Kitchen knife edge polishing device and method

A technology for knives and kitchens, applied in the field of processing equipment for kitchen knives, can solve the problems of thick cutting edge lines, easy burning of the cutting edge, and uneven deformation of the cutting edge.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

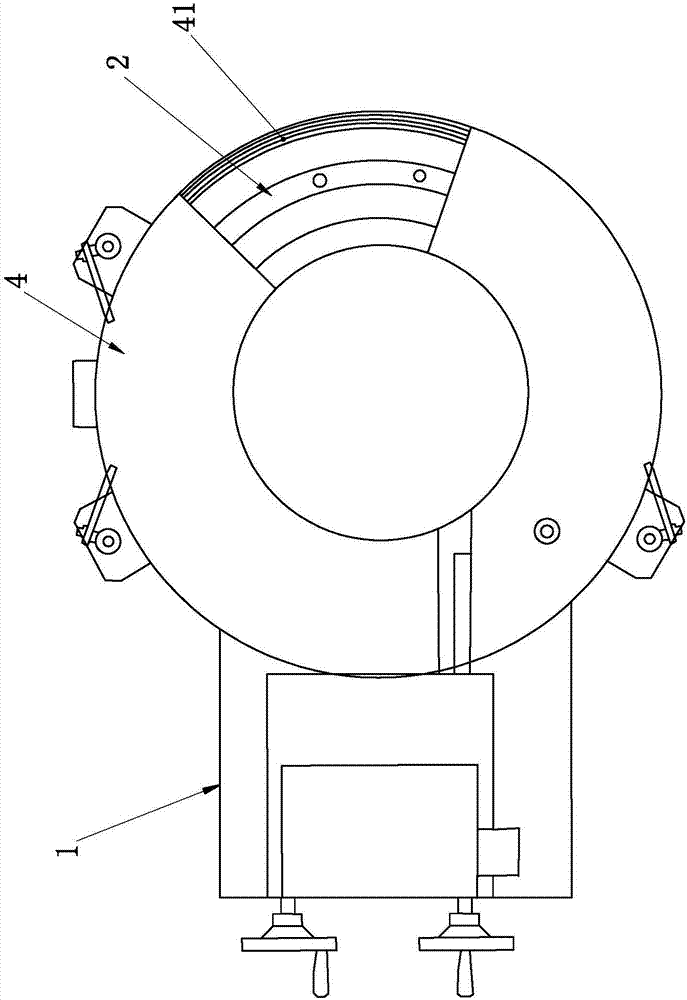

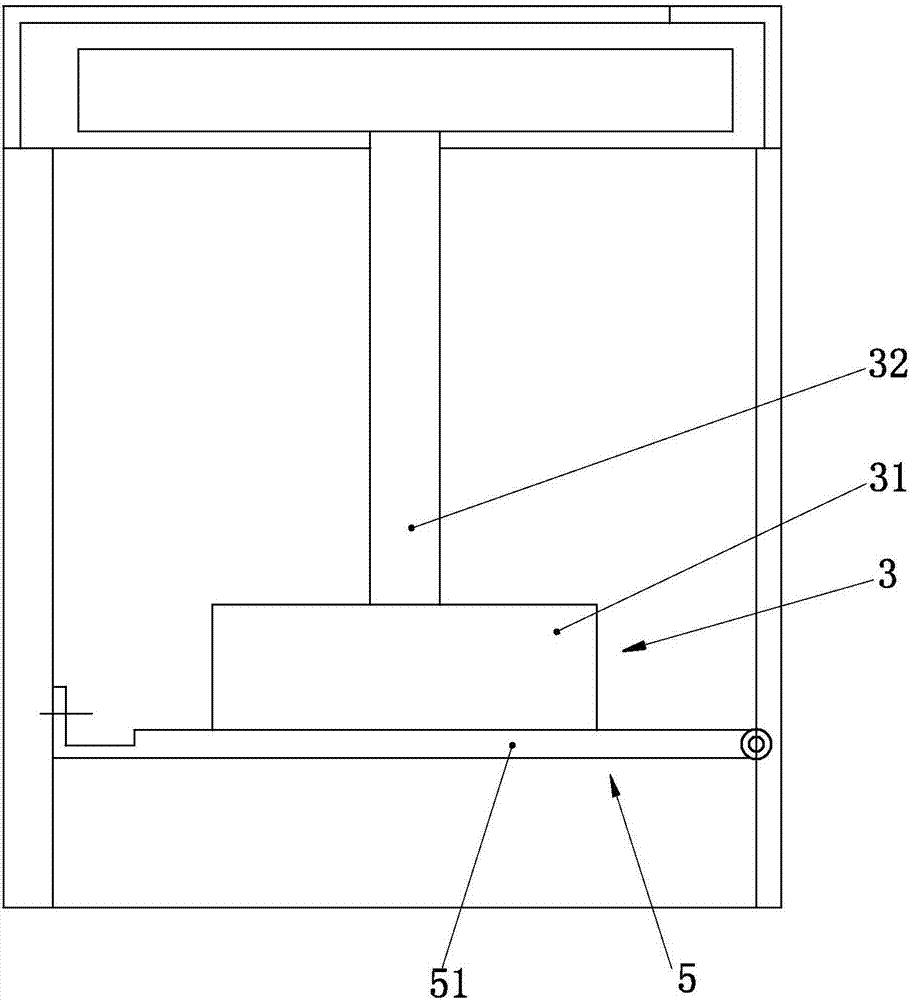

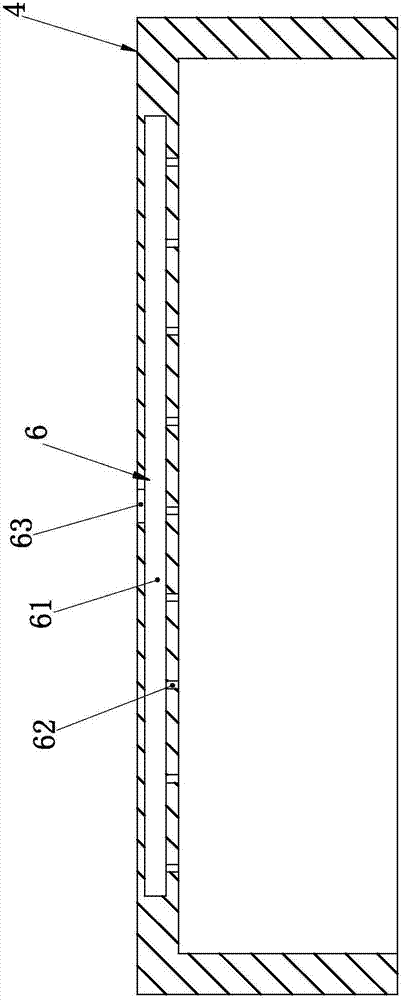

[0017] Such as figure 1 — image 3 The shown kitchen knife sharpening equipment includes an organic body 1, a grinding wheel 2 arranged on the body 1, a drive assembly 3 for driving the rotation of the grinding wheel 2, a protective cover 4 arranged outside the grinding wheel 2, and a device for adjusting the angle of the grinding wheel 2 Angle adjustment mechanism 5, one side of protective cover 4 is provided with the grinding opening 41 that enters the grinding wheel 2 for kitchen knives, and the cooling mechanism 6 corresponding to grinding wheel 2 is provided in protective cover 4 on body 1. In the above technical solution, the cutting edge of the kitchen knife is polished by using the grinding wheel 2. Since the sand grains of the grinding wheel 2 are finer, the lines of the cutting edge of the kitchen knife after grinding are thinner, so that the cutting edge after grinding is sharper; By arranging the cooling mechanism 6 on the body 1, the cutting edge of the kitchen k...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com