Room temperature curing polyurethane bonding agent system for PBX (polymer bonded explosive) casting explosives

A room temperature curing, polyurethane technology, applied in the direction of explosives, etc., can solve the problems of easy sedimentation of solid components and high molding temperature, and achieve the effects of inhibiting solid phase sedimentation, reducing temperature requirements, and improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

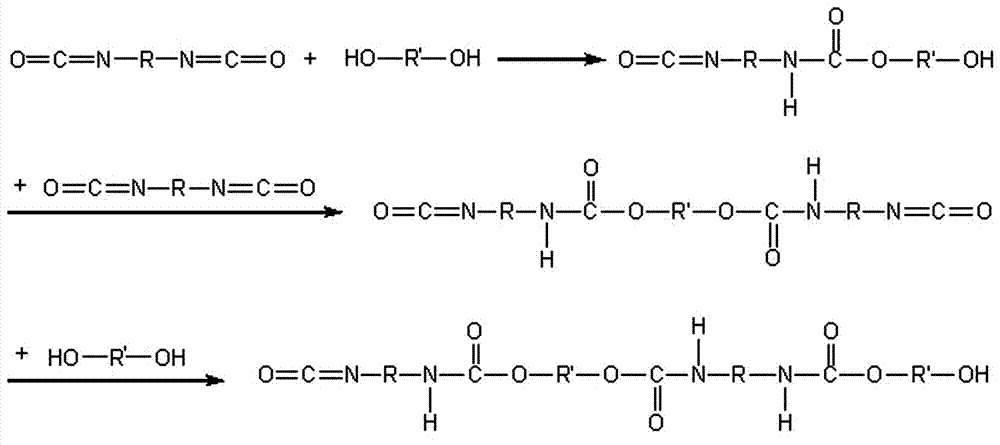

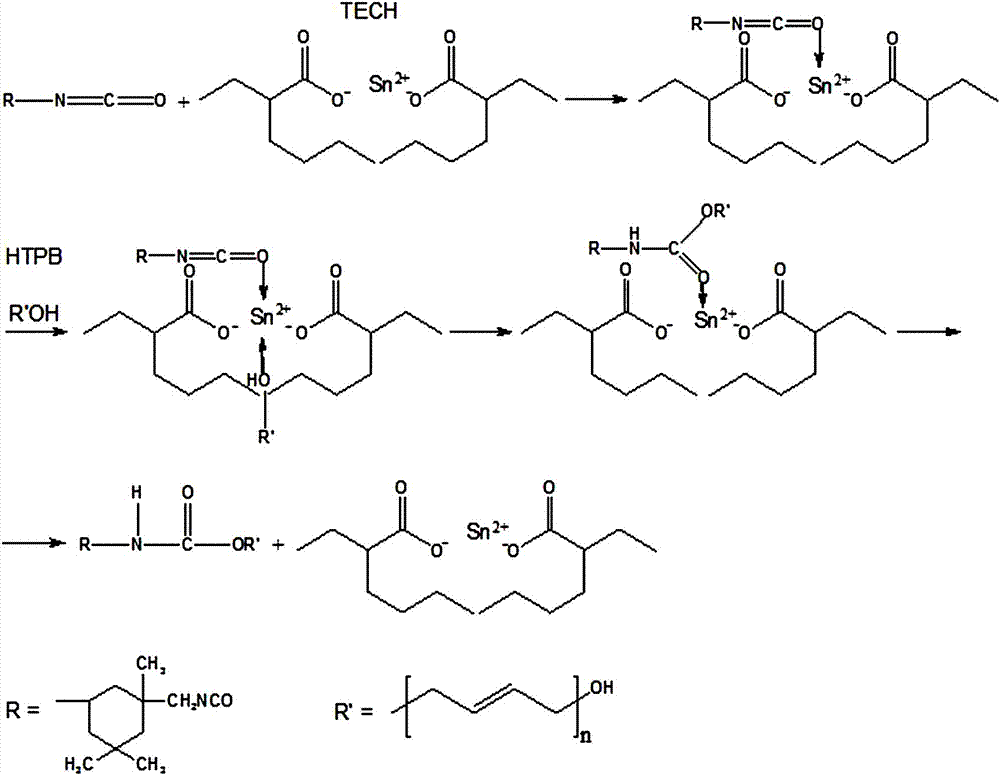

Method used

Image

Examples

Embodiment 1

[0017] Example 1: A room-temperature-curing polyurethane adhesive system for PBX cast explosives, made of the following raw materials: 40 g of hydroxyl-terminated polybutadiene, 40 g of plasticizer isodecyl nonanoate IDP, 1,5-naphthalene Diisocyanate NDI 5g, stannous octoate TECH 0.25g, the construction period is 4h, suitable for pouring of large-sized powder columns.

[0018] The specific preparation method is: accurately weigh the hydroxyl-terminated polybutadiene and isodecyl nonanoate, add it to a dry beaker, and add the catalyst TECH at the same time; use a digital display electric mixer to stir at high speed for 5 minutes (1000rpm), and then add the curing agent 1 , 5-naphthalene diisocyanate, continue to stir for 1min, so that the components of the binder system are fully mixed, after the stirring is completed, put the beaker into a vacuum desiccator and vacuumize for 2min under the condition of a vacuum of 0.01MPa to remove air bubbles. After the components of the pour...

Embodiment 2

[0019] Embodiment 2: a kind of room temperature curing polyurethane adhesive system for PBX pouring explosives is made of the raw materials of following weight: 45g of hydroxyl-terminated polybutadiene, 50g of plasticizer butyl nitrate ethyl nitramine, terephthalate Isocyanate 7g, nano-ZnO0.35g,

[0020] The specific preparation method is as follows: accurately weigh the hydroxyl-terminated polybutadiene, butyl nitrate ethyl nitramine, add it to a dry beaker, and add the catalyst nano-ZnO at the same time; use a digital electric mixer to stir at high speed for 8 minutes (200rpm), Then add the curing agent p-phenylene diisocyanate and continue to stir for 2 minutes to fully mix the components of the binder system evenly. After the stirring is completed, put the beaker into a vacuum desiccator and evacuate for 5 minutes under the condition of a vacuum of 0.03MPa to remove air bubbles. After the components of the pouring explosives are fully mixed and uniform, pour them into shap...

Embodiment 3

[0021] Embodiment 3: a kind of room temperature curing polyurethane adhesive system for PBX pouring explosives is made of the following raw materials: 50g of hydroxyl-terminated polybutadiene, 60g of plasticizer isodecyl nonanoate, xylylene di Isocyanate 10g, DABCO 0.5g,

[0022] The specific preparation method is: accurately weigh the hydroxyl-terminated polybutadiene and isodecyl nonanoate, add it into a dry beaker, and add the catalyst DABCO; For dimethylene diisocyanate, continue to stir for 3 minutes to fully mix the components of the binder system evenly. After the stirring is completed, put the beaker into a vacuum desiccator and vacuumize for 1 minute at a vacuum degree of 0.05 MPa to remove air bubbles. After the components of the pouring explosives are fully mixed and uniform, pour them into shape at room temperature, and o Under the condition of curing temperature of C, the curing time is 5-7 days, and a good quality PBX cast explosive column is formed after curing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com