No-firing high purity magnesium calcium brick and preparation method therefor

A pure magnesia-calcium brick, high-purity technology, applied in the field of refractory materials, can solve the problems of affecting the atmospheric environment, natural gas explosion, high cost of natural gas, etc., achieve the effects of reducing impurity content, strong oxidation resistance, and prolonging the life of the furnace lining

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] The raw materials were weighed according to the components specified in Table 1 below, and the preparation method was as follows.

[0038] (1) Weigh high-purity fused magnesia, sintered magnesia and magnesia-calcium sand according to parts by weight, put them into a crusher for crushing, and then add them to a ball mill for crushing, and then use a vibrating screen to screen out a particle size of Aggregate with a particle size of 100-150 mesh;

[0039] (2) Weigh high-purity fused magnesia powder, binder solid powder, rare earth oxide and ceramic sintering agent into a container by weight and mix them to form a powder;

[0040] (3) Mixing: Put the prepared aggregate into the mud mixer, add vitrified binder, the rotation speed is 50-60r / min, and the stirring time is 10-20 minutes. When stirring, add liquid binder until the vitrified binder is wrapped On the surface of the aggregate, add the powder prepared in the above step (2) and continue mixing and stirring for 20-30...

Embodiment 2

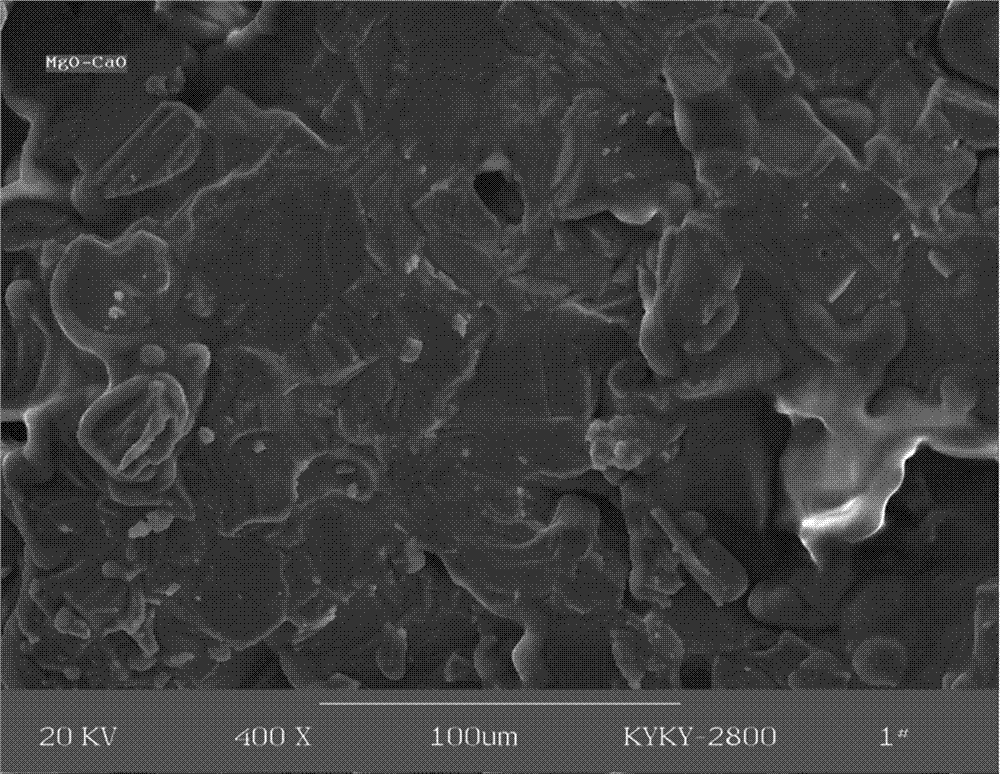

[0045] The method of Example 1 was repeated at the contents of each component specified in Table 1 below, and the test results are listed in Table 2. The unfired high-purity magnesia-calcium brick prepared in Example 2 was calcined at 1750° C. for 24 hours. Scanning electron micrographs of fractures of residual bricks after calcination are shown in 5 and Figure 6 shown.

Embodiment 3

[0047] The method of Example 1 was repeated at the contents of each component specified in Table 1 below, and the test results are listed in Table 2.

[0048] Table 1 Raw material ratio table of Examples 1-3 of the present invention.

[0049]

[0050] 1. Performance testing.

