Fast microwave purging method for pipeline system

A pipeline system and microwave technology, applied in the direction of lighting and heating equipment, drying, furnace type, etc., can solve the problem of reducing water vaporization capacity, achieve the effect of improving drying depth, convenient operation, and shortening purge time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

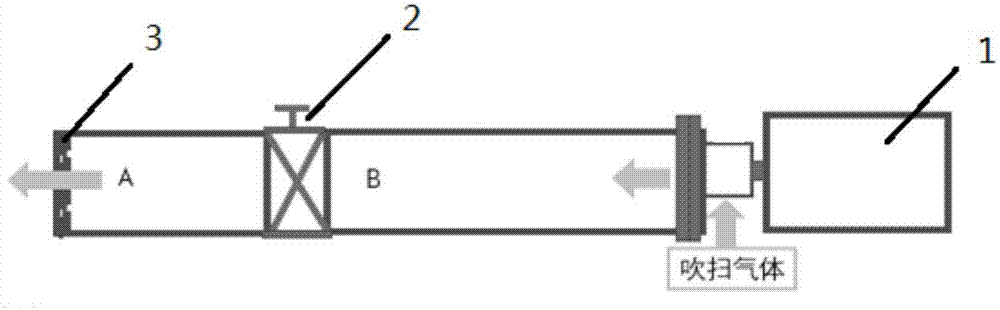

Embodiment 1

[0045] Such as Figure 4 As shown, 4 carbon steel seamless pipes with an outer diameter of 108 mm and a wall thickness of 4 mm (inner diameter of 100 mm) were selected, each 6 meters long, connected together by flanges, a total of 24 meters, and the inner wall of the pipe has oxidation marks. The inner wall that has been placed in a humid outdoor environment for a certain period of time and is not completely dry. Blow with dry air, feed 1000 watts of 2450MHz microwave at the same time, install an online water analyzer at the gas outlet to measure the dew point of the outlet gas, and the blowing flow rate is 1 cubic meter per minute. The measuring range of the water analyzer is dew point -110 degrees Celsius.

[0046] Experimental steps and results:

[0047] Step 1: After continuously feeding dry air for 10 minutes, measure the dew point temperature of the outlet air at -15 degrees Celsius, and stabilize within one minute.

[0048] Step 2: Turn on the microwave power supply ...

experiment example 2

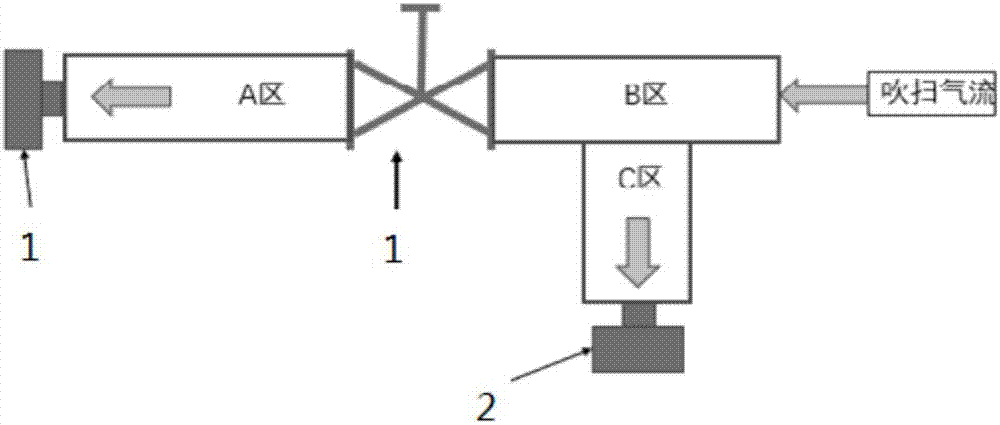

[0051] Choose 3 carbon steel seamless steel pipes with an outer diameter of 168.3 mm and a wall thickness of 7.1 mm, each of which is 9 meters long, and two elbows are added in the middle to form a U-shaped pipe.

[0052] The first step is to discharge the pipe after filling it with water, and blow it with compressed air. When no water vapor can be seen at the outlet, start to connect a water analyzer with a dew point of -110 degrees Celsius, and use dry air instead. For purging, the blowing air flow rate is 1 cubic meter per minute, and the dew point has been reduced from 15 degrees to -30 degrees for 87 minutes.

[0053] In the second step, fill the pipe with water and discharge it, and blow it with compressed air. When no water vapor can be seen at the outlet, start to connect a water analyzer with a range of dew point -110 degrees Celsius, and use the same equipment The treated dry air is purged, the blowing air flow rate is also 1 cubic meter per minute, and 1000 watts of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com