Hydroquinone hydrogenation catalyst, preparation method and hydrogenation reaction method

A technology of hydrogenation catalyst and hydroquinone, which is applied in the direction of hydrogenation preparation, molecular sieve catalyst, chemical instruments and methods, etc., can solve the problem of low yield of 1,4-cyclohexanediol, high requirements for reaction equipment, iodination Eliminate the problems of expensive shirts and other problems, and achieve the effects of simple preparation method, good catalytic effect, and low industrial cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

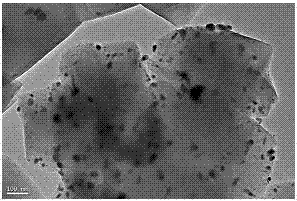

Image

Examples

preparation example Construction

[0021] The preparation method of hydroquinone hydrogenation catalyst, its step is:

[0022] (1) The carrier is pre-calcined in a muffle furnace at 300-600°C for 6 hours, and then sieved for use;

[0023] (2) Prepare a solution with a concentration of 0.3-3.0 mol / L of the soluble compound of the active component Ru with distilled water, add a carrier to the prepared solution, and immerse under strong stirring for 1-5 h to obtain a solution;

[0024] (3) Make the soluble salt of component B of the additive into b solution with a concentration of 0.03~1.0 mol / L;

[0025] (4) Add the prepared b solution directly to a solution to obtain a c mixed solution, and continue aging for 2~10 h after adding;

[0026] (5) The precipitant is made into a d solution with a concentration of 0.03~2.0 mol / L;

[0027] (6) Add the prepared d solution to the c mixed solution dropwise, the reaction temperature is kept at 80 ℃ during the dropping process, and continue to age for 5~20 h after the addi...

Embodiment 1

[0051] Example 1: Weigh 0.3 g of ruthenium chloride hexahydrate and dissolve it in 60 ml of distilled water. After it is completely dissolved, add 5.5 g of HY molecular sieve and soak it at 80°C for 3 h, then dissolve 0.03 g of lanthanum oxide in 20 ml of distilled water Add the above mixed solution and continue stirring and impregnating for 3 h, then add dropwise 0.05 mol / L urea aqueous solution, continue aging for 18 h, filter and wash, then dry at 110 °C for 24 h, grind the dried catalyst to 200 mesh, The obtained catalyst was reductively activated under the following conditions: reduction with hydrogen (hydrogen pressure 0.1-3.0 MPa) at 500 °C for 3 h, and then lowered to room temperature under the protection of high-purity nitrogen. The obtained catalyst sample was recorded as 1# catalyst, and 0.5 g of catalyst 1# was taken for activity evaluation.

Embodiment 2

[0052] Example 2: Weigh 0.3 g of ruthenium oxide and dissolve it in 60 ml of distilled water. After it is completely dissolved, add 5.5 g of NaY molecular sieve and soak it at 80°C for 1.5 h, then dissolve 0.03 g of calcium nitrate in 20 ml of distilled water, add Continue to stir and impregnate in the above mixed solution for 9 h, then add dropwise 0.03 mol / L potassium carbonate aqueous solution, continue aging for 14 h, filter and wash, then dry at 95 °C for 10 h, and then dry at 110 °C for 14 h, The dried catalyst was ground to 200 mesh, and the obtained catalyst was reductively activated under the following conditions: reducing with hydrogen (hydrogen pressure 0.1-3.0 MPa) at 480 °C for 4 h, and then cooling down to room temperature under the protection of high-purity nitrogen. The obtained catalyst sample was recorded as 2# catalyst, and 0.5 g of catalyst 2# was taken for activity evaluation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com