Coal permeability enhancement method for microwave hot air coupled heat injection

A technology of microwave hot air and coal body, which is applied in the direction of mining fluid, earthwork drilling, wellbore/well parts, etc., to achieve the effect of expanding coal seam cracks, good coal seam permeability enhancement, and dredging pores

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

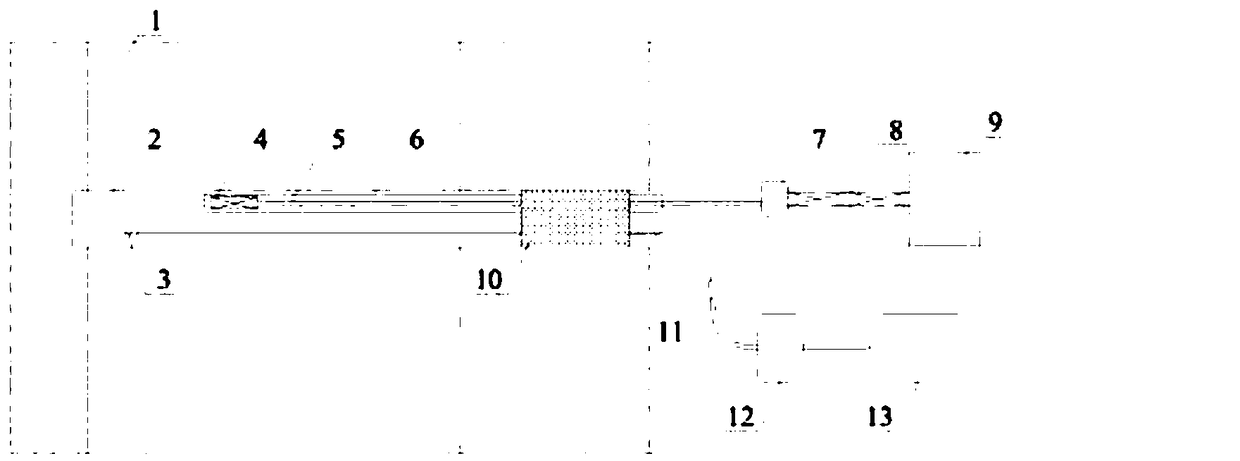

[0019] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

[0020] The coal body anti-reflection method of microwave hot air coupling heat injection of the present invention: first, construct a borehole 2 in the coal seam 1, send into the hot air pipe 3 and the microwave protection pipe 6 in the borehole 2 after the construction is completed, and the hot air The distance between the exposed ends of the tube and the microwave protective tube is 0.1 m from the orifice. The microwave protective tube 6 is made of polytetrafluoroethylene. Afterwards, the microwave antenna 4 is connected to the front end of the coaxial waveguide 5 , and then it is sent into the microwave protection tube 6 until the microwave antenna 4 reaches the inner end of the microwave protection tube 6 . The exposed end of the coaxial waveguide 5 is sequentially connected to the waveguide converter 7, the rectangular waveguide 8 and the microwave ge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com