Saw web spindle box assembly and mining boulder strip machine

A spindle box and saw blade technology, applied in stone processing tools, stone processing equipment, work accessories, etc., can solve the problems of cumbersome saw blade replacement, affecting the quality of cutting strip stones, inaccurate assembly positioning, etc., to improve work efficiency and Production efficiency, enhance the accuracy of alignment and assembly, and ensure the effect of cutting performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

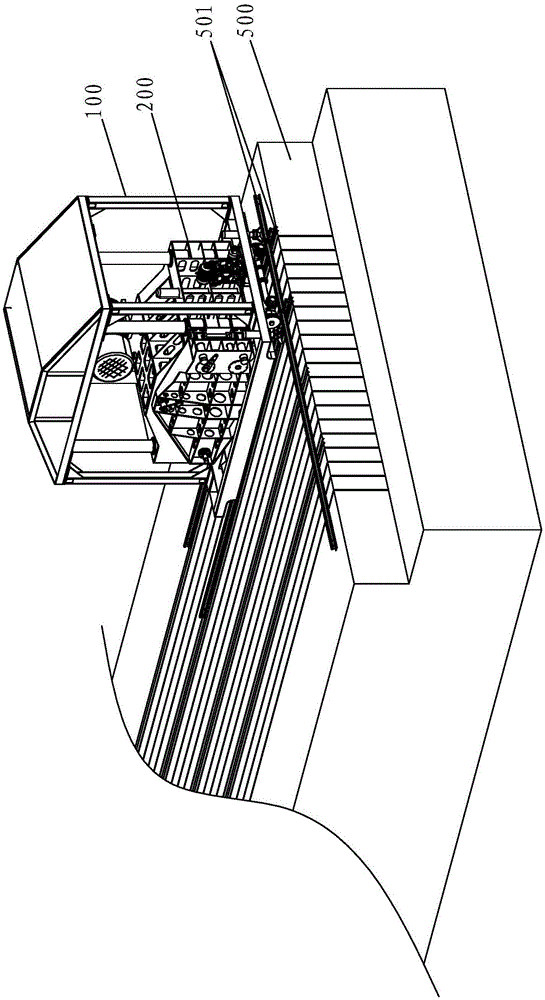

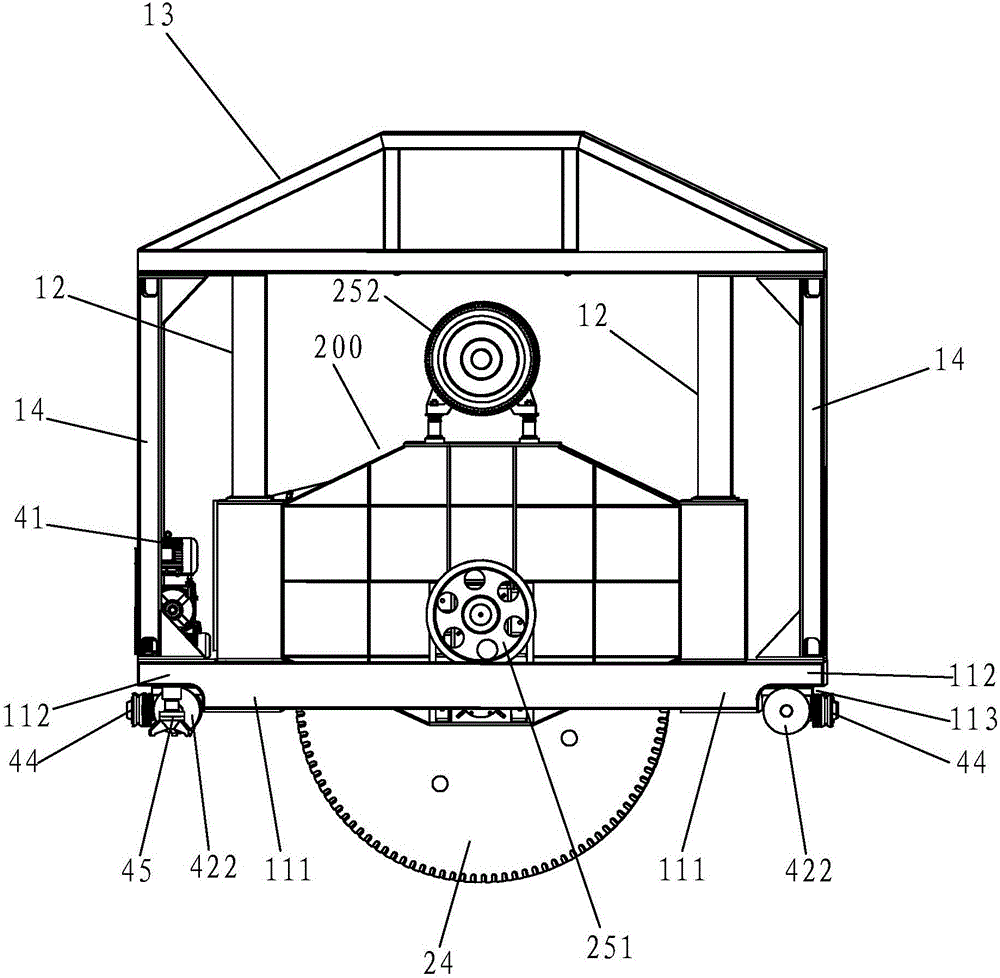

[0077] The present case will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0078] This case involves a saw blade headstock assembly 200, such as Figure 4 to Figure 7 As shown, it includes a box body 21, a box cover 22 and a main shaft 23. The box cover 22 is movably locked on the box body 21 . In a preferred embodiment, the box cover 22 is movable and installed on the box body 21 in a manner of horizontally shifting and turning relative to the box body 21 . The box body 21 has a box side wall 211 that is arranged opposite to the box cover 22, that is, when the box cover 22 is closed on the box body 21, the box cover 22 and the box side wall 211 are relatively arranged, and the box cover 22 is equivalent to the case. The movable box side wall structure of body 21.

[0079] The main shaft 23 is a shaft structure for carrying saw blades, on which several saw blades 24 are arranged side by side. The main shaft 23...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com