Innovation method of anodized negative plate

An anodic oxidation, anodic oxidation tank technology, applied in the direction of anodic oxidation, electrodes, electrolytic coatings, etc., can solve the problems of uneven oxide film thickness and performance, increase the area of the cathode plate, etc., achieve the reduction of bubbles and impurities, prolong life, prevent The effect of failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

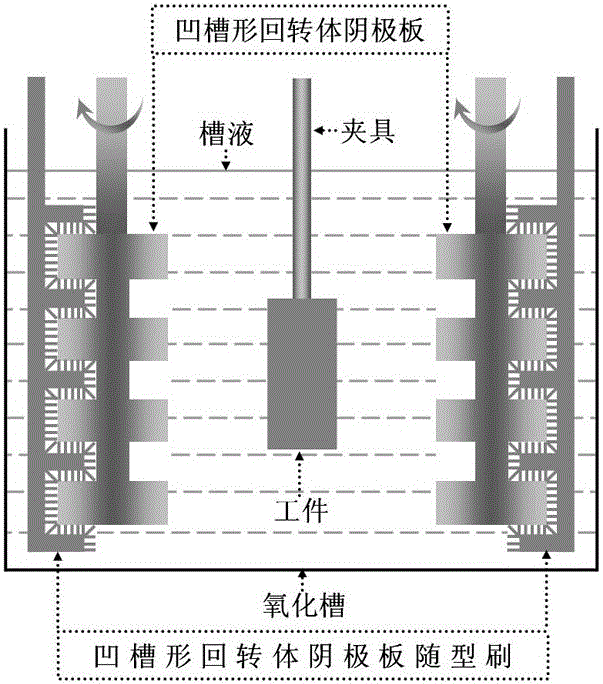

[0017] Example 1: The work of anodizing the negative plate of the groove-shaped rotary body.

[0018] First, the aluminum cathode material is made into a groove-shaped rotary cathode plate, and the cathode plate is installed on the inner side of the oxidation tank; and the cathode plate is made of PTFE with brush bristles, which are attached to the outer surface of the cathode plate; then the workpiece is clamped for Anodizing, the cathode plate rotates stably in the bath at a speed of 1r / min (such as figure 1 shown); after anodizing, stop the rotation of the cathode plate, remove and clean the workpiece.

Embodiment 2

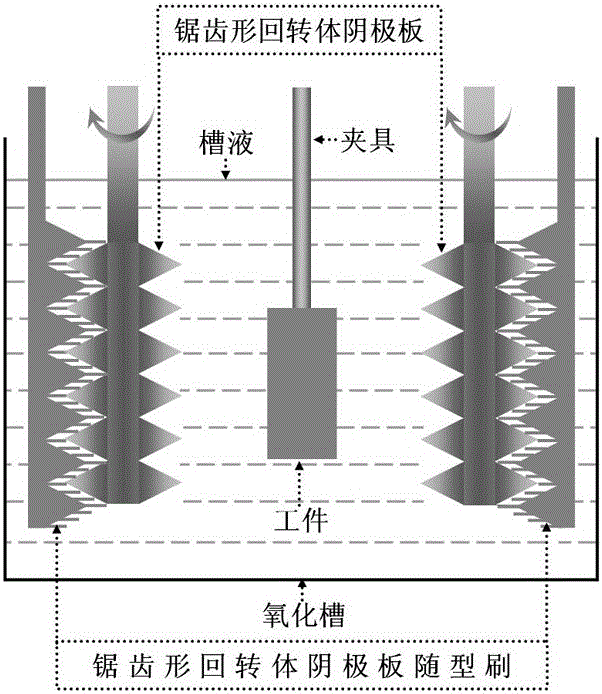

[0019] Example 2: The work of anodizing the cathode plate of the zigzag rotor.

[0020] First, the lead cathode material is made into a zigzag rotary cathode plate, and the cathode plate is installed on the inner side of the oxidation tank; and the carbon fiber is used to make the brush bristles of the cathode plate, which are attached to the outer surface of the cathode plate; then the workpiece is clamped for anode Oxidation, the cathode plate rotates stably in the bath at a speed of 12r / min (such as figure 2 shown); after anodizing, stop the rotation of the cathode plate, remove and clean the workpiece.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com