Low-temperature H2S gas-sensitive material and preparation method

A low-temperature vulcanization and hydrogen technology, applied in the field of electrochemistry, can solve difficult problems such as realization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

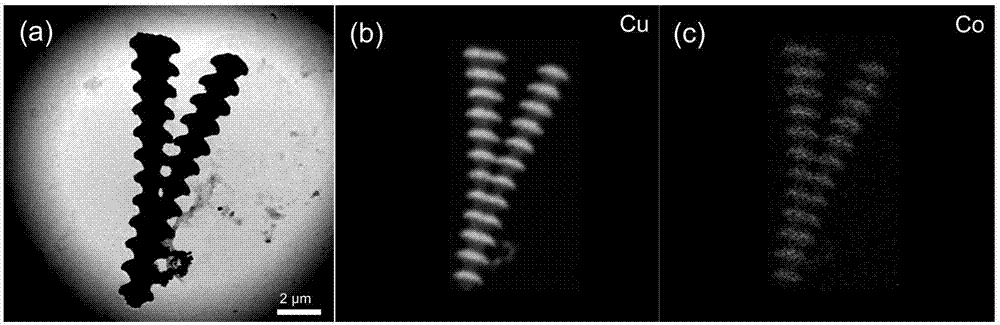

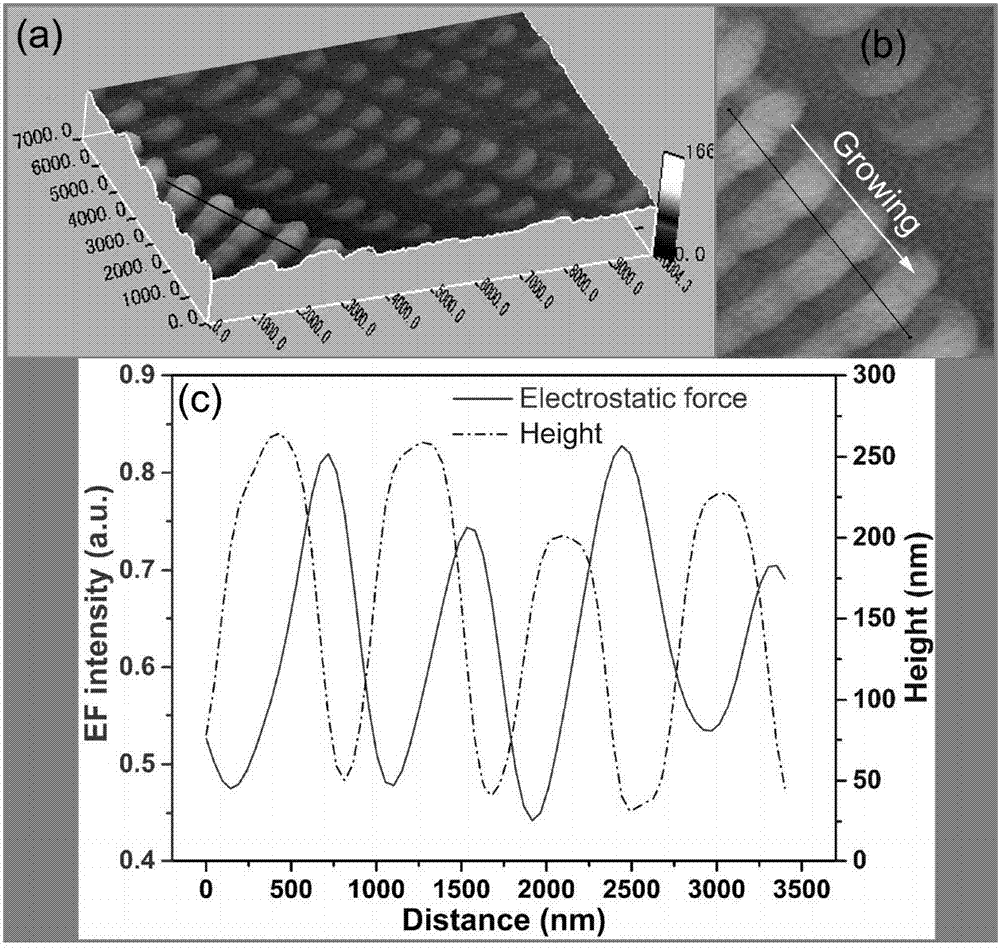

[0034] The low-temperature hydrogen sulfide gas sensitive material is composed of continuously distributed Cu 2 O and periodically spaced Co 3 o 4 constituted and is based on Cu 2 O and Cu 2 O-Co 3 o 4 Lateral Periodic Heterostructure Ordered Array Materials of Composite Materials.

