A device and process for removing residual stress of submerged arc tube welds by double-sided flame heating method

A technology of flame heating and residual stress, which is applied to the improvement of process efficiency, heat treatment furnace, manufacturing tools, etc. It can solve the problems of inability to adapt to submerged arc welded pipes of different specifications, adjustment of heating position and heating temperature, etc., to achieve the removal of residual stress Effects of stress and tissue instability, reduction of temperature difference, and removal of residual stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

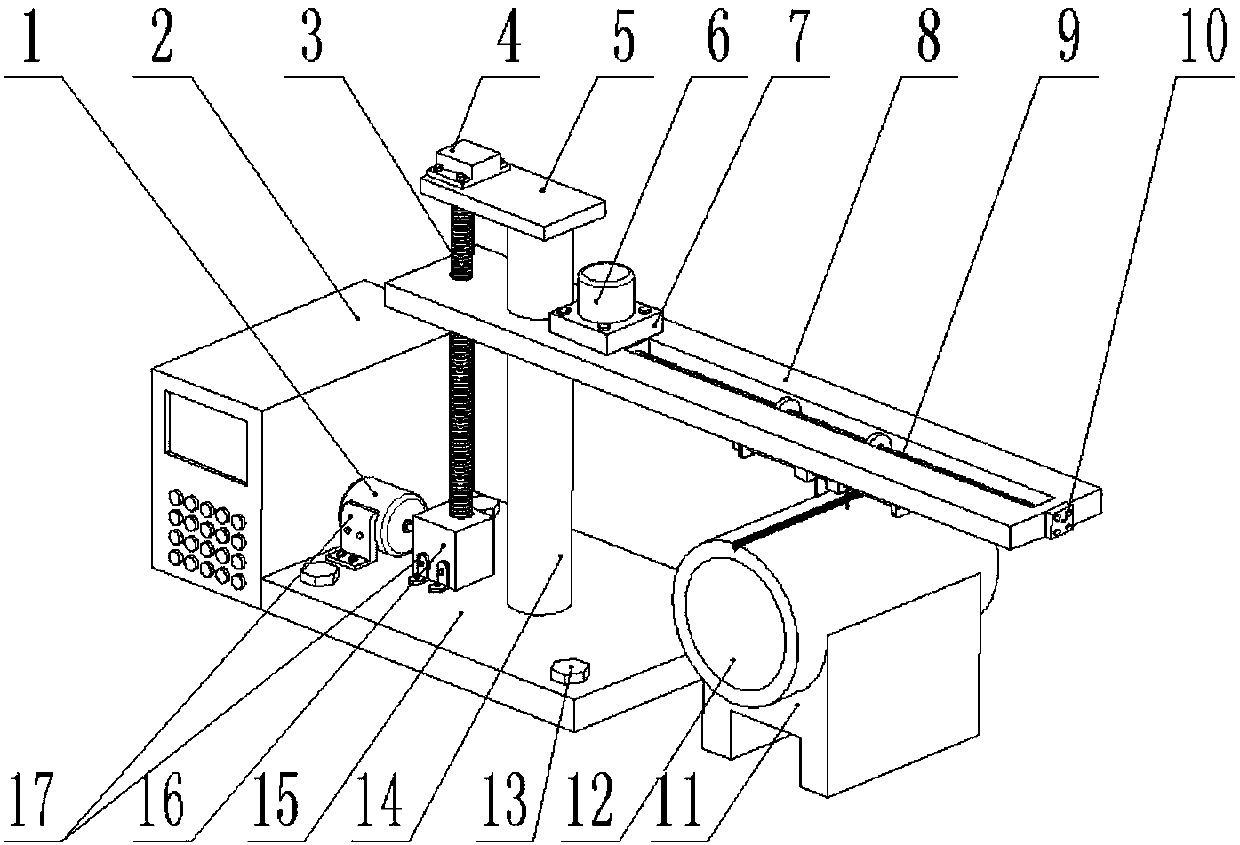

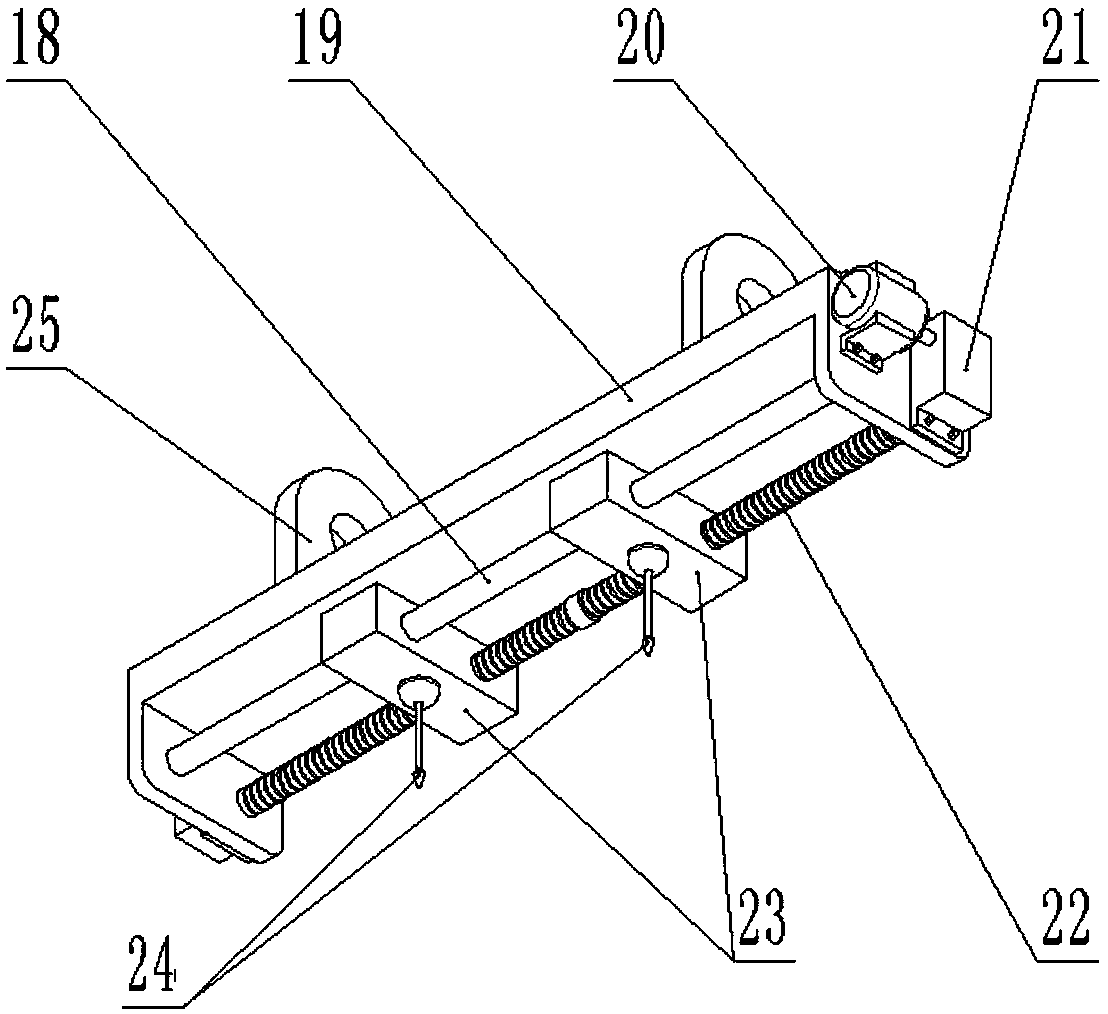

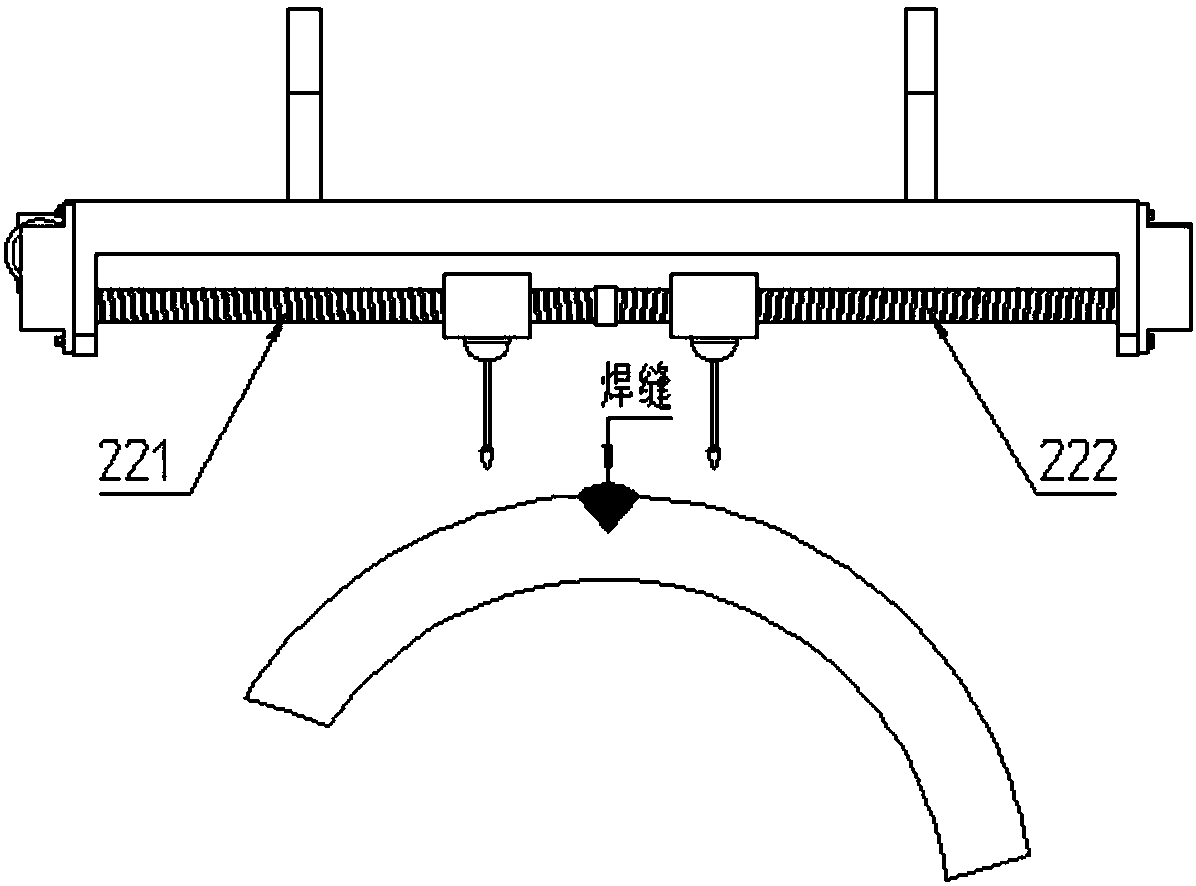

[0023] Such as Figure 1-2 As shown, the device for removing the residual stress of the submerged arc tube welding seam by the bilateral flame heating method in this embodiment includes a numerical control console 2, a vertical transmission mechanism of the lifting plate, a horizontal transmission mechanism of the hanging connecting plate, and a symmetrical transmission mechanism of two sliders , two flame spray guns 24, submerged arc tube 12, submerged arc tube conveying seat 11, base 15, the numerical control console 2 is installed on the left side of the base 15, and the submerged arc tube conveying seat 11 is horizontally placed on the ground; the lifting plate is vertically driven The mechanism includes motor A1, ball screw A3, ball screw support 16, positioning pillar 14, lifting plate 8, motor A is installed on the base 15 through the fixing plate B17,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com