Method for preparing large-area photonic crystals

A photonic crystal, large-area technology, applied in optics, optical components, instruments, etc., can solve the problems of limited photonic crystals, low production efficiency, complex equipment, etc., and achieve the effect of large area, simple device, and low production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

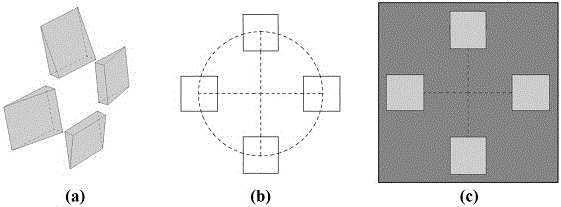

[0027] In this embodiment, taking a three-wedge mirror plate inlaid with three wedge-shaped prisms as an example, a large-area two-dimensional triangular lattice photonic crystal is produced, and the specific method is as follows:

[0028] (1) Mount three wedge-shaped prisms with a size of 18mm×18mm and a wedge angle of 3.5° on the plate. The bottom edge of the wedge-shaped prism faces the center of the plate. The prisms are all deflected toward the normal direction of the flat center, and the deflection angle of the light beam is determined by the wedge angle of the wedge prism to make a polygonal mirror plate 3;

[0029] (2) The laser beam emitted by the laser 1 is expanded by the beam expander 2, and the expanded light is irradiated onto the polygonal mirror plate 3 made in step (1), and the beam passes through the polygonal mirror plate When the wedge prism propagates, it will be deflected towards the bottom edge of the wedge prism, and still maintain the state of plane wa...

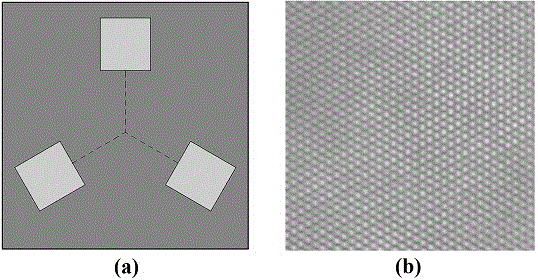

Embodiment 2

[0033] In this embodiment, four inlaid wedge prisms are set, the size of the wedge mirror is 15mm×15mm, and the wedge angle is 3.3°, as image 3 Shown in a. All the other preparation methods are the same as in Example 1, and the area of the two-dimensional tetragonal lattice photonic crystal produced in the photorefractive crystal is about 200mm 2 . Such as image 3 As shown in b, the present embodiment utilizes a two-dimensional tetragonal lattice photonic crystal made of a four-wedge mirror plate.

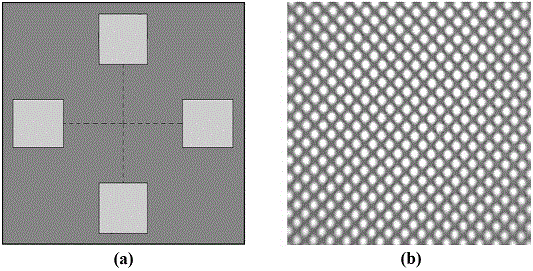

Embodiment 3

[0035] In this embodiment, five inlaid wedge prisms are set, the size of the wedge mirror is 12mm×12mm, and the wedge angle is 3°, as Figure 4 Shown in a. The rest of the preparation method is the same as in Example 1, and the area of the two-dimensional photonic quasicrystal structure produced in the photorefractive crystal is about 100mm 2 . Such as Figure 4 As shown in b, in this embodiment, a two-dimensional photonic quasicrystal structure made of a five-wedge mirror plate is used.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com