Waterproof gas permeable layer for metal fuel cells and preparation method thereof

A metal fuel cell, waterproof and breathable layer technology, applied in applications, household appliances, ceramic products, etc., can solve the problems of complex preparation process of waterproof and breathable layer, high production cost, difficult to control, etc., to achieve good industrial application prospects, thermal stability. The effect of strong performance and good chemical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

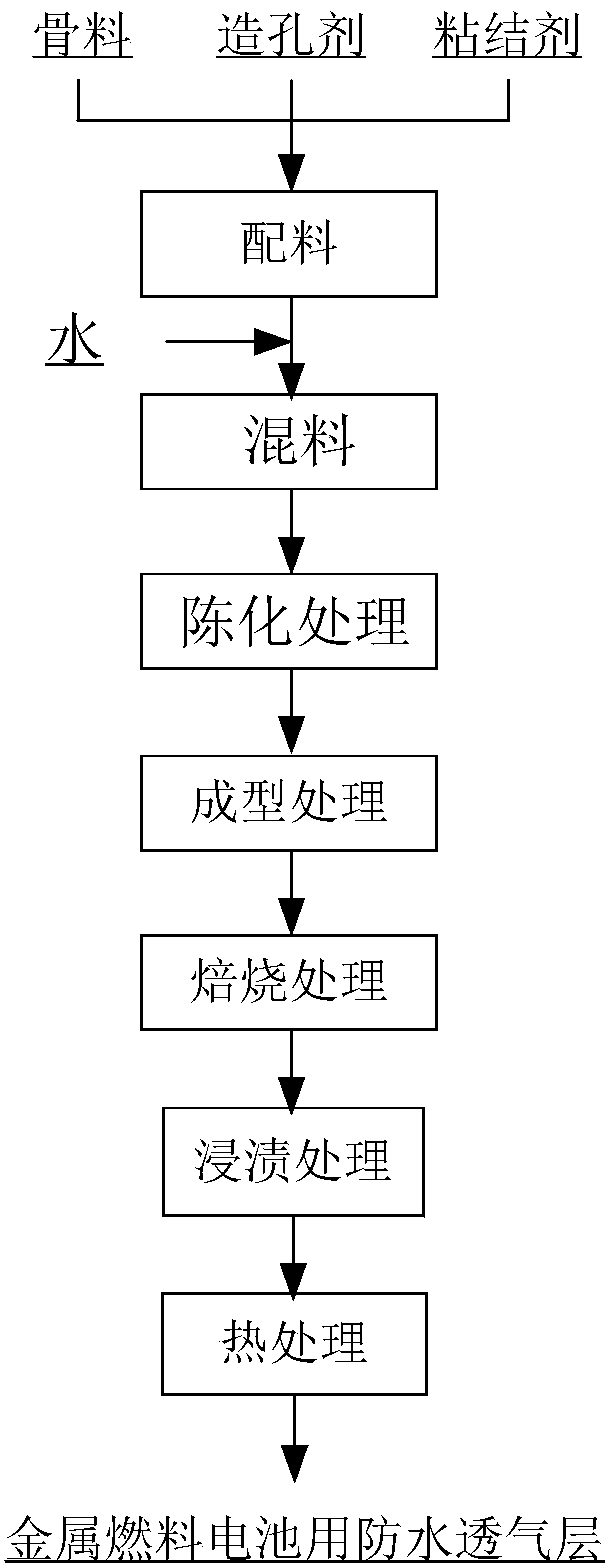

[0024] The method for preparing a waterproof and gas-permeable layer for metal fuel cells in the above embodiments of the present invention uses functional ceramic materials as aggregates, and adds pore-forming agents and binders for wet mixing, aging, and molding to obtain green bodies, and further The green body is subjected to roasting treatment, impregnation treatment and heat treatment to obtain the waterproof and air-permeable layer for the metal fuel cell. The waterproof and gas-permeable layer for the metal fuel cell prepared by the method has good chemical stability, mechanical resistance and thermal stability, and has good industrial application prospects.

[0025] Refer below figure 1 The method for preparing the waterproof and gas-permeable layer for metal fuel cells embodied in the present invention is described in detail.

[0026] Ingredients mix

[0027] According to a specific embodiment of the present invention, aggregate, pore forming agent, binder and wate...

Embodiment

[0054] (1) A preparation method of a metal fuel cell waterproof breathable layer, microporous ceramic preparation: take ZrO, Al 2 o 3 , ZnO, SiO 2 Mix the aggregates with a mass ratio of 3:1:0.5:0.5, and add the pore-forming agent starch and CaCO with a mass ratio of 1:1. 3 , a binder with a mass ratio of 2:1 CMC:AlPO 4 Stir in a high-speed mixer for 10 hours; then add distilled water and stir in a high-speed mixer for 5 hours; place the wet mixture at 25 for 6 hours, dry it in a drying oven at 60°C for 10 hours, and grind it mechanically for 15 hours; hold the pressure for 6 minutes under a pressure of 50 MPa to obtain Green body; finally, the green body is sintered in an air atmosphere at a heating rate of 10°C / min to 1750°C for 10 hours at normal pressure, and at a cooling rate of 40°C / min to room temperature to obtain microporous ceramics.

[0055] (2) Microporous ceramic surface treatment:

[0056] The microporous ceramics were treated in 20% organic solution of polyd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com