Device system and method for achieving carbon dioxide cyclic power generation through geothermal energy

A cycle power generation, carbon dioxide technology, applied in geothermal energy systems, geothermal energy power generation, mechanical equipment, etc., can solve the problems of large system investment, unsuitable cycle power generation technology and equipment, environmental hazards, etc., to achieve the effect of application safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

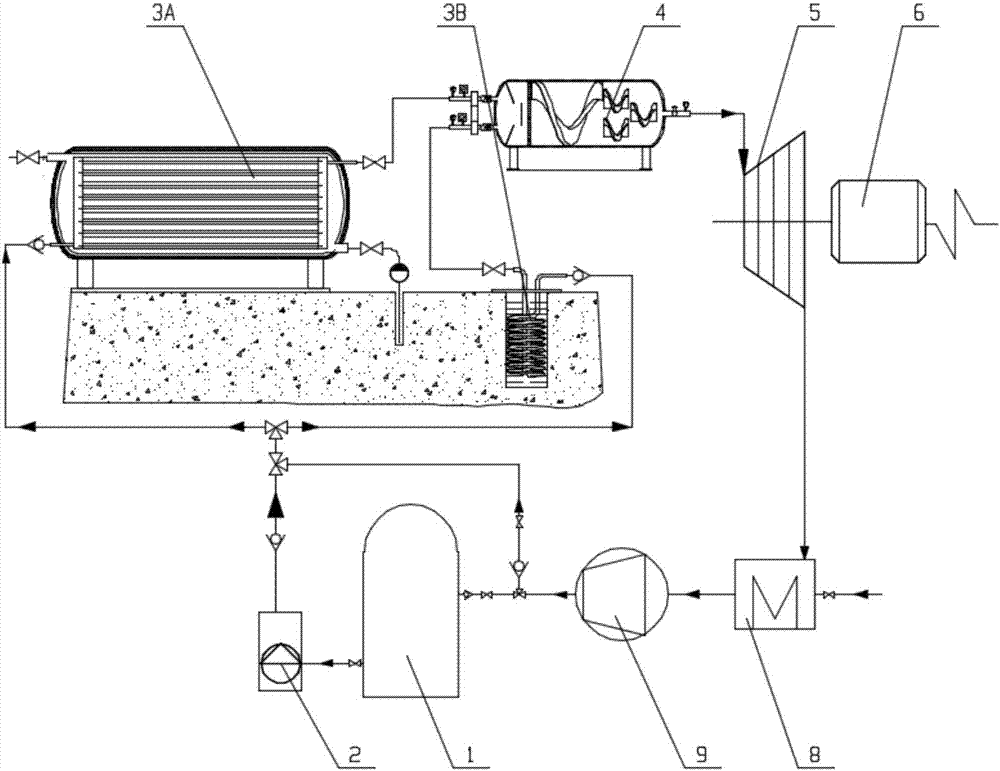

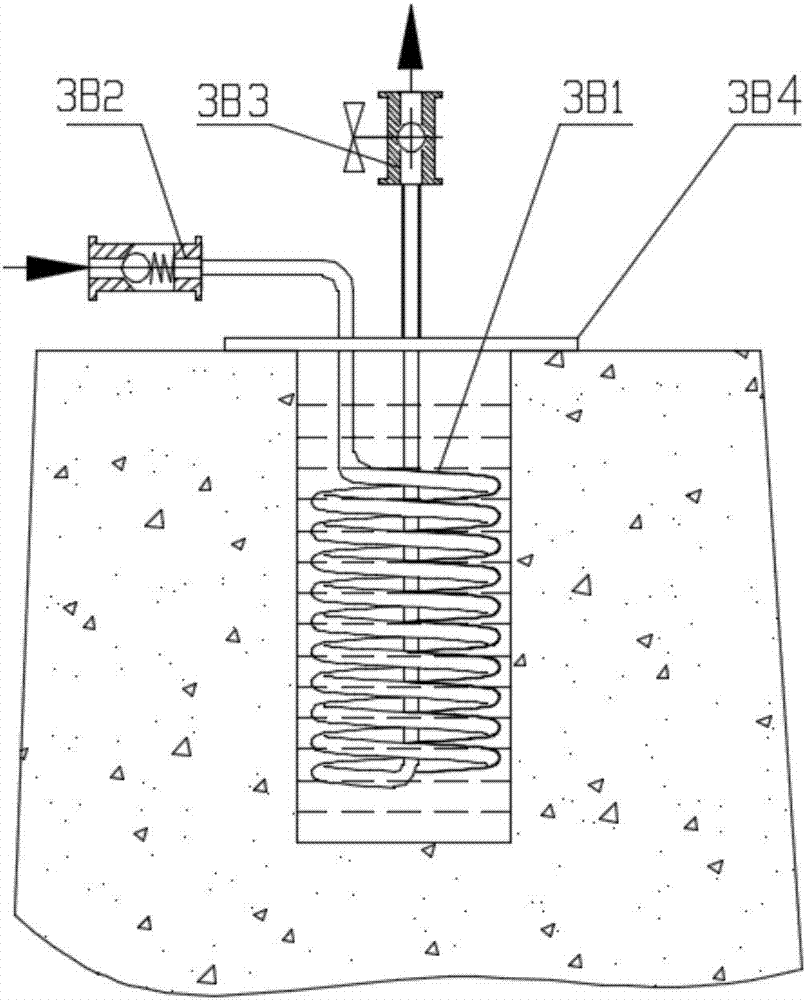

[0055] Such as Figure 1~4 As shown, the present invention provides an equipment system for utilizing geothermal energy to realize carbon dioxide cycle power generation, mainly including liquid CO 2 Storage tank 1, high pressure pump / compressor 2, geothermal energy CO 2 Energy storage device, steady flow regulator 4, turbine / piston expander 5, generator 6, cooler 8, compressor 9, the liquid CO 2 The outlet of the storage tank 1 is connected with the inlet of the high-pressure pump / compressor 2, and the outlet of the high-pressure pump / compressor 2 is connected with the geothermal energy CO 2 The inlet of the energy storage device is connected, and the geothermal energy CO 2 The outlet of the energy storage device is connected with the inlet of the steady flow regulator 4, and the outlet of the steady flow regulator 4 is connected with the inlet of the turbine / piston expander 5, and the turbine / piston expander 5 is connected with the generator 6-shaft connection, the outlet ...

Embodiment 2

