a cooking device with double walls, comprising: an inner wall 1, 1' for containing the food to be cooked, and an outer wall 2, 2' for being heated, wherein the air gap 3 , 3' are arranged between the inner wall 1, 1' and the outer wall 2, 2'.

[0036] The inner wall 1, 1' has a cooking inner face 4, 4' and an outer face 5, 5' at least partly sheathed by the outer wall 2, 2'. The thickness of the inner wall 1, 1' is preferably less than 1.6mm and preferably between 0.4mm and 1.2mm. The material of the inner wall 1, 1' is selected from carbon steel (aciers ordinaires). The material of the inner wall 1, 1' is preferably chosen from steel with good stamping properties. In particular, the material of the inner wall 1, 1' can be chosen from carbon low carbon steel, such as DC04. The material of the inner wall 1, 1' can be selected from alloy steel with slightly higher corrosion resistance, so it will not ent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com