Treatment system and treatment method of oil refinery alkaline residue wastewater

A technology of alkali slag wastewater and treatment system, which is applied in natural water body treatment, multi-stage water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problem of high cost of treatment technology, and achieve enhanced growth adaptability and cost The effect of reducing and eliminating hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

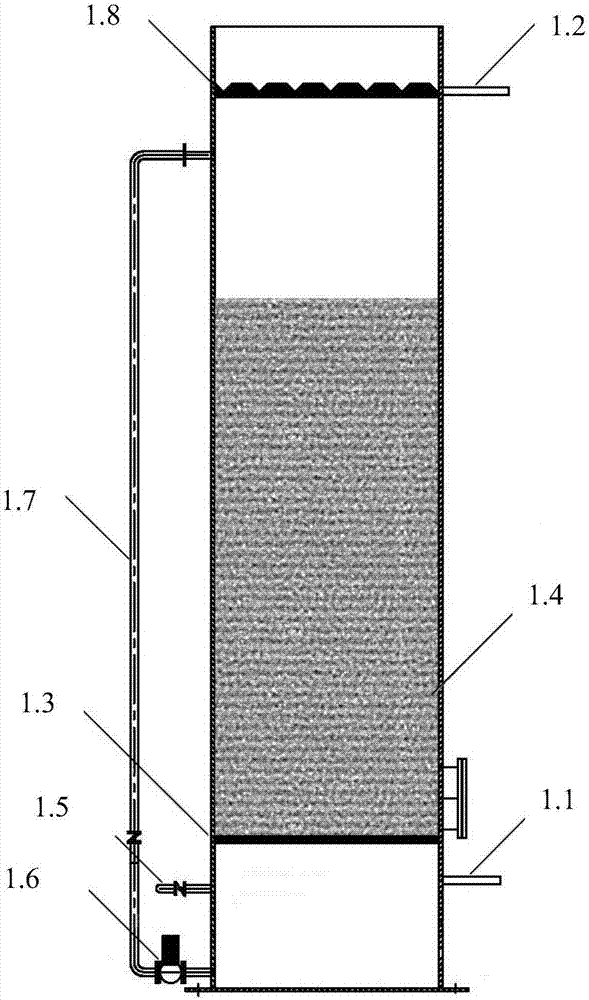

[0037] Such as Figure 1-6 As shown, the internal circulation micro-gradient biological oxidation combined treatment system for the treatment of refinery alkali slag wastewater consists of a waste alkali storage tank, a denitrification reactor, two internal circulation aerobic bioreactors, a nitrification reactor, and an ozone catalytic reactor and nitrification reactors. The waste caustic storage tank is connected to the denitrification reactor, and there are alkali residue metering pumps, dilution water metering pumps, acid liquid metering pumps, nutrient salt metering pumps and nitrification liquid return pumps on the connecting pipeline between the waste caustic soda storage tank and the denitrification reactor . Two internal circulation aerobic bioreactors are set up in parallel, the denitrification reactors are respectively connected to the internal circulation aerobic bioreactors through pipelines, the internal circulation aerobic bioreactors are connected to the biolo...

Embodiment 2

[0044] The treatment method of the internal circulation micro-gradient biological oxidation combined treatment system of Example 1 of the present invention is as follows:

[0045] The spent alkali storage tank is connected to the denitrification reactor through the alkali slag metering pump, and the dilution water metering pump, the acid liquid metering pump, the nutrient salt metering pump and the nitrification liquid return pump are arranged on the connecting pipeline. After metering, the waste caustic liquor is mixed with dilution water in a certain proportion, and the mixed sewage is mixed and diluted again with the reflux water from the nitrification reactor at the end of the device. At this time, the COD of the total mixed sewage is controlled within the range of design requirements (usually COD≈3000mg / L or so). Add concentrated sulfuric acid to the pipeline for neutralization, control the pH of the total mixed sewage in the range of 8.5 to 10.5, and add sodium dihydrog...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com