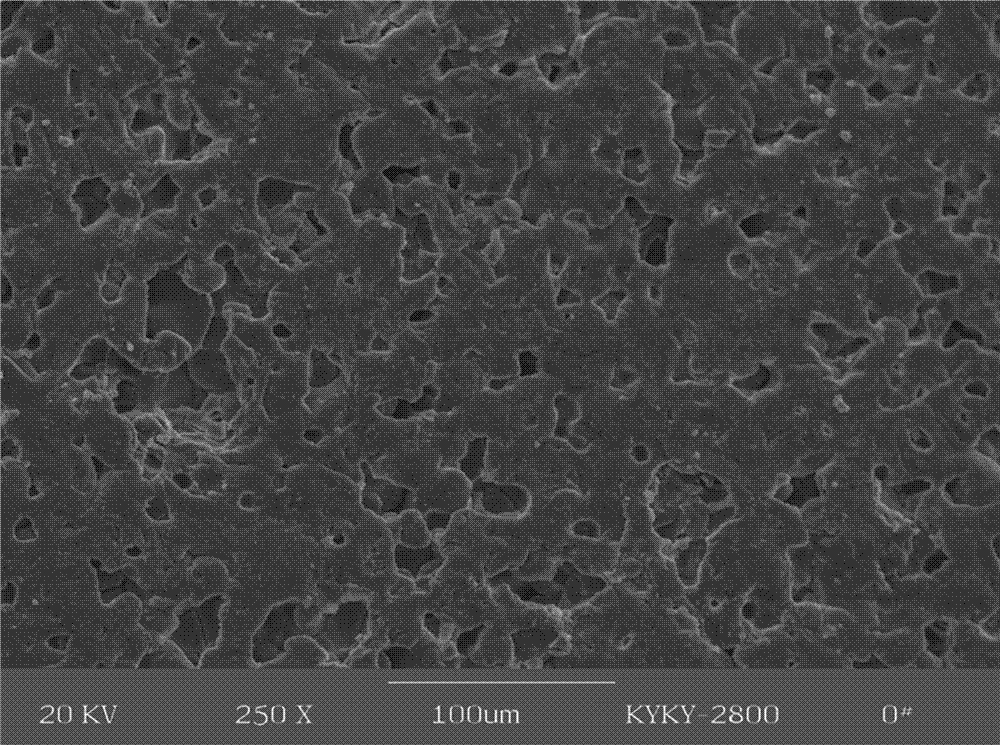

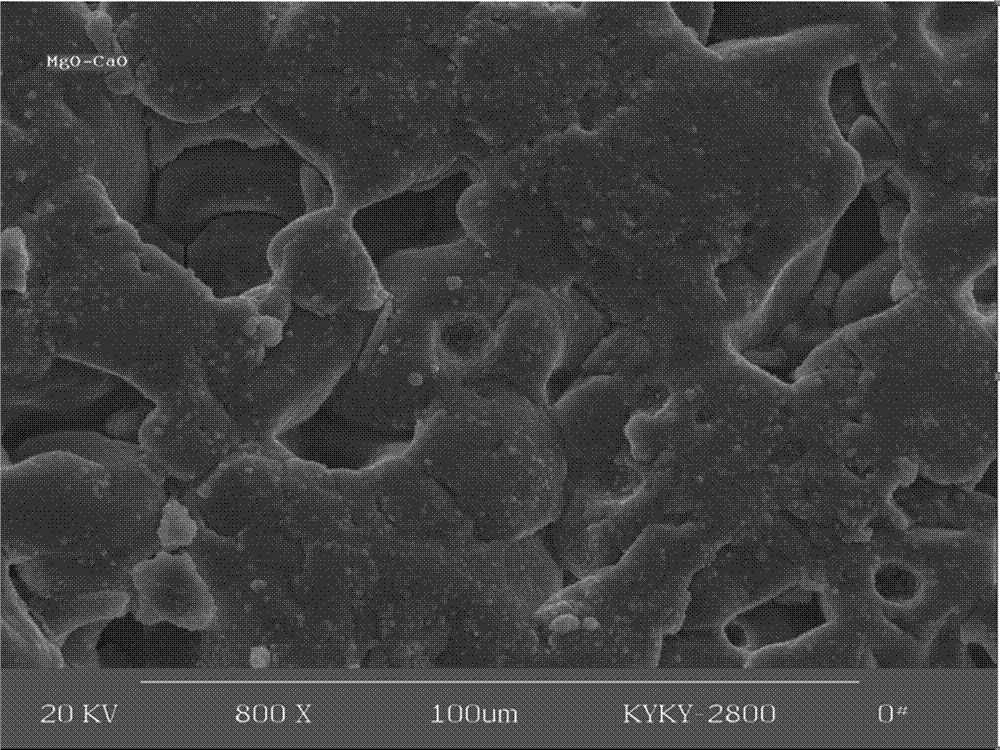

[0051] 1. Carry out scanning electron microscope to embodiment 2 of the present invention, the result is as follows Figures 1 to 6 shown.

[0052] The polishing scanning electron microscope figure ( Figure 7 and Figure 8 ) shown; the present invention randomly selects the non-fired high-purity magnesia-calcium bricks prepared in Example 2 for electron microscope scanning, as Figure 1-4 Shown; The unfired high-purity magnesia-calcium brick prepared in Example 2 was calcined at 1750° C. for 24 hours. Scanning electron micrographs of fractures of residual bricks after calcination are shown in 5 and Figure 6 show; combine Figure 1-8 It can be seen from the display that the scanning electron mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com