Novel stentering setting machine

A tenter setting machine, a new type of technology, is used in textiles and papermaking, fabric surface trimming, fabric elongation and other directions, which can solve the problems of inability to accurately adjust, limited angle, oil spillage, etc., to ensure the quality of tenter setting, The effect of reducing heat loss and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

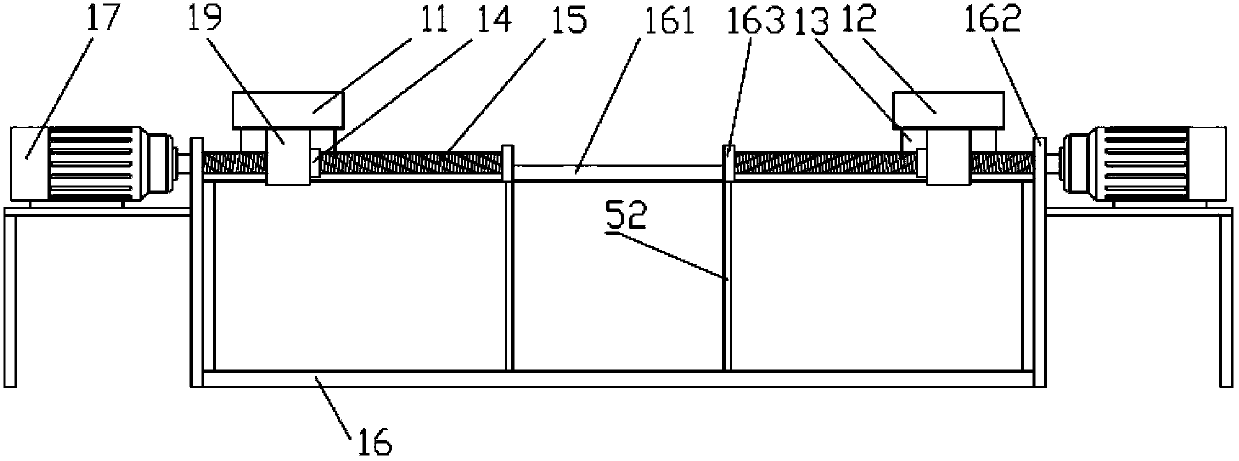

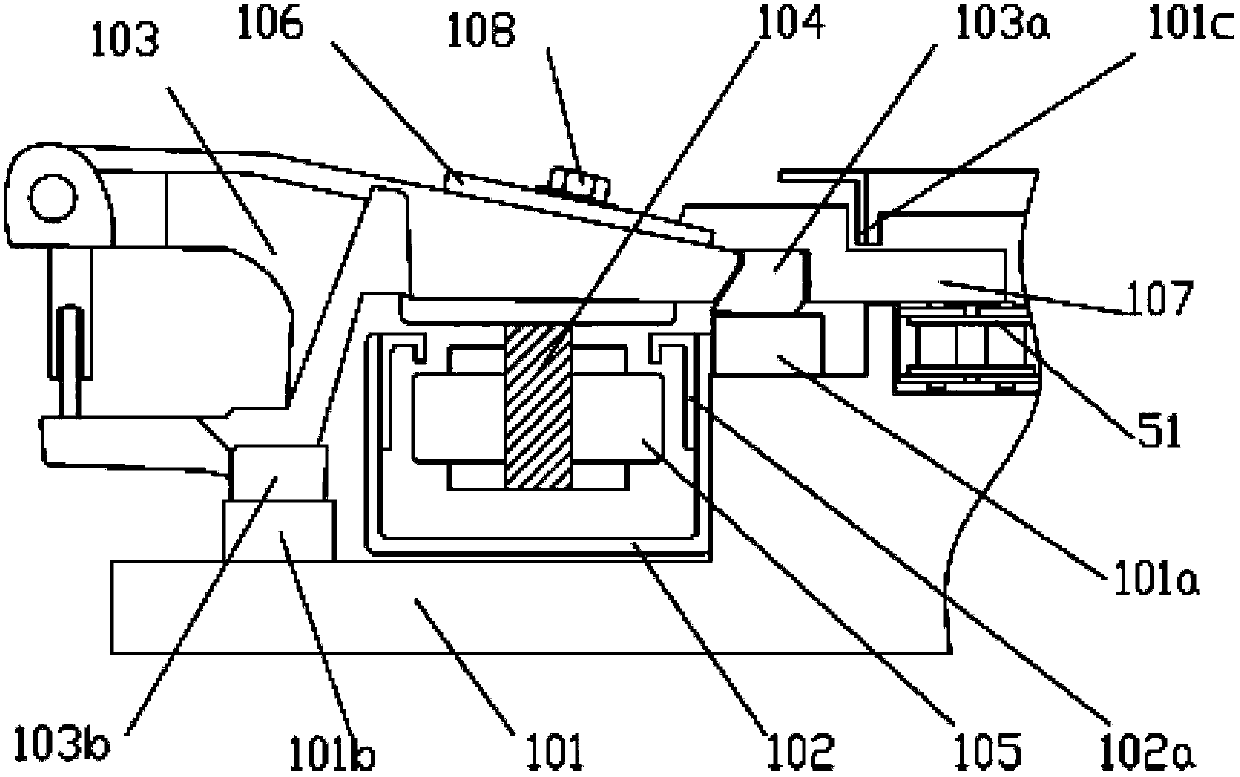

[0034] Example: see Figures 1 to 10 As shown, a new type of stenter setting machine includes a guide device 10, a traction mechanism 20, an operating table 30 and a cloth drop device 40, the guide device 10 is in front of the traction mechanism 20, the cloth fall device 40 is behind the traction mechanism 20, and the operation table 30 is placed between the guide device 10 and the traction mechanism 20, the expanding device 4 is arranged on the guide device 10, the traction mechanism 20 includes a feeding track 1, an oven 2 and a heat exchange device 3, the feeding track 1 passes through the oven 2, and the heat exchange The device 3 is arranged above the oven 2, the exhaust gas outlet pipe 21 of the oven 2 communicates with the exhaust gas inlet pipe 31 of the heat exchange device 3, and the hot air outlet pipe 32 of the heat exchange device 3 communicates with the hot air inlet pipe 22 of the oven 2;

[0035] Feeding track 1 comprises two left guide rails 11 and right guide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com