Preparation method of aminated thiolignin-based strong oil absorption material

A technology of aminated lignin and lignin-based, which is applied in the field of preparation of oil-absorbing materials, can solve the problems of poor surface activity of modified lignin amine, low three-dimensional network chemical cross-linking structure, water absorption and oil absorption performance interference, etc. Achieve the effect of uncomplicated treatment method, simple recycling process and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

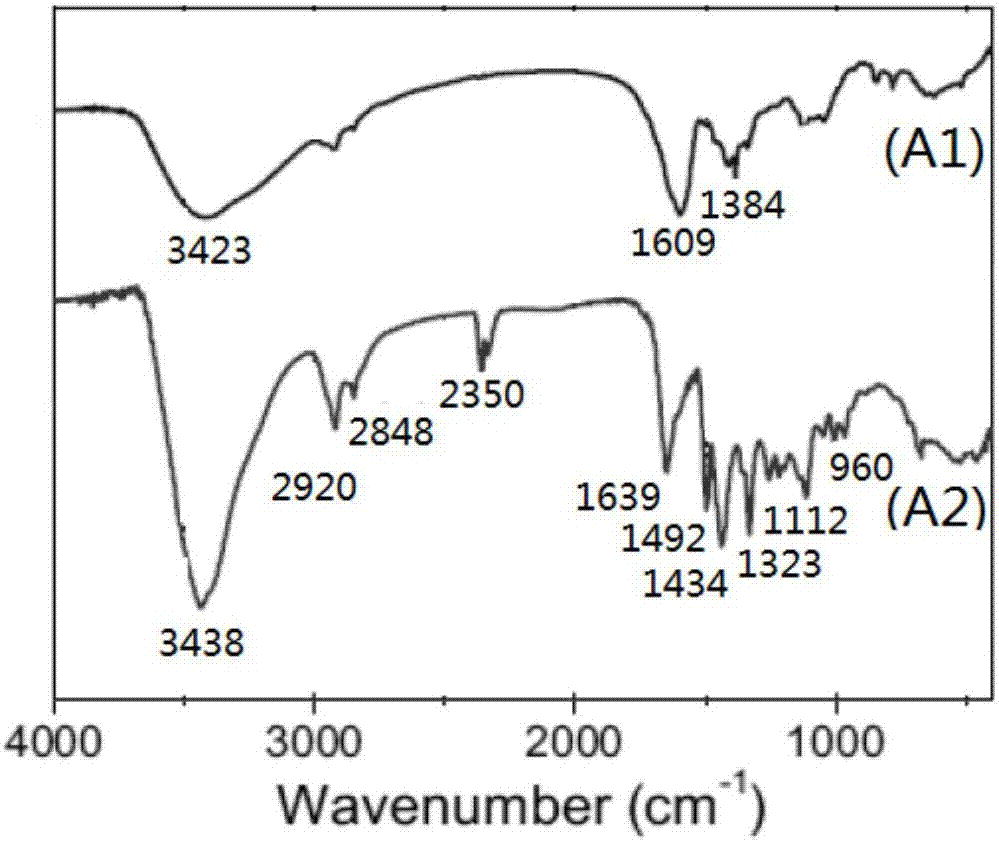

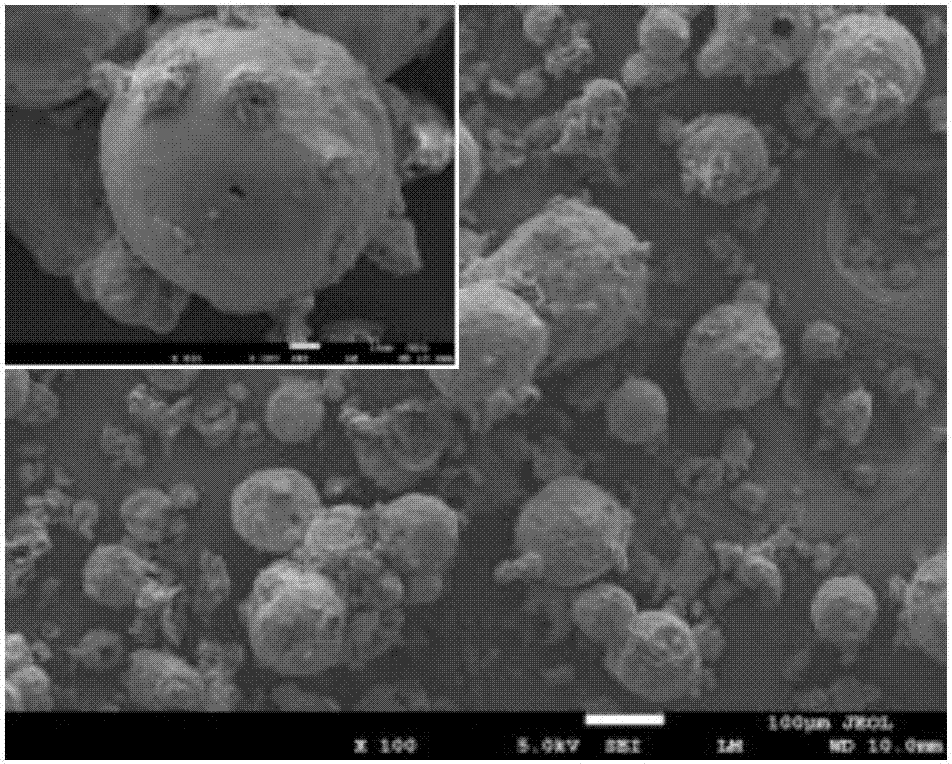

Embodiment 1

[0025] Take a 250mL three-necked flask, dissolve 20g of lignin (about 0.1mol according to the C9 unit, the same below) in 50mL of NaOH solution (concentration 1mol / L), stir well, put it into a microwave reactor, set the temperature to 40 Under the conditions of ℃, reaction pressure 1MPa, microwave power 400W, heat up to the preset temperature, add 0.1mol of aminating agent diethylenetriamine (DETA), then slowly drop 5mL (about 0.1mol) of 37wt% formaldehyde solution, reflux and stir , so that the active hydrogen of the methoxy group on the lignin, the active oxygen on the formaldehyde, and the active hydrogen connected to the nitrogen on the aminating agent take place Mannich reaction (Mannish reaction), after the insulation reaction for 20 minutes, the reaction solution is poured into 80 In hot distilled water at ℃, add 1mol / L hydrochloric acid solution dropwise under stirring to fully separate the aminated lignin, let it stand for 3 hours, filter, wash with 0.1mol / L dilute hyd...

Embodiment 2

