PVA (polyvinyl alcohol) fiber reinforced superhigh-toughness polymer-based composite material and preparation method thereof

A technology of ultra-high toughness and geopolymers, applied in the field of materials science, can solve the problems of poor ability to control cracks, low tensile strength of concrete, self-heaviness, etc., and achieve the effect of making up for poor ductility, low cost, and price reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

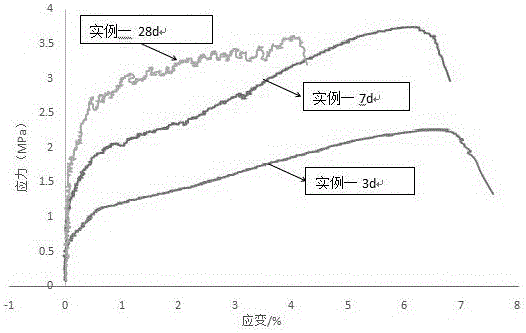

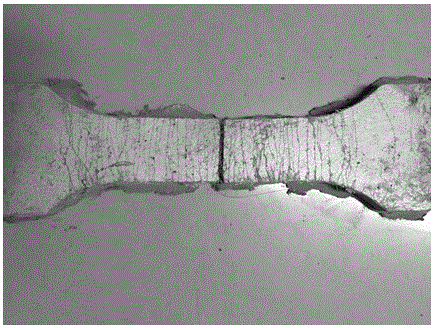

Embodiment 1

[0037] Low calcium fly ash: 542 parts, high calcium fly ash: 136 parts, quartz sand: 182.7 parts, sodium silicate: 173 parts, sodium hydroxide: 38 parts, water: 160 parts, fiber: 14 parts, metakaolin : 20.3 parts.

[0038] The mixing ratio uses first-grade high-calcium fly ash, first-grade low-calcium fly ash and metakaolin from Inner Mongolia, and the solid mixture is added to the stirring pot at a slow speed (revolution 62±5 r / min, rotation 140±5 r / min) dry stirring for 3 minutes until uniform. Then dissolve the prepared alkali activator in water and add it to the stirring pot, stir quickly (revolution 125±10 r / min, rotation 285±10 r / min) for 5 minutes, add the fiber in the stated proportion, and stir for another 6 minutes until The polyvinyl alcohol fibers are evenly dispersed, that is, the PVA-reinforced ultra-high toughness geopolymer-based composite material slurry is obtained, and finally the slurry is placed in a mold for molding, cured in an oven at 80°C for 2 hours...

Embodiment 2

[0042] Low calcium fly ash: 542 parts, high calcium fly ash: 136 parts, quartz sand: 203 parts, sodium silicate: 173 parts, sodium hydroxide: 38 parts, water: 160 parts, fiber: 15.6 parts, metakaolin : 0 copies.

[0043] The mixing ratio uses first-grade high-calcium fly ash and first-grade low-calcium fly ash. Add the solid mixture into the stirring pot, and dry stir at a slow speed (revolution 62±5 r / min, rotation 140±5 r / min) 3 minutes until smooth. Then dissolve the prepared alkali activator in water and add it to the stirring pot, stir quickly (revolution 125±10 r / min, rotation 285±10 r / min) for 5 minutes, add the fiber in the stated proportion, and stir for another 6 minutes until The polyvinyl alcohol fibers are evenly dispersed, that is, the PVA-reinforced ultra-high toughness geopolymer-based composite material slurry is obtained, and finally the slurry is placed in a mold for molding, cured in an oven at 80°C for 2 hours, and then cured at room temperature for moldi...

Embodiment 3

[0047] Low calcium fly ash: 542 parts, high calcium fly ash: 136 parts, quartz sand: 192.9 parts, sodium silicate: 173 parts, sodium hydroxide: 38 parts, water: 160 parts, fiber: 17 parts, metakaolin : 10.2 parts.

[0048] The mixing ratio uses first-grade high-calcium fly ash, first-grade low-calcium fly ash and metakaolin from Inner Mongolia, and the solid mixture is added to the stirring pot at a slow speed (revolution 62±5 r / min, rotation 140±5 r / min) dry stirring for 3 minutes until uniform. Then dissolve the prepared alkali activator in water and add it to the stirring pot, stir quickly (revolution 125±10 r / min, rotation 285±10 r / min) for 5 minutes, add the fiber in the stated proportion, and stir for another 6 minutes until The polyvinyl alcohol fibers are evenly dispersed, that is, the PVA-reinforced ultra-high-toughness polymer-based composite material slurry is obtained, and finally the slurry is placed in a mold for molding, cured in an oven at 80°C for 2 hours, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com