Multifunctional liquid medicine fertilizer and preparation method and application thereof

A liquid medicine, multi-functional technology, applied in the direction of liquid fertilizer, application, nitrogen fertilizer, etc., can solve the problems of unsatisfactory effect, neglect of pest prevention, large dosage of medicine, etc., to improve the safety of medicine, good prevention and killing effect , the effect of improving the survival rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

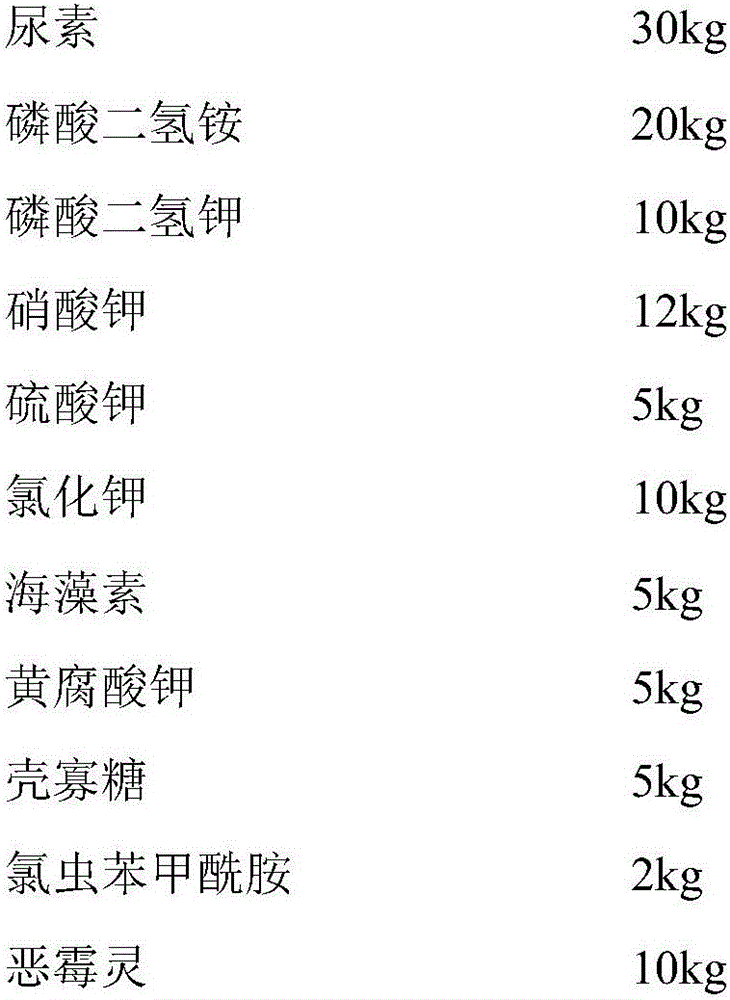

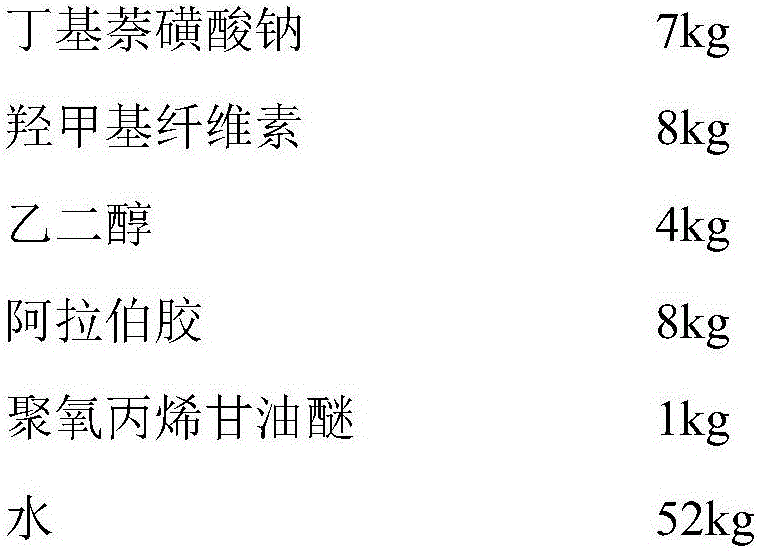

Embodiment 1

[0028]

[0029]

[0030] The preparation method is as follows:

[0031] (1) Prepare the above raw materials according to the formula;

[0032] (2) 7 kg of sodium butylnaphthalene sulfonate, 8 kg of hydroxymethyl cellulose, 8 kg of gum arabic, 1 kg of polyoxypropylene glyceryl ether, 10 kg of hymexazol, and 2 kg of chlorantraniliprole were pretreated using a ball mill and then transferred to a supernatant. Grind with a micro pulverizer (up to 3000 meshes), then add it to a high-speed mixer filled with 52kg of water, and stir at a constant speed of 1500r / min for 20-30 minutes to make the agent evenly distributed;

[0033] (3) Add 5 kg of alginate and 5 kg of chitosan oligosaccharide into a high-speed mixer, keep the temperature at 20° C., and stir at a constant speed of 1500 r / min for 10 minutes;

[0034] (4) Add 5kg of potassium fulvic acid and 4kg of ethylene glycol into a high-speed mixer, keep the temperature at 20°C, and stir at a constant speed of 1500r / min for 20 m...

