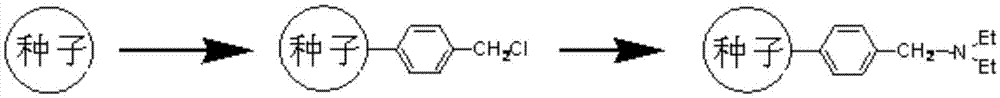

Preparation method for porous polymer microsphere anion filling material

A technology of polymer microspheres and anions, used in chemical instruments and methods, other chemical processes, etc., can solve the problems of unreliable particle size control methods, uneven particle size distribution, and easily broken microspheres, and achieve uniform particle size. And controllable, increase retention time, and the effect of less solvent consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Dissolve 5g of polystyrene / divinylbenzene microspheres in 50ml of toluene, stir and swell at room temperature for 3h, cool to room temperature, add 20ml of chloromethyl ether and 2ml of tin chloride, continue stirring at room temperature for 3h, add deionized water to terminate the reaction , washed with hydrochloric acid, tetrahydrofuran, acetone, set aside.

[0034] Take 5.4g of the above-mentioned chloromethylated microspheres, add them into 108ml of chloroform, add 40ml of ethylenediamine, stir and heat to 150°C, and react for 6h. Cool down to room temperature, treat with acetone, water, methanol, and dry in vacuo.

[0035] Take 2.4 g of the above-mentioned ethylenediamine microspheres in 120 ml of toluene, add 6 g of triethylamine, 1.5 g of acetic anhydride, and 15 g of 4-dimethylaminopyridine, and stir overnight at room temperature. Treat with methanol, water, acetone and dry in vacuo.

[0036] image 3 Electron micrographs of polymer microspheres with various ...

Embodiment 2

[0038] Dissolve 5g of polystyrene / divinylbenzene microspheres in 100ml of toluene, stir and swell at room temperature for 3h, cool to room temperature, add 20ml of chloromethyl ether and 4ml of tin chloride, continue stirring at room temperature for 3h, add deionized water to terminate the reaction , washed with hydrochloric acid, tetrahydrofuran, acetone, set aside.

[0039]Take 5.4g of the above-mentioned chloromethylated microspheres, add them into 216ml of chloroform, add 40ml of ethylenediamine, stir and heat to 150°C, and react for 6h. Cool down to room temperature, treat with acetone, water, methanol, and dry in vacuo.

[0040] Take 2.4 g of the above-mentioned ethylenediamine microspheres in 120 ml of toluene, add 6 g of triethylamine, 1.5 g of acetic anhydride, and 30 g of 4-dimethylaminopyridine, and stir overnight at room temperature. Treat with methanol, water, acetone and dry in vacuo.

Embodiment 3

[0042] Dissolve 5g of polystyrene / divinylbenzene microspheres in 100ml of toluene, stir and swell at room temperature for 3h, cool to room temperature, add 30ml of chloromethyl ether and 2ml of tin chloride, continue stirring at room temperature for 3h, add deionized water to terminate the reaction , washed with hydrochloric acid, tetrahydrofuran, acetone, set aside.

[0043] Take 5.4g of the above-mentioned chloromethylated microspheres, add them into 54ml of chloroform, add 40ml of ethylenediamine, stir and heat to 150°C, and react for 6h. Cool down to room temperature, treat with acetone, water, methanol, and dry in vacuo.

[0044] Take 2.4 g of the above-mentioned ethylenediamine microspheres in 100 ml of toluene, add 6 g of triethylamine, 1.5 g of acetic anhydride, and 45 g of 4-dimethylaminopyridine, and stir overnight at room temperature. Treat with methanol, water, acetone and dry in vacuo.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com