Method for preparing pressure-sensitive material based on carbonized sponge

A technology of sensitive materials and sponges, applied in sensors, medical science, diagnosis, etc., can solve problems such as unfavorable industrial production and application, difficulty in obtaining raw materials, complicated preparation process, etc., and achieve sufficient raw materials, good flexibility, and simple preparation process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] ①The melamine sponge was thermally decomposed under the protection of nitrogen at a high temperature of 800°C for 1 hour to obtain carbonized sponge A. ② Connect the two ends of the carbonized sponge A prepared in step ① to the metal copper foil with conductive glue, respectively, as electrodes.

[0026] ③ Pouring 50% polydimethylsiloxane resin by volume into the carbonized sponge A connected with the copper foil electrode in step ②, vacuum degassing, and curing the resin to obtain the pressure-sensitive material.

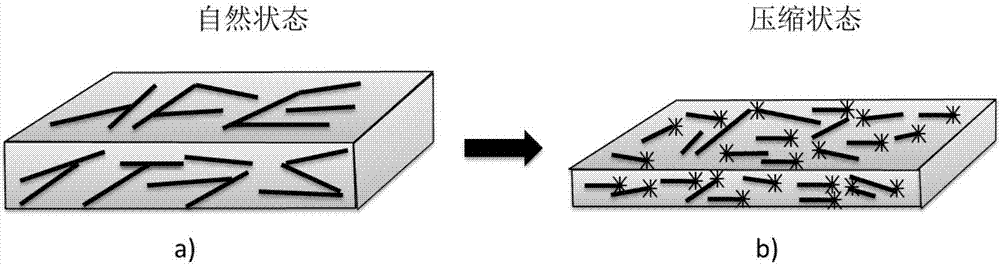

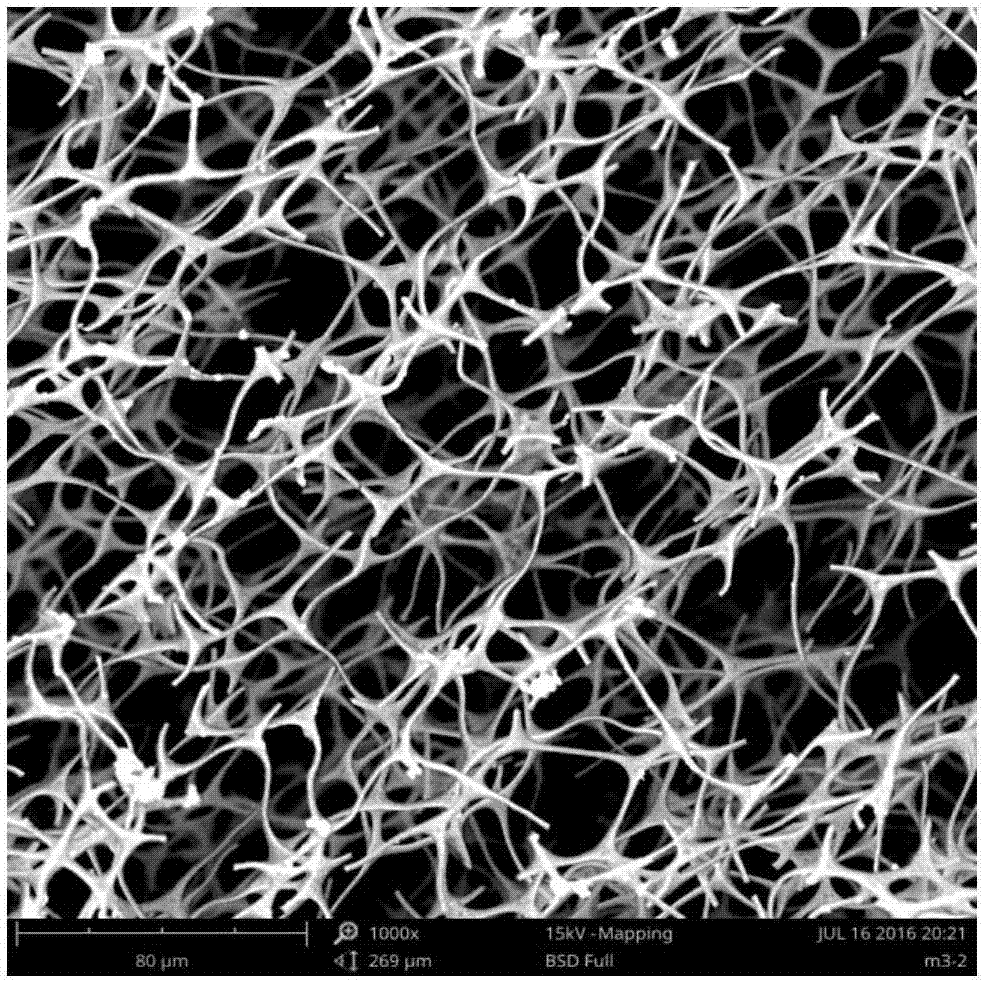

[0027] figure 1 Schematic diagram of the working principle of the carbonized sponge-based pressure-sensitive material prepared for the present invention, wherein a) represents the state of the carbonized fiber when there is no pressure; b) represents the state where the carbonized fiber of the flexible pressure-sensitive material is broken under pressure. figure 2 It is the SEM photo of the prepared carbonized sponge. It can be seen from the figure that th...

Embodiment 2

[0029] ① Under the protection of argon, thermally decompose the melamine sponge at a high temperature of 700°C for 5 hours to obtain carbonized sponge B. ② Connect the two ends of the carbonized sponge B prepared in step ① to the metal aluminum foil with conductive glue, as electrodes.

