Tarpaulin with high strength as well as preparation method and application thereof

A production method and high-strength technology, applied in chemical instruments and methods, layered products, coatings, etc., can solve problems such as poor flame retardancy, substandard warp and weft breaking tension and elongation, and large weight, and achieve the best flame retardancy Sexuality and anti-aging, beneficial to industrial applications, and beneficial to environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0053] The preparation method of the above resin material comprises the following steps: uniformly mixing 80-88 parts of thermoplastic resin, 6-10 parts of antioxidant, 3-5 parts of anti-ultraviolet light stabilizer and 3-5 parts of flame retardant to obtain the resin material.

[0054] [core layer]

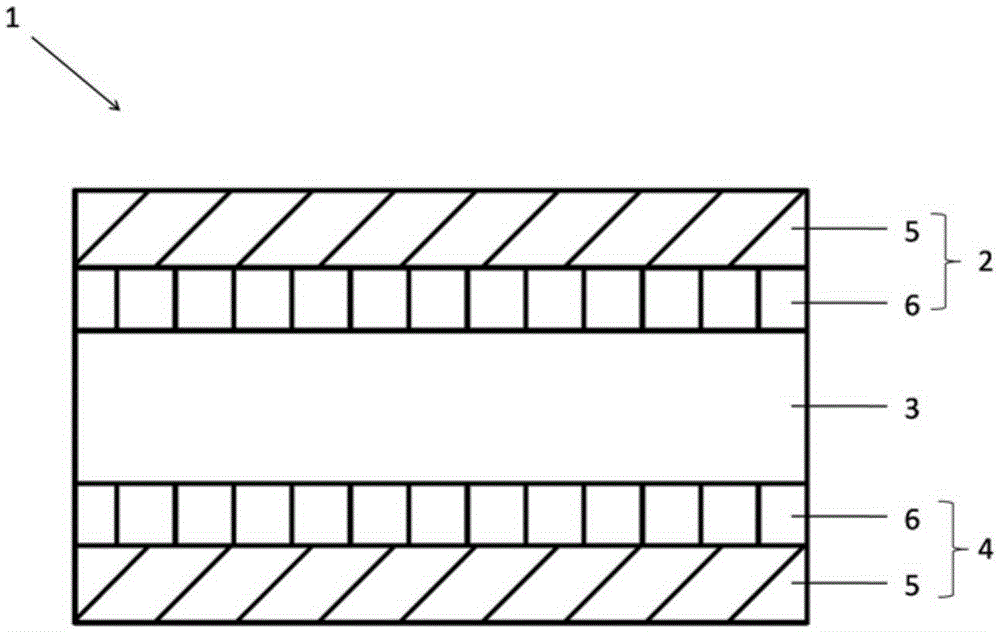

[0055] The thickness of the core layer 3 can be 0.36-0.90mm, preferably 0.5-0.6mm, and it can be made of fiber-reinforced thermoplastic resin prepreg, and the fiber-reinforced thermoplastic resin prepreg is made of more than two fiber-reinforced thermoplastic resin prepregs The belt is laid layer by layer according to the laying method of 0° and 90°.

[0056] The fiber-reinforced thermoplastic resin prepreg tape may include the following components and the parts by weight of each component may be as follows:

[0057] 45-50 parts of continuous fiber;

[0058] 50-55 parts of thermoplastic resin.

[0059] Wherein, the continuous fiber can be selected from any one or more of inorg...

Embodiment 1

[0082] Embodiment one (polypropylene tarpaulin)

[0083] This embodiment provides a polypropylene tarpaulin, which includes a surface layer, a core layer and a bottom layer arranged sequentially from top to bottom.

[0084] Wherein, both the surface layer and the bottom layer are made of resin-coated non-woven fabric on one side, and the thickness thereof is 0.2 mm. The grammage of the resin-coated non-woven fabric on one side is 180g / m 2 .

[0085] Both the surface layer and the bottom layer include a resin sublayer and a nonwoven fabric sublayer, and the weight ratio of the resin sublayer to the nonwoven fabric sublayer is 2:1.

[0086] The resin sublayer is made of a resin material, and the resin material includes the following components and the parts by weight of each component are as follows:

[0087]

[0088] Among them, the antioxidant is 2,6-tertiary butyl-4-methylphenol, the anti-ultraviolet light stabilizer is phenyl hydroxybenzoate, and the flame retardant is...

Embodiment 4

[0133] Embodiment four (polypropylene tarpaulin)

[0134] This embodiment provides a polypropylene tarpaulin, which includes a surface layer, a core layer and a bottom layer arranged sequentially from top to bottom.

[0135] Wherein, both the surface layer and the bottom layer are made of single-side coated resin non-woven fabric, and the thickness thereof is 0.26 mm. The grammage of the resin-coated non-woven fabric on one side is 200g / m 2 .

[0136] Both the surface layer and the bottom layer include a resin sublayer and a nonwoven fabric sublayer, and the weight ratio of the resin sublayer to the nonwoven fabric sublayer is 1.8:1.

[0137] The resin sublayer is made of a resin material, and the resin material includes the following components and the parts by weight of each component are as follows:

[0138]

[0139] Among them, the antioxidant is tetrakis(β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate) pentaerythritol ester, and the anti-ultraviolet light stabilize...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Basis weight | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com