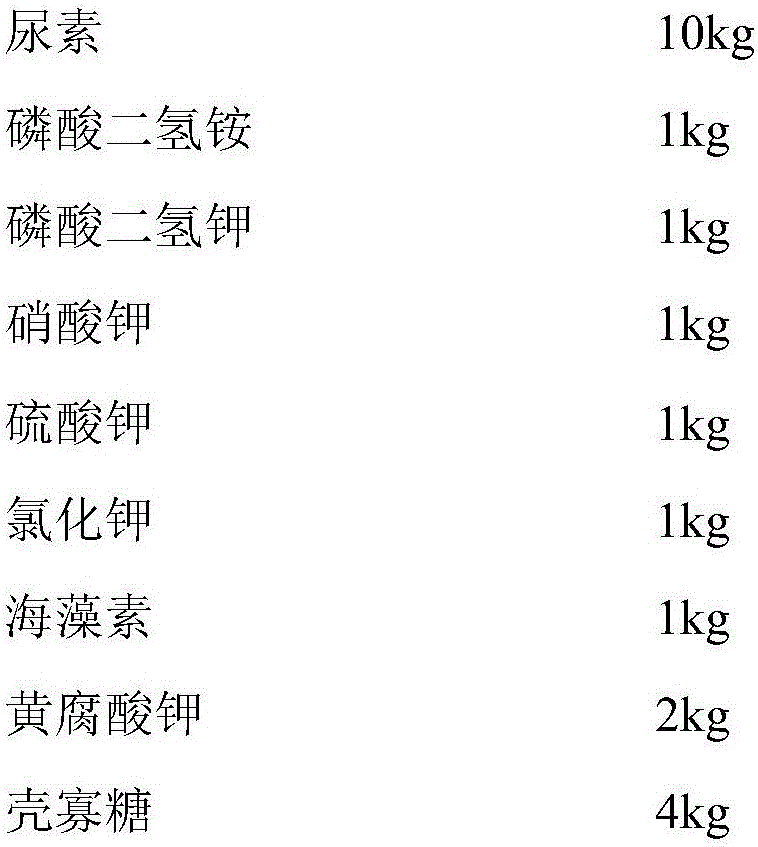

Embodiment 2

[0038]

[0039]

[0040] The preparation method is as follows:

[0041] (1) Prepare the above raw materials according to the formula;

[0042] (2) 1kg of sodium butylnaphthalene sulfonate, 8kg of hydrogenated glyceryl palmitate, 3kg of polyoxypropylene glyceryl ether, 10kg of hymexazol, and 4kg of chlorantraniliprole were pretreated with a ball mill and then transferred to an ultrafine pulverizer Grinding treatment (up to 3000 mesh), then adding to a high-speed mixer filled with 90kg of water, stirring at a constant speed of 1500r / min for 30 minutes, so that the medicament is evenly distributed;

[0043] (3) Add 1kg of seaweed and 4kg of chitosan oligosaccharide into a high-speed mixer, keep the temperature at 40°C, and stir at a constant speed of 1500r / min for 20 minutes;

[0044] (4) Add 2kg of potassium fulvic acid and 2kg of polyethylene glycol into a high-speed mixer, maintain the temperature at 40°C, and stir at a constant speed of 1500r / min for 30 minutes;

[00...

Embodiment 3

[0048]

[0049]

[0050] The preparation method is as follows:

[0051] (1) Prepare the above raw materials according to the formula;

[0052] (2) Use 5kg of sodium lauryl sulfate, 2kg of dioctyl sodium sulfosuccinate, 3kg of polyoxypropylene glyceryl ether, 1kg of hydroxymethylcellulose, 1.5kg of hymexazol, and 1.5kg of chlorantraniliprole After the ball mill is pretreated, it is transferred to an ultrafine pulverizer for grinding (up to 3000 mesh), and then added to a high-speed mixer filled with 75kg of water, and stirred at a constant speed of 1500r / min for 25 minutes to make the medicament evenly distributed;

[0053] (3) Add 3 kg of seaweed and 3 kg of chitosan oligosaccharides into a high-speed mixer, maintain the temperature at 20-40 ° C, and stir at a constant speed of 1500 r / min for 15 minutes;

[0054] (4) Add 3 kg of potassium fulvic acid and 1 kg of glycerin into a high-speed mixer, maintain the temperature at 20-40 ° C, and stir at a constant speed of 1500...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com