[0062] Such as Figure 5 As shown, the difference between Embodiment 2 and Embodiment 1 is that it also includes a regenerator 7; the outlet of the turbine / piston expander 5 is connected to the low-pressure fluid inlet of the regenerator 7, and the low-pressure fluid inlet of the regenerator 7 The fluid outlet is connected to the inlet of the cooler 8, and the outlet of the cooler 8 is connected to the CO 2 The inlet of compressor 9 is connected, CO 2 The outlet of the compressor 9 is respectively connected to the high-pressure fluid inlet of the regenerator 7, the liquid CO 2 The inlet of storage tank 1 is connected. After the turbine or piston expander 5 works and releases energy, low-pressure CO is discharged. 2 Fluid, low pressure CO 2 The fluid recovers waste heat through the regenerator 7 and then cools through the cooler 8, CO 2 Compressor 9 compresses and sends into liquid CO 2 Tank 1 for circulation, or CO 2 The fluid compressed by the compressor 9 enters the g...

Embodiment 3

[0064] Such as Figure 6 As shown, the difference between embodiment 3 and embodiment 1 is that the geothermal energy CO 2 The energy storage device includes two desktop geothermal energy CO 2 The energy storage device 3A also includes a regenerator 7 in the equipment system; the outlet of the high-pressure pump / compressor 2 is respectively connected to two desktop geothermal energy CO 2 The inlet of the energy storage device 3A is connected, and the two desktop geothermal energy CO 2 The outlet of the energy storage device 3A is connected with the inlet of the steady flow regulator 4; the outlet of the turbine / piston expander 5 is connected with the low-pressure fluid inlet of the regenerator 7, and the low-pressure fluid outlet of the regenerator 7 is connected with the cooler The inlet of 8 is connected, and the outlet of cooler 8 is connected with CO 2 The inlet of compressor 9 is connected, CO 2 The outlet of the compressor 9 is respectively connected to the high-pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com