High-solid epoxy-terminated polyurethane resin for synthetic leather and preparation method thereof

A polyurethane resin, epoxy end-capping technology, used in textiles and papermaking, etc., can solve the problems of sealant release and residual environmental hazards, environmental and occupational health hazards, and achieve good storage and transportation stability and environmental protection performance. , the effect of excellent physical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

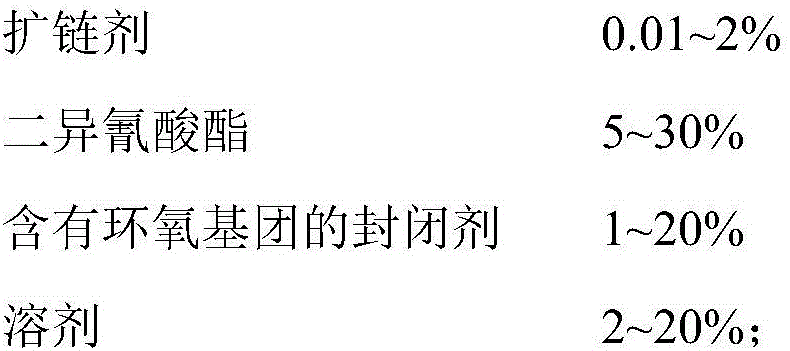

[0037] The raw materials and quality used in this embodiment are shown in Table 1.

[0038] Table 1

[0039]

[0040] The preparation steps of high solid epoxy-terminated polyurethane resin for synthetic leather of the present embodiment are as follows:

[0041] (1) The weighed polypropylene oxide ether diol (number average molecular weight 4000), polybutylene adipate diol (number average molecular weight 2000), 1,4-butanediol and γ-caprolactone Put it into the reaction kettle, heat up to 40°C, and stir evenly;

[0042] (2) Put the weighed diphenylmethane diisocyanate into the reactor, heat up to 75°C, and detect the NCO% content after reacting at this temperature for 6 hours until the NCO% content reaches the theoretical value (NCO% theoretical value is 1.06%);

[0043] (3) Cool down to 60°C, put in the weighed glycidol, heat up to 60°C and react for 1 hour to obtain high-solid epoxy-terminated polyurethane resin for synthetic leather.

Embodiment 2

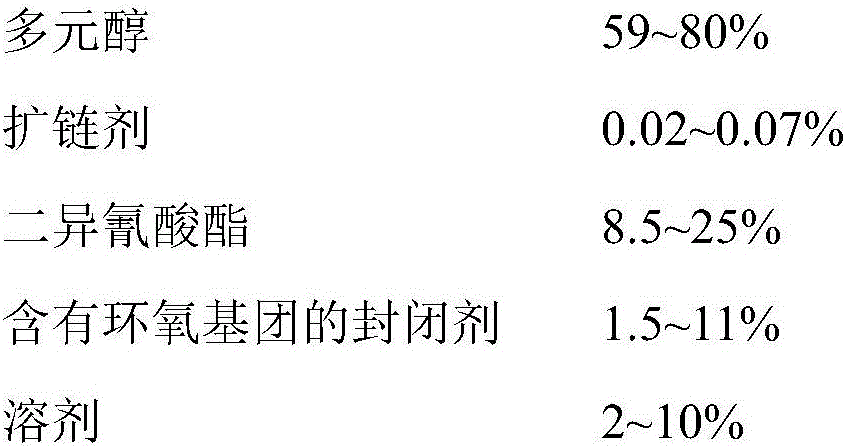

[0045] The raw materials and quality used in this embodiment are shown in Table 2.

[0046] Table 2

[0047]

[0048]

[0049] The preparation steps of high solid epoxy-terminated polyurethane resin for synthetic leather of the present embodiment are as follows:

[0050] (1) Polypropylene oxide ether diol (number-average molecular weight 6000), polyneopentyl adipate diol (number-average molecular weight 1000), neopentyl glycol and 1,2-butene carbonate Put the ester into the reaction kettle, heat up to 40°C, and stir evenly;

[0051] (2) Put the weighed diphenylmethane diisocyanate into the reactor, heat up to 75°C, and detect the NCO% content after reacting at this temperature for 6 hours until the NCO% content reaches the theoretical value (NCO% theoretical value is 2.54%);

[0052] (3) Cool down to 60° C., put in weighed glycidol, heat up to 70° C. and react for 1 hour to obtain a high-solid epoxy-terminated polyurethane resin for synthetic leather.

Embodiment 3

[0054] The raw materials and quality used in this embodiment are shown in Table 3.

[0055] table 3

[0056]

[0057] The preparation steps of high solid epoxy-terminated polyurethane resin for synthetic leather of the present embodiment are as follows:

[0058] (1) The weighed polypropylene oxide ether diol (number average molecular weight 6000), polymethylpropylene adipate diol (number average molecular weight 1000), 2-methyl-1,3-propanediol and carbonic acid Put the vinyl ester into the reaction kettle, raise the temperature to 30°C, and stir evenly;

[0059] (2) Put the weighed toluene diisocyanate and diphenylmethane diisocyanate into the reactor, heat up to 70°C, and detect the NCO% content after reacting at this temperature for 6 hours until the NCO% content reaches the theoretical value (NCO % theoretical value is 3.45%);

[0060] (3) Cool down to 50° C., put in weighed glycidol, heat up to 60° C. and react for 1 hour to obtain a high-solid epoxy-terminated polyure...

PUM

| Property | Measurement | Unit |

|---|---|---|

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com