Graphene/nylon 6 textile with permanent anti-ultraviolet function and preparation method thereof

A technology of graphene and nylon, which is applied in melt spinning, rayon manufacturing, textiles and paper making, etc. It can solve the problems of lower cost performance, limited service life, shedding of masking agents, etc., and achieve good product stability and excellent comprehensive performance , good compatibility effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

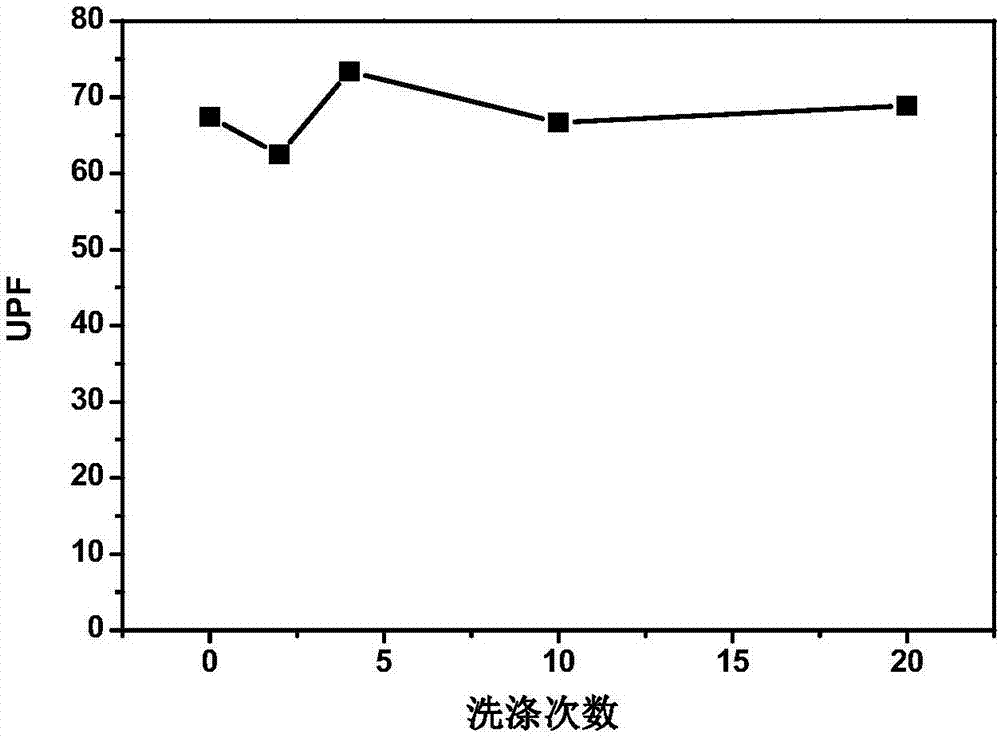

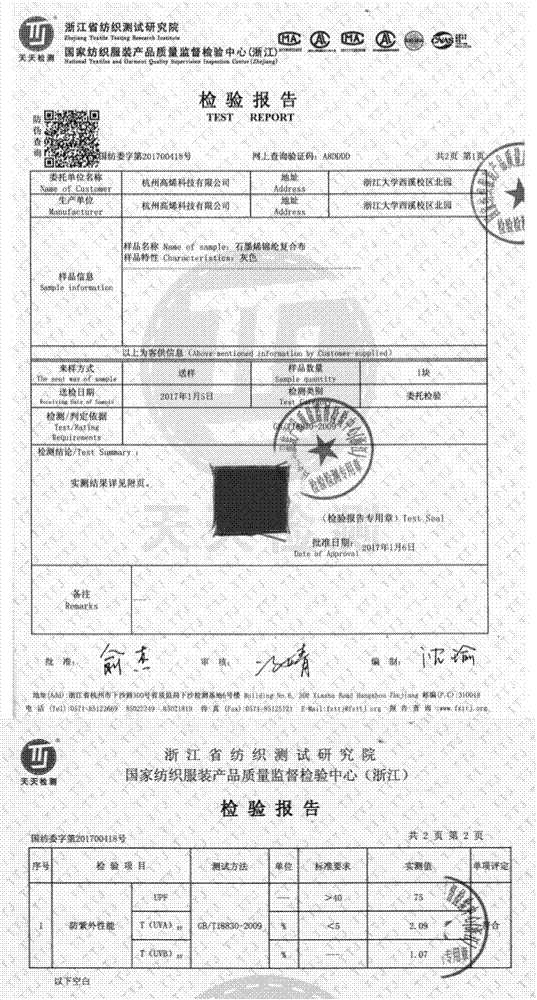

[0023] Add 0.1 parts by mass of single-layer graphene with a carbon-to-oxygen ratio of 3.2 and a lateral size of 2 μm and 10 parts by mass of deionized water into 100 parts by mass of caprolactam melt, and stir and mix at a high speed (400 rpm) at 80°C to form Dispersion liquid; under the protection of nitrogen, the above dispersion liquid was heated to 250°C in a polycondensation reactor, reacted at 0.7Mpa for 3 hours, and then reacted under vacuum for 4 hours to obtain a polycondensate melt; Water-cooled granulation to obtain graphene / nylon 6 nanocomposites. The obtained graphene / nylon 6 nanocomposite material is uniformly dispersed with 0.5 parts of antioxidant at 295° C., the spinning speed is 1000 m / min, and the drafting ratio is 3 times for high-speed melt spinning to obtain graphene / nylon 6 fiber. Fabricate the obtained graphene / nylon 6 fibers, and use 208g of graphene / nylon 6 fibers per square meter. The resulting fabrics are tested according to GB / T18830-2009, and th...

Embodiment 2