[0035] Its preparation method comprises the following steps:

[0036] (1) Using 50mL deionized water and 0.7248g Cu(NO 3 ) 2 and 0.4365g Co(NO 3 ) 2 The electrolyte raw material is used to configure the electrolyte, and the electrolyte uses HNO 3 Adjust the pH to 4;

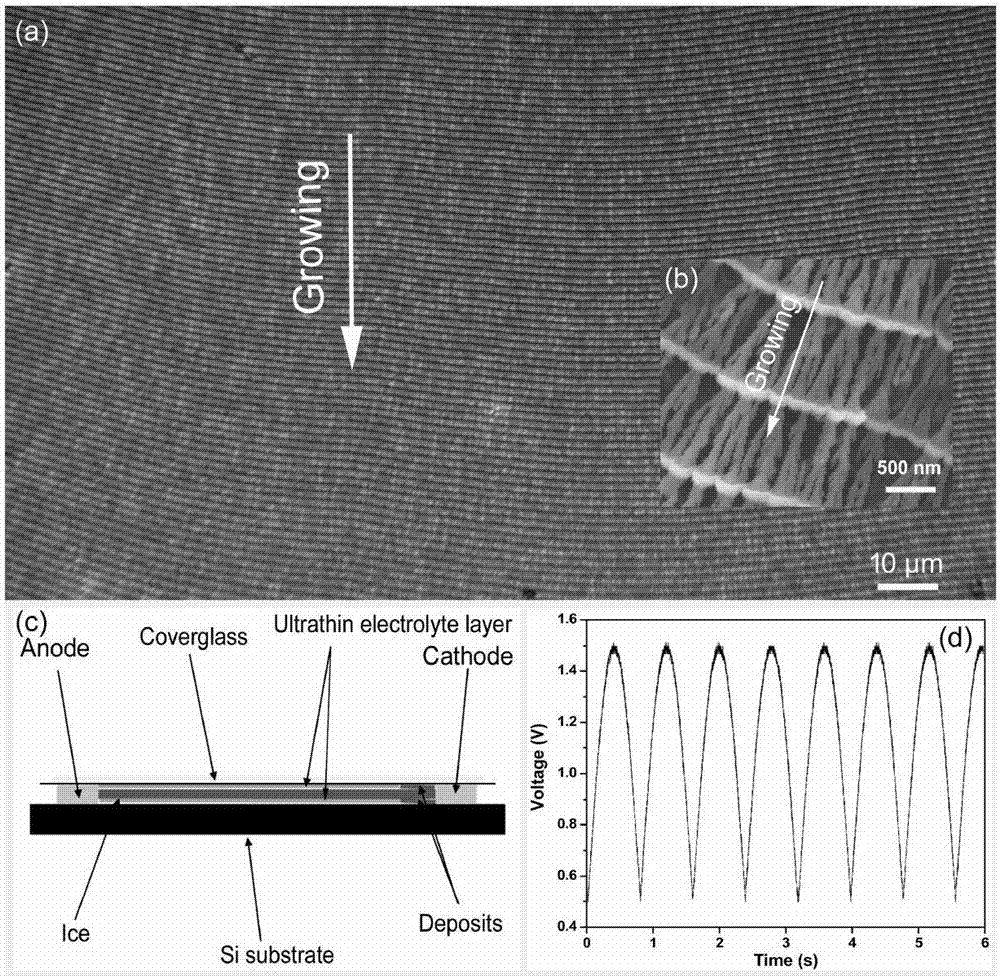

[0037] (2) In the temperature-controlled growth chamber, two 2 mm wide and 3 cm long copper foil electrodes (30 μm thick) are placed parallel to each other at a distance of 6 mm with a surface oxidized silicon wafer or glass wafer as the substrate. On the substrate, drop 20 μL of electrolyte solution between the two electrodes, cover with a cover glass, and control the temperature at -4.5 °C;

[0038] (3) Then use the co...

Embodiment 2

[0048] The low-temperature hydrogen sulfide gas sensitive material is composed of continuously distributed Cu 2 O and periodically spaced Co 3 o 4 constituted and is based on Cu 2 O and Cu 2 O-Co 3 o 4 Lateral Periodic Heterostructure Ordered Array Materials of Composite Materials.

[0049] Its preparation method comprises the following steps:

[0050] (1) Using 20mL deionized water and 0.2899g Cu(NO 3 ) 2 and 0.1746g Co(NO 3 ) 2 The electrolyte raw material is used to configure the electrolyte, and the electrolyte uses HNO 3 Adjust the pH to 3.5;

[0051] (2) In the temperature-controlled growth chamber, two 2 mm wide and 3 cm long copper foil electrodes (30 μm thick) are placed parallel to each other at a distance of 6 mm with a surface oxidized silicon wafer or glass wafer as the substrate. On the substrate, drop 20 μL of electrolyte solution between the two electrodes, cover with a cover glass, and control the temperature at -4.5 °C;

[0052] (3) Then use the ...

Embodiment 3

[0056] The low-temperature hydrogen sulfide gas sensitive material is composed of continuously distributed Cu 2 O and periodically spaced Co 3 o 4 constituted and is based on Cu 2 O and Cu 2 O-Co 3 o 4 Lateral Periodic Heterostructure Ordered Array Materials of Composite Materials.

[0057] Its preparation method comprises the following steps:

[0058] (1) Using 40mL deionized water and 0.5798g Cu(NO 3 ) 2 and 0.3492g Co(NO 3 ) 2 The electrolyte raw material is used to configure the electrolyte, and the electrolyte uses HNO 3 Adjust the pH to 4.5;

[0059] (2) In the temperature-controlled growth chamber, two 2 mm wide and 3 cm long copper foil electrodes (30 μm thick) are placed parallel to each other at a distance of 6 mm with a surface oxidized silicon wafer or glass wafer as the substrate. On the substrate, drop 20 μL of electrolyte solution between the two electrodes, cover with a cover glass, and control the temperature at -4.5 °C;

[0060] (3) Then use the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com