Preparation method of high-density liquid hydrocarbon fuel

A high-density liquid, hydrocarbon fuel technology, applied in the preparation of liquid hydrocarbon mixtures, biological raw materials, petroleum industry, etc., can solve problems such as rising costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-14

[0028] 1. Preparation of catalyst:

[0029] 1) Preparation of solid acid catalysts: Nafion and Amberlyst resins, Y-type molecular sieves, montmorillonite K-10 and KSF are commercial catalyst products purchased directly.

[0030] Phosphorylated zirconia (ZrP) catalyst is mixed with 1 mol / L zirconium oxychloride and ammonium dihydrogen phosphate aqueous solution at a volume ratio of 2:1, and the obtained precipitate is washed and filtered repeatedly and then dried at 120°C for 10 h. Then baked at 400 °C for 4 h.

[0031] 2) Preparation of solid base catalysts: alkaline earth oxides (MgO, CaO, SrO) and rare earth oxides (La 2 o 3 , CeO 2 ) respectively by the corresponding nitrate in N 2 Calcined under atmosphere for 8h. Alkaline earth and rare earth mixed oxides were added dropwise with 20 wt% ammonia water to two nitrate solutions mixed in a certain molar ratio by co-precipitation method, the pH was adjusted to 9, stirring was continued for 1 h, dried at 80°C overnight, an...

Embodiment 10

[0037] Sedimentation and precipitation method: prepare 0.14M nickel nitrate solution and divide it into two parts A and B in equal volume, and add one of H-ZSM-5, H-MOR, silicon-aluminum composite carrier, H-β molecular sieve, and alumina to A and an appropriate amount of concentrated nitric acid, add 0.42 M urea to B, slowly drop B into A in a water bath at 80°C, stir for 10 h after raising the temperature to 90°C, filter and wash, dry at 80°C overnight, and roast in air at 500°C for 2 h. The catalyst was reduced in situ with hydrogen at 500 °C for 2 h in a fixed bed. (see table 1, embodiment 11-15)

Embodiment 11-15

[0038] Table 1 Supported metal A / X type bifunctional catalyst

[0039]

[0040] 2. Aldol condensation reaction: In a fixed-bed reactor, put 1.0 g of catalyst into the reaction tube, keep the pressure in the reactor at 0.1 MPa, and the hydrogen flow rate at 150 mL / min. Pump into the reactor at 0.10 mL / min. The reaction results are shown in Table 2.

[0041] Table 2 Cyclopentanone Aldol Condensation Results

[0042]

[0043]

[0044] Table 3 Aldol condensation reaction target product structure

[0045]

