Compound reinforcement method for gear surface

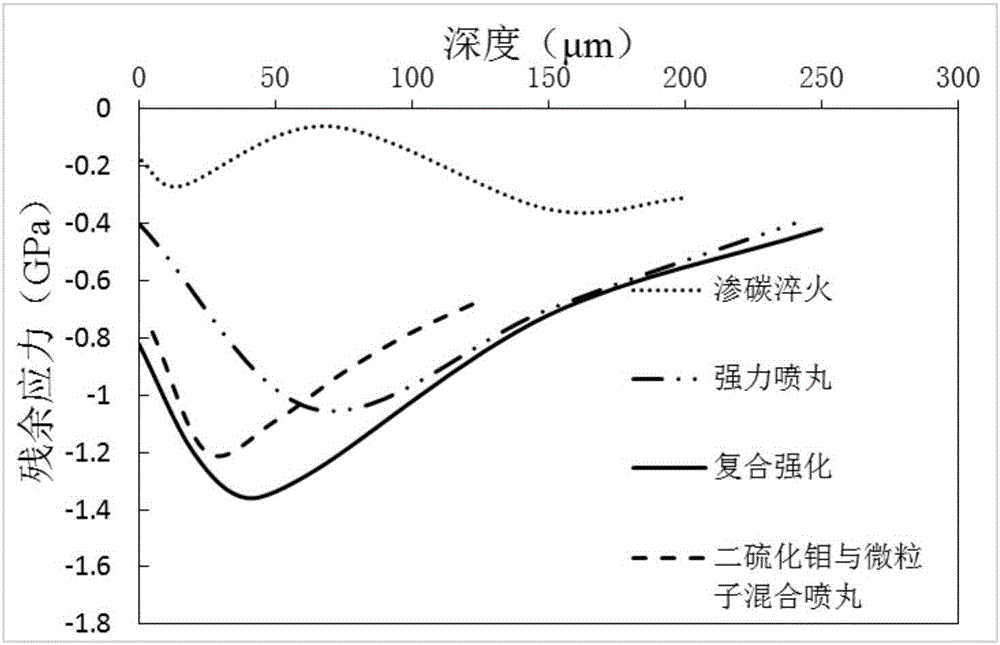

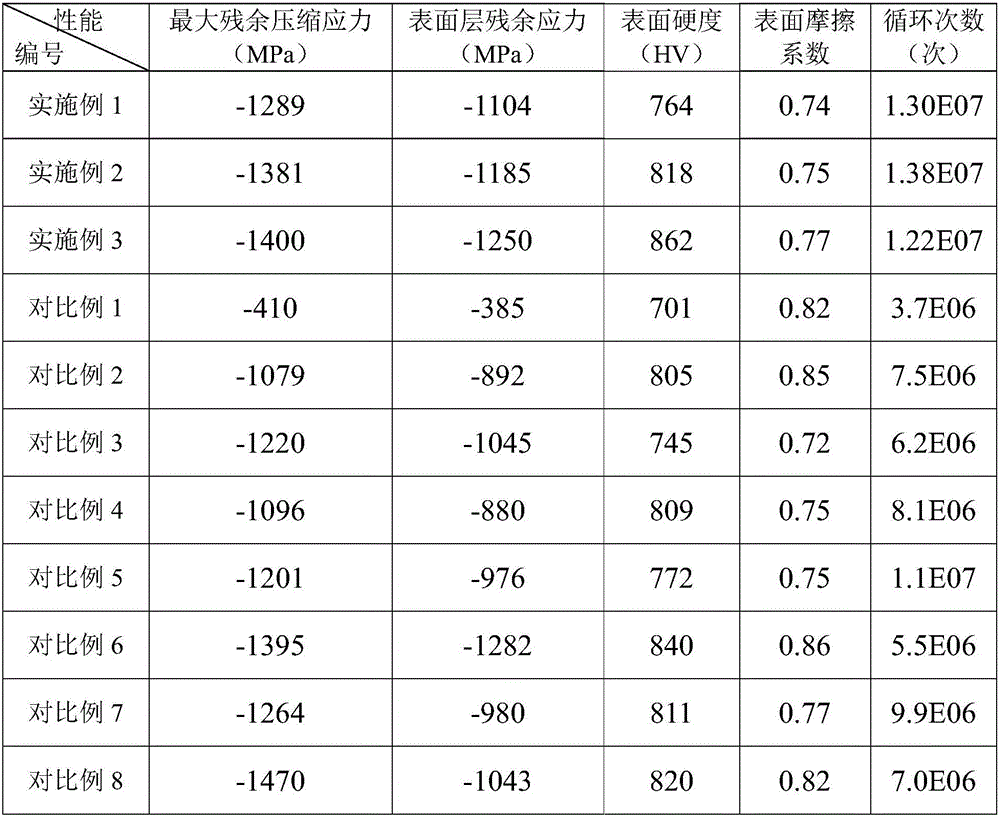

A surface composite and gear technology, which is applied in the direction of abrasives, metal processing equipment, abrasive jet machine tools, etc., can solve the problems of limited improvement of gear residual compressive stress and surface hardness, inability to effectively improve material fatigue strength, and large molybdenum disulfide particles. , to achieve the effect of improving lubricating ability and surface finish, improving contact fatigue life and anti-wear ability, reducing roughness and friction coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] (1) Use steel shots with a particle size of 0.6mm to carry out shot peening on low-carbon alloy steel gears for 95s under a pressure of 3.5Mpa;

[0041] (2) Put 0.05mm steel shot in the shot blasting material bin, heat it to 50°C, then add molybdenum disulfide 15 times its mass and mix thoroughly;

[0042] (3) Spray nitrogen cooled to 0°C onto the gear surface after shot peening in step (1), and then pass uncooled nitrogen into the shot peening material bin to push the mixture of steel shot and molybdenum disulfide against the gear surface Carry out shot peening treatment, the strength of shot peening is 0.3MPa, and the shot peening time is 50s. After the shot peening is finished, the gear with composite strengthened surface is obtained;

[0043] (4) Recover the steel shot that falls off from the gear surface after the shot peening in step (3) to the shot peening material bin for continued use.

Embodiment 2

[0045] (1) Use a steel shot with a particle size of 0.8mm, and carry out shot peening on the low-carbon alloy steel gear for 90s under a pressure of 4Mpa;

