Liquor steaming equipment

A kind of wine steaming equipment and technology of wine grains, which is applied in the preparation of alcoholic beverages, etc., can solve the problems of mixing and affecting the quality of wine, and achieve the effects of reducing the temperature of wine, accelerating the speed of steaming, and increasing the rate of wine production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

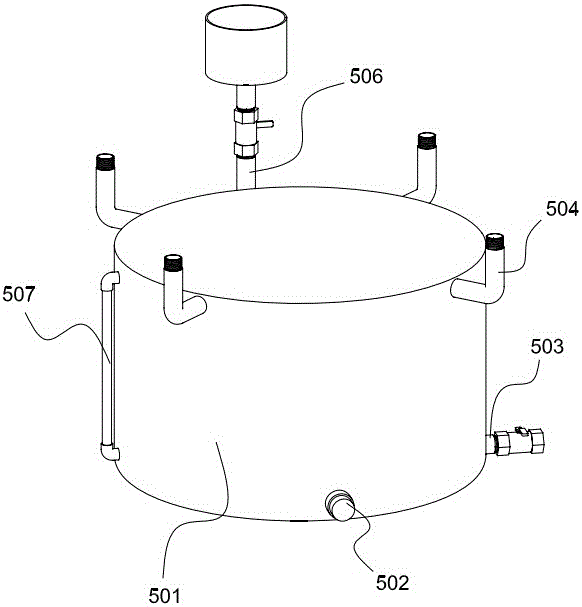

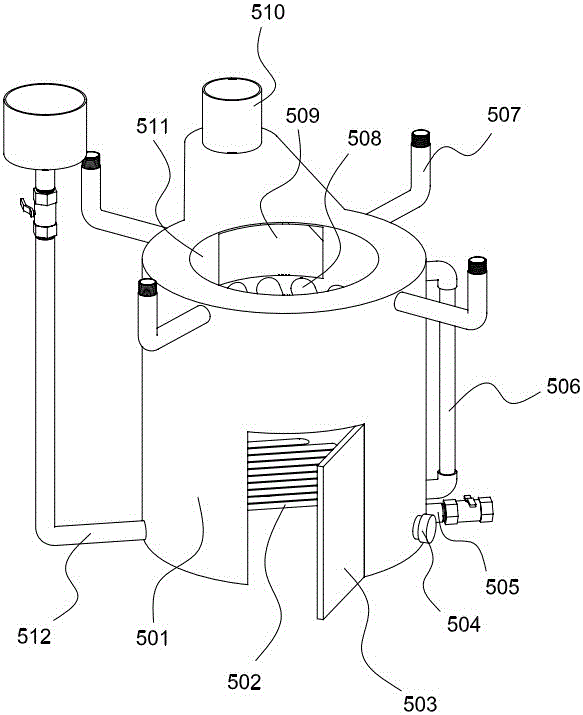

[0083] This embodiment includes the above-mentioned third steam generator ( image 3 shown), the first type of distillation barrel ( Figure 9 shown), the first distillation cap ( Figure 13 shown), the first wine vapor tube and condenser ( Figure 16 shown), also includes a blower, the air outlet of the blower is welded to one end of a metal pipe, and the other end of the metal pipe is connected to image 3 The upper end of the "L" shaped air duct 502 of the shown steam generator 501 is threaded. This embodiment also includes a rubber tube, which is the second air guide tube, one end of which is connected with the air inlet of the blower, and the other end is connected with the air outlet pipe of the condenser. The first type of distillation barrel and the first type of distillation cover together constitute the still for holding fermented grains in the technical solution part.

Embodiment 2

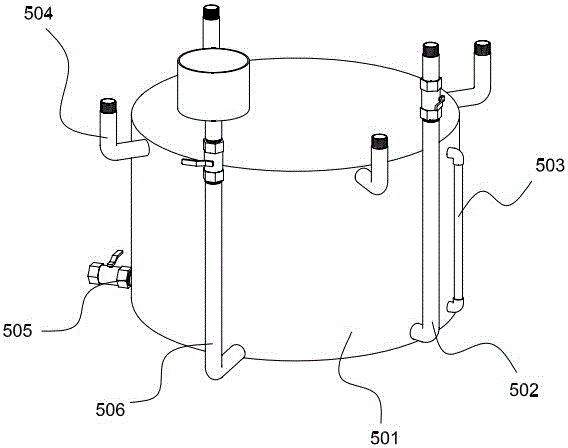

[0085] This embodiment includes the above-mentioned first steam generator ( figure 1 shown), the second type of distillation barrel ( Figure 10 shown), the first distillation cap ( Figure 13 shown), the second wine vapor tube and condenser ( Figure 17 shown), also includes a blower, the air outlet of the blower is welded to one end of a metal pipe, and the other end of the metal pipe is connected to Figure 10 The upper end of the "L" shaped air guide pipe 404 on the shown distillation barrel 400 is threadedly connected. This embodiment also includes a rubber tube, which is the second air guide tube, one end of which is connected with the air inlet of the blower, and the other end is connected with the air outlet pipe of the condenser. The second kind of distillation barrel and the first kind of distillation cover jointly constitute the still of the described wine grains in the technical solution part

Embodiment 3

[0087] This embodiment includes the above-mentioned second steam generator ( figure 2 shown), the third type of distillation barrel ( Figure 11 shown), the first distillation cap ( Figure 13 shown), the first wine vapor tube and condenser ( Figure 16 shown), also includes a blower, the air outlet of the blower is welded to one end of a metal pipe, and the other end of the metal pipe is connected to Figure 11 The horizontal straight pipe 405 on the distillation barrel 400 shown is threaded. This embodiment also includes a rubber tube, which is the second air guide tube, one end of which is connected with the air inlet of the blower, and the other end is connected with the air outlet pipe of the condenser. The third type of distillation barrel and the first type of distillation cover together constitute the still for holding fermented grains in the technical solution part.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com