Process for producing hydrogen peroxide with palladium catalyst fixed-bed anthraquinone method and its lye separator

A fixed bed, anthraquinone method technology, applied in the directions of peroxide/peroxyhydrate/peroxyacid/superoxide/ozone, chemical instruments and methods, inorganic chemistry, etc. Problems such as complex process and short service life of catalyst

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

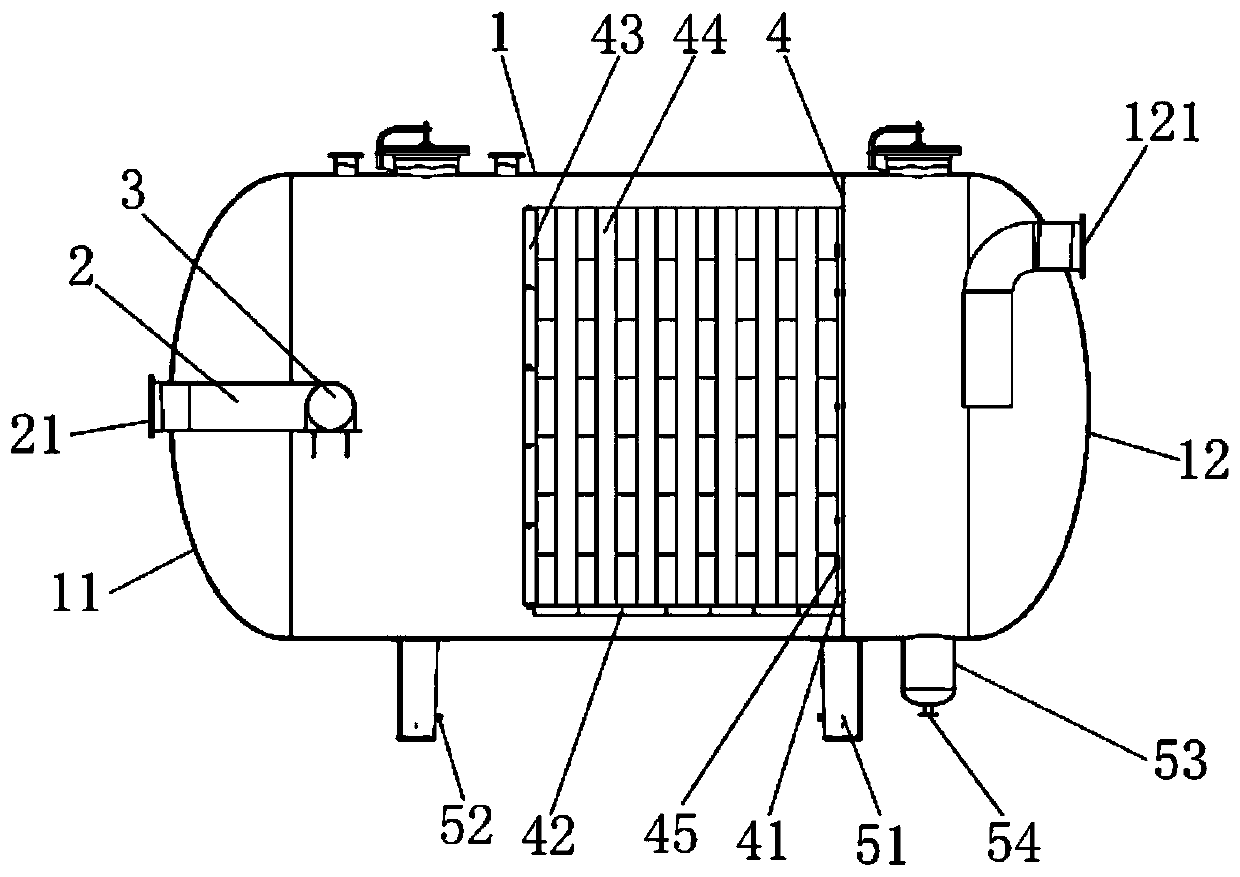

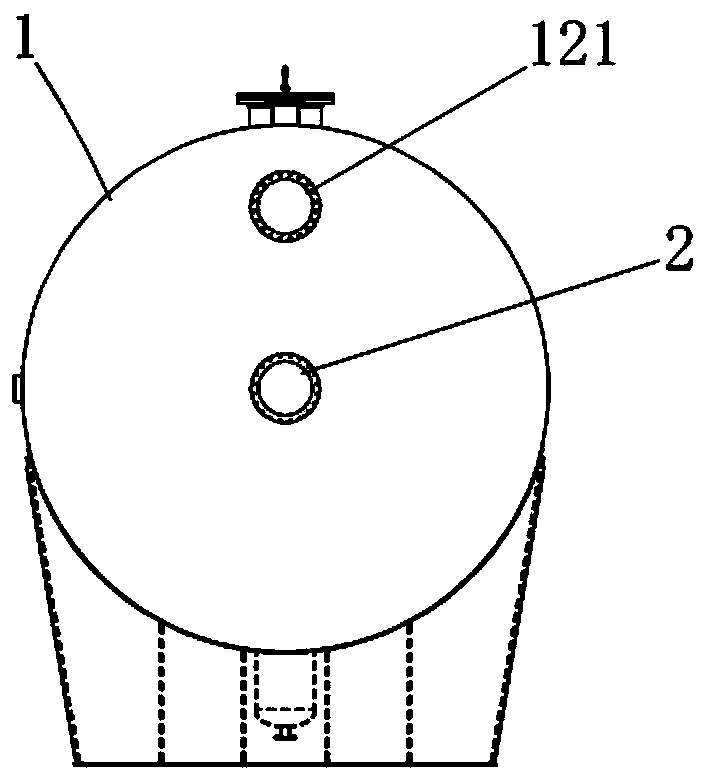

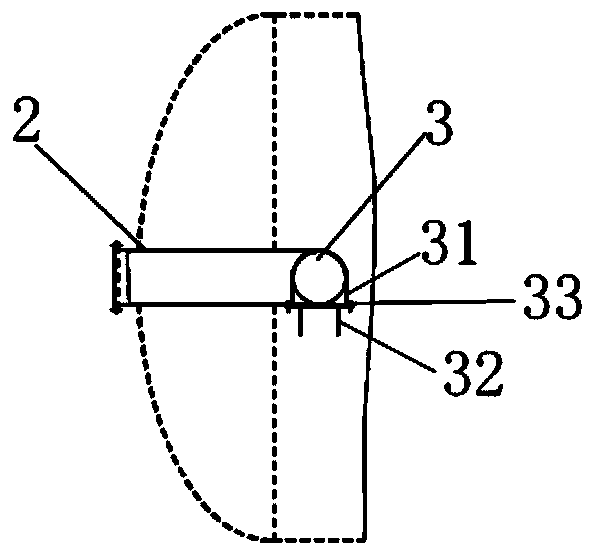

[0028] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and preferred embodiments.

[0029] Such as Figure 1-Figure 5 Shown, a kind of utilization palladium catalyst fixed-bed anthraquinone method hydrogen peroxide process of the present invention comprises the following steps:

[0030] A: Add heavy aromatics, anthraquinone and trioctyl phosphate to prepare a working liquid in a regeneration liquid storage tank; hydrogen is produced in a hydrogen extraction station and purified by a hydrogen buffer filter;

[0031] B: The working liquid from step A enters a hydrogenation tower through a regeneration liquid pump and hydrogen at the same time for catalytic reaction to obtain a hydrogenation liquid;

[0032] C: After the hydrogenation liquid from the hydrogenation tower is controlled by the automatic control instrument to set the liquid level, 10-20% is separated by the pressure in the hydrogenation t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com