[0046] (2) Put 0.08mm steel shot in the shot blasting material bin, heat it to 180°C, then add molybdenum disulfide 20 times its mass and mix thoroughly;

[0047] (3) Spray nitrogen cooled to 0°C onto the gear surface after shot peening in step (1), and then pass uncooled nitrogen into the shot peening material bin to push the mixture of steel shot and molybdenum disulfide against the gear surface Carry out shot peening treatment, the strength of shot peening is 0.5MPa, and the time of shot peening is 40s. After the shot peening is finished, the gear with composite strengthened surface is obtained;

[0048] (4) Recover the steel shot that falls off from the gear surface after the shot peening in step (3) to the shot peening material bin for continued use.

Embodiment 3

[0050] (1) Use a steel shot with a particle diameter of 1mm to carry out shot peening for 85s to the low carbon alloy steel gear under a pressure of 4.5Mpa;

[0051] (2) Put 0.1mm steel shot in the shot blasting material bin, heat it to 300°C, then add molybdenum disulfide 25 times its mass and mix thoroughly;

[0052] (3) Spray nitrogen cooled to 0°C onto the gear surface after shot peening in step (1), and then pass uncooled nitrogen into the shot peening material bin to push the mixture of steel shot and molybdenum disulfide against the gear surface Carry out shot peening treatment, the strength of shot peening is 0.6MPa, and the shot peening time is 30s. After the shot peening is finished, the gear with composite strengthened surface is obtained;

[0053] (4) Recover the steel shot that falls off from the gear surface after the shot peening in step (3) to the shot peening material bin for continued use.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com