Dustproof guide sleeve

A technology of guide sleeves and anti-dust rings, which is applied in the direction of laying tracks, roads, tracks, etc., can solve the problems of affecting the up and down movement of guide columns, long-term accumulation, splashing, etc., and achieve the effects of reducing labor intensity, high degree of automation, and improving the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

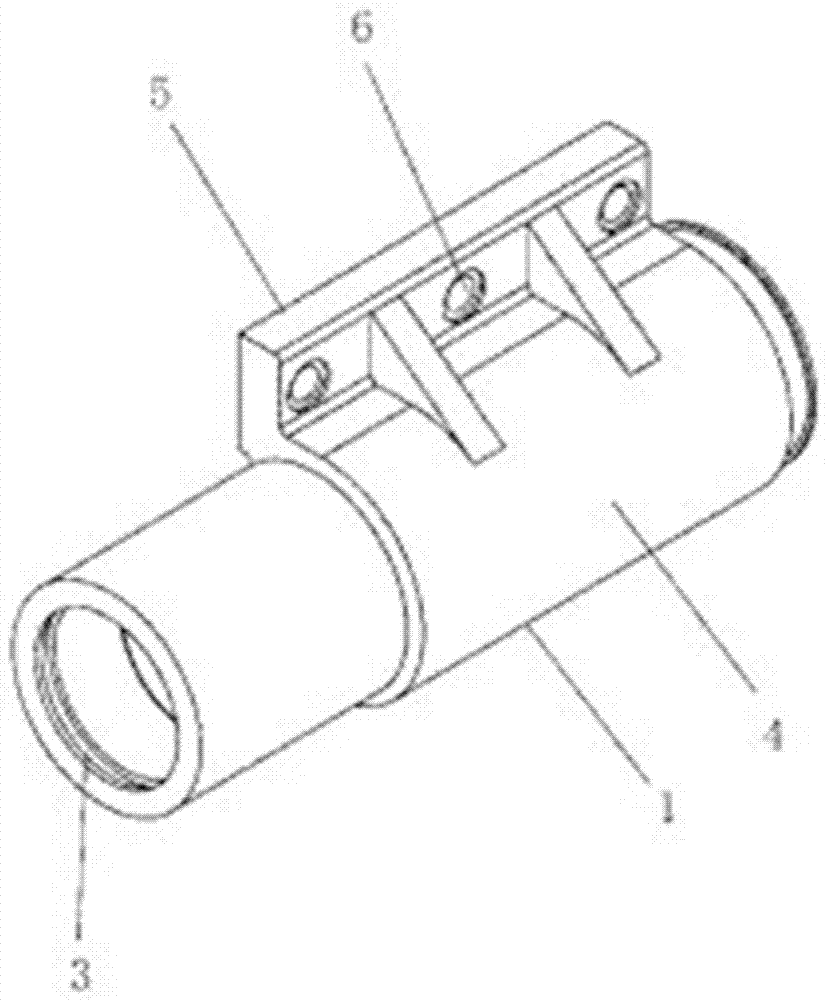

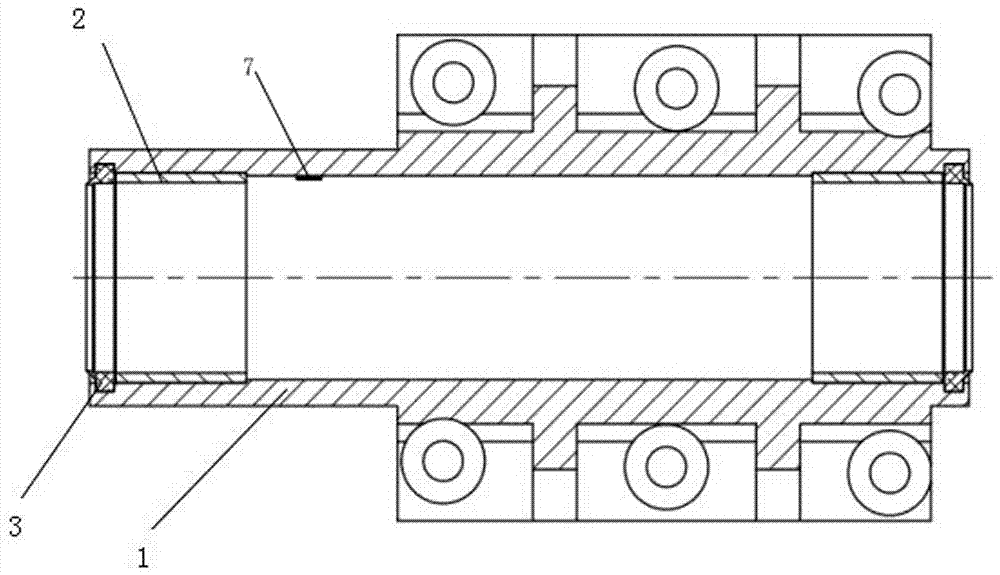

[0035] Such as Figure 1-2 As shown, the dust-proof guide sleeve in this embodiment includes a guide sleeve body 1, and copper-based graphite sleeves 2 are respectively embedded in the two ends of the guide sleeve body 1, and the copper-based graphite sleeve 2 can also be Nylon sleeve, but its wear resistance is not as good as copper sleeve, and the functions realized are actually the same. The outer edge of the copper-based graphite sleeve is provided with a dust-proof ring 3, and the dust-proof ring 3 is also located on the guide sleeve Inside of both ends of the body. Wherein, the guide sleeve body 1 includes a ferrule 4 and a fixing part 5, the ferrule 4 and the fixing part 5 are integrally formed, and the fixing part 5 is separately arranged on both sides of the ferrule 4, but the fixing parts 5 are all located on the same level. In order to be fixed during use, it is fixed through the through hole 6 opened on the fixing part 5. At the same time, in order to cooperate w...

Embodiment 2

[0037] Such as Figure 1-3 As shown, a dust-proof guide sleeve includes a guide sleeve body 1, copper-based graphite sleeves 2 are respectively embedded in the two ends of the guide sleeve body 1, and the outer edge of the copper-based graphite sleeve 2 is provided with an anti-corrosion