[0026] Add 0.2 parts by mass of single-layer graphene with a carbon-to-oxygen ratio of 5.1 and a lateral size of 7 μm and 10 parts by mass of deionized water into 100 parts by mass of caprolactam melt, and stir and mix at a high speed (400 rpm) at 80°C to form Dispersion liquid; under the protection of nitrogen, the above dispersion liquid was heated to 250°C in a polycondensation reactor, reacted at 0.7Mpa for 3 hours, and then reacted under vacuum for 4 hours to obtain a polycondensate melt; Water-cooled granulation to obtain graphene / nylon 6 nanocomposites. The obtained graphene / nylon 6 nanocomposite material is uniformly dispersed with 0.5 parts of antioxidant at 295° C., the spinning speed is 1000 m / min, and the drafting ratio is 3 times for high-speed melt spinning to obtain graphene / nylon 6 fiber. Fabricate the obtained graphene / nylon 6 fibers, and use 180g of graphene / nylon 6 fibers per square meter. The resulting fabric is tested according to GB / T18830-2009, and the ...

Embodiment 3

[0028] Add 0.3 parts by mass of single-layer graphene with a carbon-to-oxygen ratio of 3.2 and a lateral size of 5 μm and 10 parts by mass of deionized water into 100 parts by mass of caprolactam melt, and stir and mix at a high speed (400 rpm) at 80°C to form Dispersion liquid; under the protection of nitrogen, the above dispersion liquid was heated to 250°C in a polycondensation reactor, reacted at 0.7Mpa for 3 hours, and then reacted under vacuum for 4 hours to obtain a polycondensate melt; Water-cooled granulation to obtain graphene / nylon 6 nanocomposites. The obtained graphene / nylon 6 nanocomposite material is uniformly dispersed with 0.5 parts of various additives at 295°C, the spinning speed is 1000 m / min, and the draw ratio is 3 times the condition of high-speed melt spinning to obtain graphene / nylon 6 nanocomposites. Nylon 6 fiber. Fabricate the obtained graphene / nylon 6 fibers, and use 150g of graphene / nylon 6 fibers per square meter. The resulting fabrics are teste...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com