Composite Moringa oleifera sugar polypeptide-amino acid buccal tablet and preparation method thereof

A technology of Moringa glycopolypeptide and glycopolypeptide, which is applied in the field of compound Moringa glycopolypeptide-amino acid lozenges and its preparation, can solve the problems of difficult degradation, difficult absorption, low biological potency, etc., and achieve fast absorption speed , increase the hydrolysis rate, high bioavailability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] The present invention also provides a preparation method of compound Moringa glycopolypeptide-amino acid buccal tablet, comprising the following steps:

[0038] Step 1. Prepare Moringa Proteoglycan Polypeptide-Amino Acid Liquid:

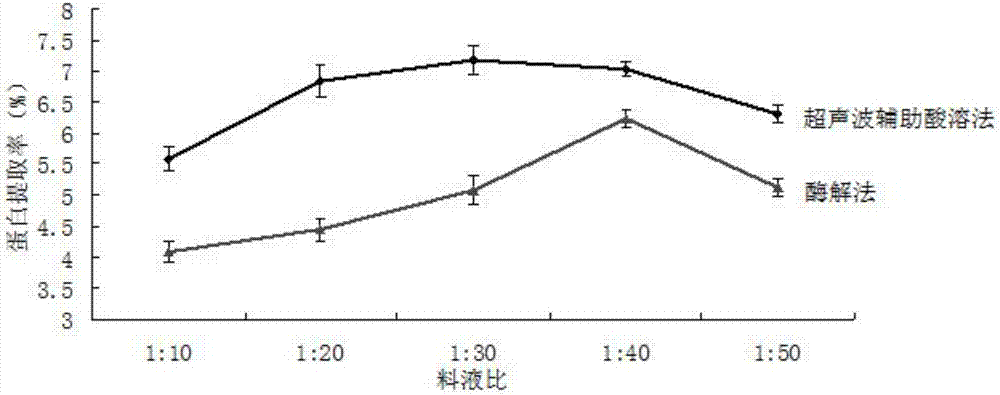

[0039] Step 1.1: Pulverize the leaves of Moringa oleifera to prepare dry powder of leaves of Moringa oleifera, homogenize the dry powder of leaves of Moringa oleifera with water at a material-to-liquid ratio of 1:10 to 1:20 g / g, and homogenize at a temperature of 50-60°C; then Add food-grade citric acid to adjust the pH to 2.0-2.5; ultrasonic-assisted extraction at a power of 250-300W for 50-60min; sodium oxide or potassium hydroxide to adjust the pH to 5.0-5.5; enzymatic hydrolysis with xylanase and glucoamylase in turn to prepare Moringa protein liquid;

[0040] Among them, the addition amount of xylanase is 7000U / g~7500U / g, the enzymatic hydrolysis temperature of xylanase is 55-60℃, and the enzymatic hydrolysis time of xylanase is 2~6h; th...

Embodiment 1

[0090] A preparation method of compound Moringa glycopolypeptide-amino acid buccal tablet, comprising the following steps: pulverizing Moringa leaves to prepare Moringa leaf dry powder, mixing Moringa leaf dry powder and water according to the material-to-liquid ratio of 1:20, at 55 Homogenize at a temperature of ℃; then add food-grade citric acid to adjust the pH to 2.2; use ultrasonic-assisted extraction for 55 minutes under the condition of a power of 250W; Adjust the pH to 5.2 with food-grade sodium hydroxide or potassium hydroxide; perform enzymatic hydrolysis with xylanase and glucoamylase in turn to prepare Moringa oleifera protein liquid; wherein, the amount of xylanase added is 7000U / g, and xylan Enzyme hydrolysis temperature is 58℃, xylanase hydrolysis time is 4h; the amount of glucoamylase added is 8000U / g, glucoamylase hydrolysis temperature is 58℃, glucoamylase hydrolysis time is 2h;

[0091] Under the condition of 18Mpa, the prepared Moringa protein liquid was ho...

Embodiment 2

[0096] A preparation method of compound Moringa glycopolypeptide-amino acid buccal tablet, comprising the following steps: pulverizing Moringa leaves to prepare Moringa leaf dry powder, mixing Moringa leaf dry powder and water according to the material-to-liquid ratio of 1:10, at 50 Homogenize at a temperature of ℃; then add food-grade citric acid to adjust the pH to 2.0; use ultrasonic-assisted extraction for 50 minutes under the condition of a power of 300W; Adjust the pH to 5.0 with food-grade sodium hydroxide or potassium hydroxide; enzymatically hydrolyze with xylanase and glucoamylase in turn to prepare Moringa oleifera protein liquid; wherein, the amount of xylanase added is 7500U / g, and xylan Enzyme hydrolysis temperature is 55℃, xylanase hydrolysis time is 6h; the amount of glucoamylase added is 9000U / g, glucoamylase hydrolysis temperature is 55℃, glucoamylase hydrolysis time is 3h;

[0097] Under the condition of 15Mpa, the prepared Moringa protein liquid was homogen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com