The dust ring 3 is located inside the two ends of the guide sleeve body 1 . The copper-based graphite sleeve 2 is a graphite copper sleeve. The guide sleeve body 1 includes an integrally formed ferrule 4 and a fixing portion 5 for fixing. The fixing parts 5 are separately arranged on two sides of the ferrule 4, and the fixing parts 5 are located on the same horizontal plane. The fixing part 5 is provided with a through hole 6 for fixing. The axis of the through hole 6 forms an included angle with the horizontal and vertical lines of the axis of the ferrule. The included angle is 1-1.5 degrees.

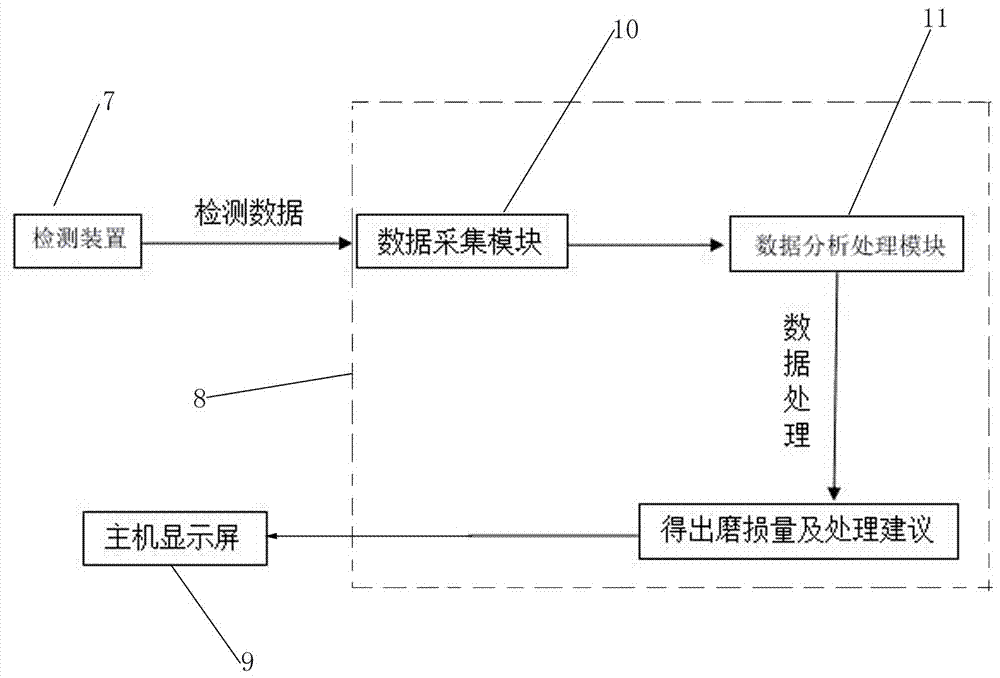

[0038]A detection device 7 is arranged inside the guide sleeve, and the detection device 7 is ...

Embodiment 3

[0040] Such as Figure 1-3 As shown, the dust-proof guide sleeve in this embodiment includes a guide sleeve body 1, and copper-based graphite sleeves 2 are respectively embedded in the two ends of the guide sleeve body 1, and the copper-based graphite sleeve 2 can also be Nylon sleeve, but its wear resistance is not as good as copper sleeve, and the functions realized are actually the same. The outer edge of the copper-based graphite sleeve is provided with a dust-proof ring 3, and the dust-proof ring 3 is also located on the guide sleeve Inside of both ends of the body. Wherein, the guide sleeve body 1 includes a ferrule 4 and a fixing part 5, the ferrule 4 and the fixing part 5 are integrally formed, and the fixing part 5 is separately arranged on both sides of the ferrule 4, but the fixing parts 5 are all located on the same level. In order to be fixed during use, it is fixed through the through hole 6 opened on the fixing part 5. At the same time, in order to cooperate w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com