[0030] ③ Pouring 20% polydiethylsiloxane resin by volume into the carbonized sponge B connected with the aluminum foil electrode in step ②, vacuum degassing, and curing the resin to obtain the pressure-sensitive material.

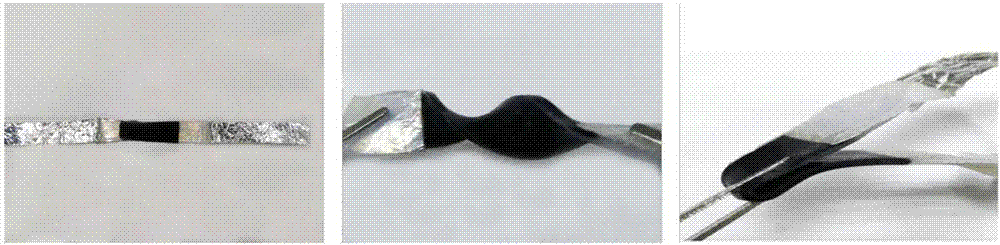

[0031] The electrical conductivity of the carbonized sponge B prepared by using the method provided by the present invention is 0.004S / m. The prepared pressure-sensitive material has good flexibility and can be bent at any angle. The pressure-sensitive material has a good response to pressure changes, and the pressure sensitivity coefficient is 16.78.

Embodiment 3

[0033] ① Under the protection of helium, thermally decompose the melamine sponge at a high temperature of 1000°C for 0.5 hours to obtain carbonized sponge C.

[0034] ② Connect the two ends of the carbonized sponge C prepared in step ① to the metal aluminum wire with conductive glue, and use it as an electrode.

[0035] ③ Pouring 100% volume polymethylvinylsiloxane resin into the carbonized sponge C connected with the aluminum wire electrode in step ②, vacuum degassing, and curing the resin to obtain the pressure sensitive material.

[0036] The electrical conductivity of the carbonized sponge C prepared by using the method provided by the present invention is 1.599 S / m. The prepared pressure-sensitive material has good flexibility and can be bent at any angle. The pressure-sensitive material has a good response to pressure changes, and the pressure sensitivity coefficient is 12.20.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com