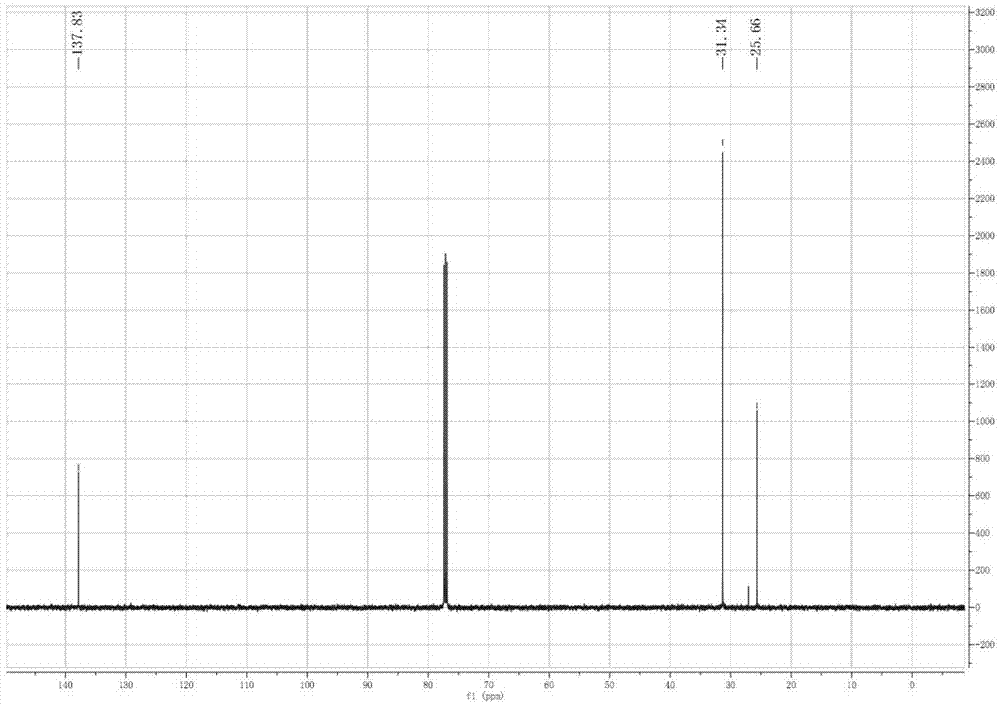

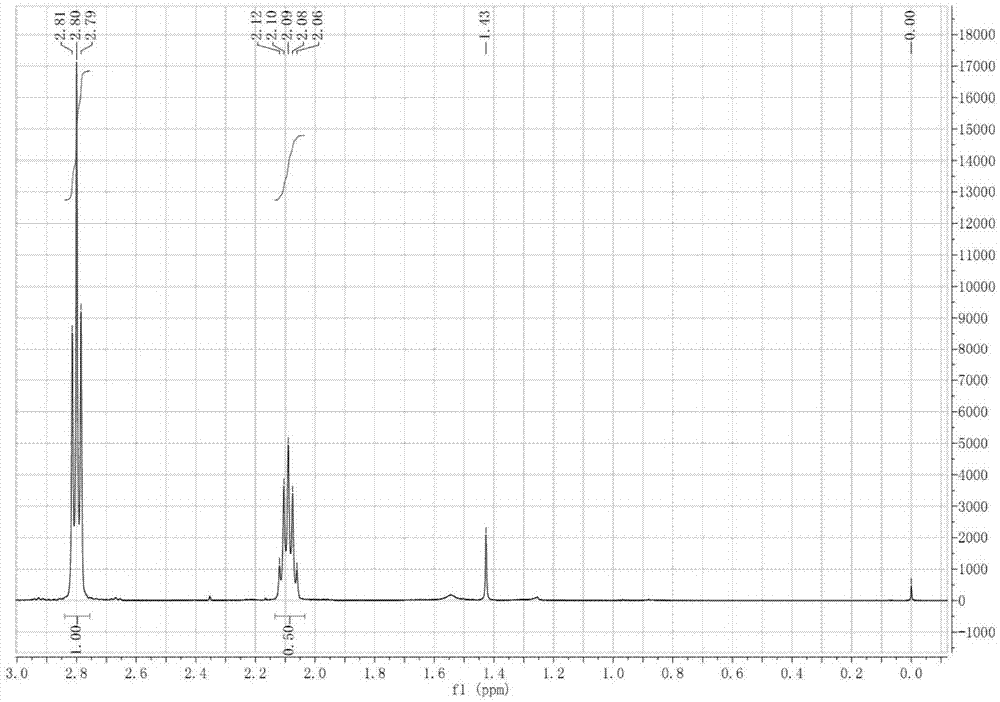

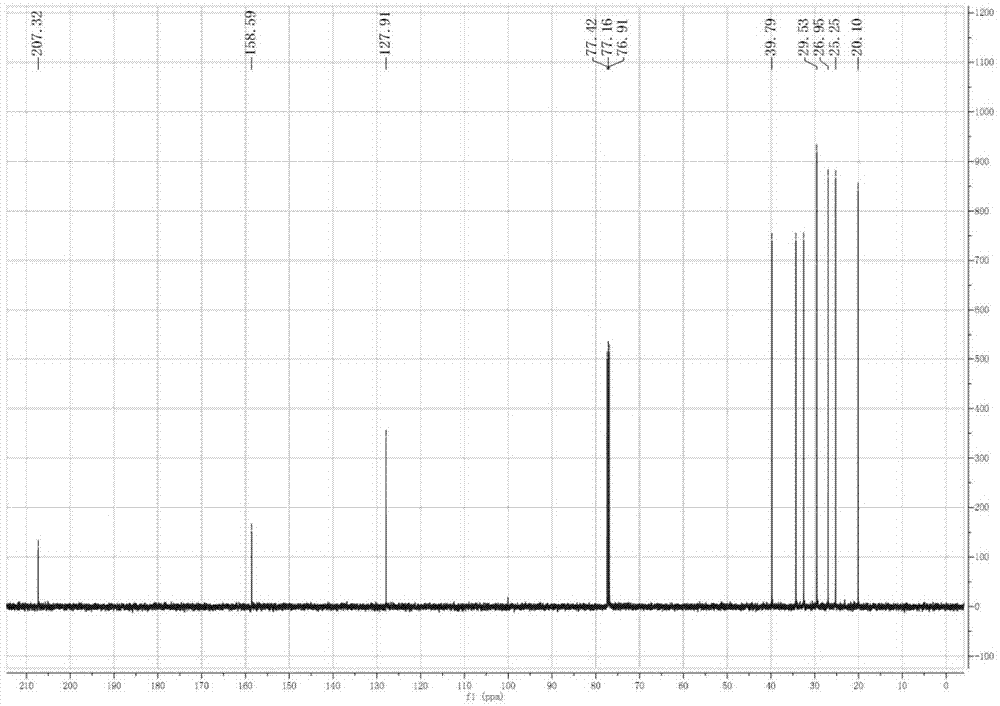

[0046] As can be seen from Table 2, under the action of a solid acid catalyst, the dimer and trimer of cyclopentanone are easy to continue to condense to generate high polymers; , Tripolymer-based. Among them, solid alkali magnesium aluminum hydrotalcite, lithium aluminum hydrotalcite terpolymer (C 15 Tricycloalkane precursor) yield is higher. Figure 1-4 The C-HMR and H-NMR charts of cyclopentanone trimerization and dimerization products, respectively, prove t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com