Method for producing dimethyl carbonate by urea alcoholysis method

A technology of dimethyl carbonate and urea alcohol, which is applied in the preparation of carbonate/haloformate, chemical instruments and methods, and the preparation of urea derivatives, etc. It can solve the problem of difficult precise control of propylene glycol stripping time and rapid price changes , Reduce the yield of propylene glycol and other issues, achieve the effect of improving the conversion rate of urea and product yield, reducing the generation of by-products, and solving the high cost of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

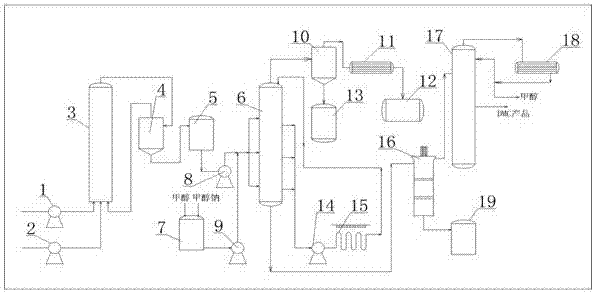

Image

Examples

Embodiment 1

[0029] Embodiment 1 utilizes the method of urea alcoholysis to produce dimethyl carbonate

[0030] Proceed as follows:

[0031] (1) Preparation of urea with carbon dioxide and liquid ammonia as raw materials: inject preheated carbon dioxide and liquid ammonia (preheated to 40°C) into the urea synthesis tower with a pump, and react for 0.5 hours at 140°C and 13 MPa pressure ; The urine synthesized from the urea synthesis tower is decomposed, recovered, and evaporated under reduced pressure to obtain molten urea liquid for subsequent use.

[0032](2) Using urea (the molten urea prepared above) and methanol as raw materials (the molar ratio of methanol to urea is 2.5:1), in an alkaline composite liquid catalyst (composed of methanol solution of methylamine and sodium methylate, formaldehyde Amine accounts for 35%, and sodium methylate accounts for 15%, and methyl alcohol accounts for 50%. The consumption of alkaline composite liquid catalyst is 5% of methanol weight) direct reac...

Embodiment 2

[0034] Embodiment 2 utilizes the method of urea alcoholysis to produce dimethyl carbonate

[0035] Proceed as follows:

[0036] (1) Preparation of urea with carbon dioxide and liquid ammonia as raw materials: inject preheated carbon dioxide and liquid ammonia (preheated to 40°C) into the urea synthesis tower with a pump, and react for 0.5 hours at 140°C and 13 MPa pressure ; The urine synthesized from the urea synthesis tower is decomposed, recovered, and evaporated under reduced pressure to obtain molten urea liquid for subsequent use.

[0037] (2) Using urea (the molten urea prepared above) and methanol as raw materials (the molar ratio of methanol to urea is 2.5:1), in an alkaline composite liquid catalyst (composed of methanol solution of methylamine and sodium methylate, formaldehyde Amine accounts for 30%, sodium methoxide accounts for 20%, and methyl alcohol accounts for 50%. The consumption of alkaline composite liquid catalyst is 6% of methanol weight) direct reactio...

Embodiment 3

[0039] Embodiment 3 utilizes the method for urea alcoholysis to produce dimethyl carbonate

[0040] Proceed as follows:

[0041] (1) Preparation of urea with carbon dioxide and liquid ammonia as raw materials: inject preheated carbon dioxide and liquid ammonia (preheated to 40°C) into the urea synthesis tower with a pump, and react for 0.5 hours at 140°C and 13 MPa pressure ; The urine synthesized from the urea synthesis tower is decomposed, recovered, and evaporated under reduced pressure to obtain molten urea liquid for subsequent use.

[0042] (2) With urea (the molten urea prepared above) and methanol as raw materials (the molar ratio of methanol to urea is 3:1), in an alkaline composite liquid catalyst (composed of methanol solution of methylamine and sodium methylate, formaldehyde Amine accounts for 25%, and sodium methylate accounts for 25%, and sodium methylate accounts for 50%. The consumption of alkaline composite liquid catalyst is 8% of methanol weight) direct rea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com