[0029] Aminated lignin A was prepared as in Example 1. Take 4g of vulcanizing agent CS2 (0.1mol) and slowly add it to the suspension of aminated lignin A (mass concentration 10%) dissolved in pyridine solvent, wherein the molar ratio of CS2 to aminated lignin B is about 1:1.40 The reaction was stirred and reacted at ℃ for 48 hours, and the product was cooled to room temperature, filtered, washed with ethanol solvent, washed with distilled water, and dried at 80℃ for 5 hours to obtain a solid substance which was a thioaminated lignin-based strong oil-absorbing material B (mass yield 97.3% ).

[0030] The commercial oil-absorbing resin materials butyl acrylate and octadecyl acrylate polymer were used as the control sample C to carry out the chloroform adsorption test experiment, and 0.1g of the above-mentioned composite oil-absorbing material B and control sample C were weighed and placed in a 100mL grinding mouth drying cone Add 50mL of distilled water to soak in a shaped bott...

Embodiment 3

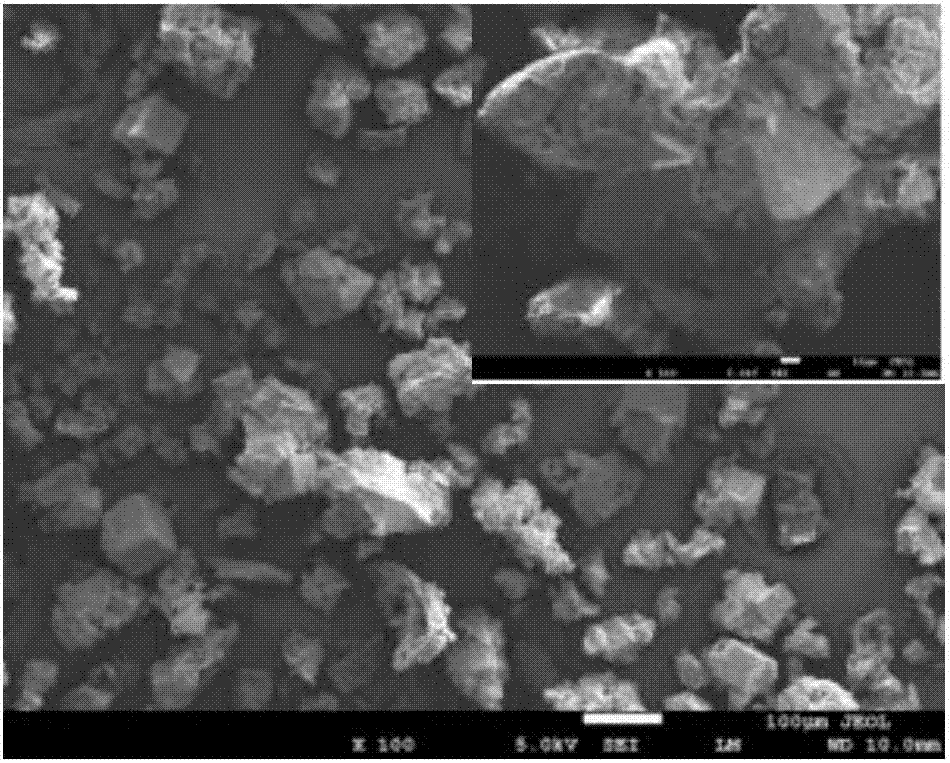

[0032] Aminated lignin A was prepared as in Example 1, wherein the reaction conditions were changed to temperature 60° C., reaction pressure 0.5 MPa, microwave power 600 W, and reaction time 10 minutes to obtain aminated lignin A (mass yield 88.9%). Take 8 g of vulcanizing agent CS2 (0.2 mol) and slowly add it to the suspension of aminated lignin A (mass concentration 10%) dissolved in pyridine solvent, wherein the molar ratio of CS2 to aminated lignin B is about 2:1.40 Stir the reaction at ℃ for 48 hours, wait for the product to cool to room temperature, filter, wash with ethanol solvent, wash with distilled water, and dry at 80℃ for 5 hours to obtain a solid substance which is a thioaminated lignin-based strong oil-absorbing material B (mass yield 89.4% ).

[0033] The commercial oil-absorbing resin materials butyl acrylate and octadecyl acrylate polymer were used as the control sample C to carry out the chloroform adsorption test experiment, and 0.1g of the above-mentioned ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com