Highly-heatproof water-soluble alkali-developable UV photosensitive anti-etching ink

A technology with high hot water resistance and alkali development, applied in ink, optics, photography, etc., can solve the problem that water-based UV ink cannot fully meet the heat resistance requirements of lead-free technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

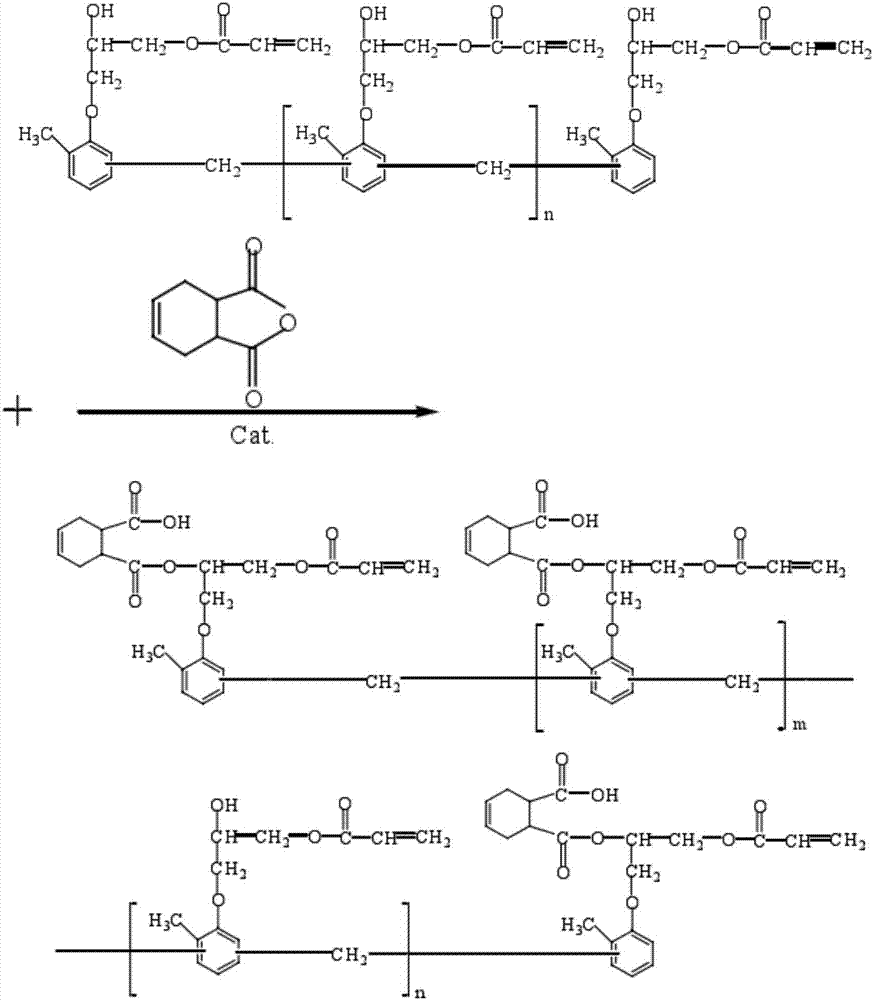

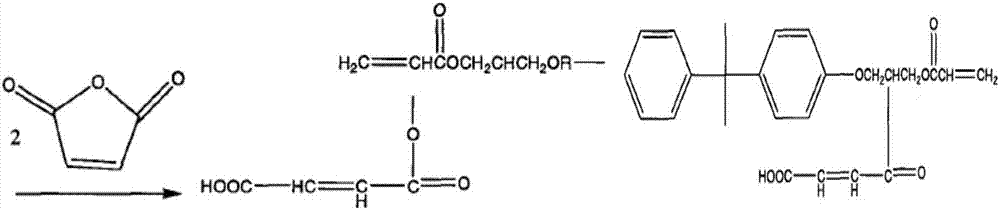

[0081] Embodiment 1: Preparation of water-soluble photo-oligomer 1

[0082] 1) Synthesis of novolac epoxy acrylate resin: 177 parts of novolac epoxy resin (manufactured by Changchun Artificial Resin, PNE-177) and 30 parts of trimethylolpropane triacrylate were heated to 83°C to dissolve, and then slowly added dropwise A mixture of 65 parts of acrylic acid, 0.3 part of catalyst triphenylphosphine, and 0.1 part of polymerization inhibitor p-hydroxyanisole was heated to 100°C for 7 hours to obtain novolac epoxy acrylate resin;

[0083] 2) Cool the novolac epoxy acrylate prepared above to 65°C, add 0.25 parts of polymerization inhibitor and 0.1 part of catalyst, stir well, add 100 parts of maleic anhydride, heat up to 78°C, and react for 2 hours.

[0084] 3) Stop the reaction when the acid value is close to the theoretical acid value, add 0.1 part of polymerization inhibitor, lower the temperature, when the temperature drops to 45°C, slowly add 10 parts of organic amine N, N-dimet...

Embodiment 2

[0085] Embodiment 2: Preparation of water-soluble photo-oligomer 2

[0086] 1) Synthesis of novolac epoxy acrylate resin: 187 parts of novolac epoxy resin (manufactured by Changchun Artificial Resin, PNE-177) and 30 parts of trimethylolpropane triacrylate were heated to 75°C to dissolve, and then slowly added dropwise A mixture of 72 parts of acrylic acid, 0.35 parts of catalyst triphenylphosphine, and 0.12 parts of polymerization inhibitor p-hydroxyanisole was heated to 105 ° C for 7 hours to obtain novolac epoxy acrylate resin;

[0087] 2) Cool the novolac epoxy acrylate prepared above to 50°C, add 0.3 parts of polymerization inhibitor and 0.15 parts of catalyst, stir well, add 140 parts of maleic anhydride, heat up to 75°C, and react for 2.5 hours.

[0088] 3) Stop the reaction when the acid value is close to the theoretical acid value, add 0.15 parts of polymerization inhibitor, lower the temperature, when the temperature drops to 40°C, slowly add 12 parts of N,N-dimethyle...

Embodiment 3

[0089] Embodiment 3: Preparation of water-soluble photo-oligomer 3

[0090] 1) Synthesis of novolac epoxy acrylate resin: 177 parts of novolac epoxy resin (manufactured by Changchun Artificial Resin, PNE-177) and 40 parts of trimethylolpropane triacrylate were heated to 80°C to dissolve, and then slowly added dropwise A mixture of 80 parts of acrylic acid, 0.4 parts of catalyst triphenylphosphine, and 0.2 parts of polymerization inhibitor p-hydroxyanisole was heated to 100°C for 8 hours to obtain novolac epoxy acrylate resin;

[0091] 2) Cool the novolac epoxy acrylate prepared above to 55°C, add 0.35 parts of polymerization inhibitor and 0.2 parts of catalyst, stir well, add 192 parts of metaphthalic anhydride, heat up to 75°C, and react for 2 hours.

[0092] 3) When the acid value is close to the theoretical acid value, stop the reaction, add 0.15 parts of polymerization inhibitor, and lower the temperature. When the temperature drops to 50°C, slowly add 12 parts of organic ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com