Composite material surface coating laser cleaner and cleaning method thereof

A technology of surface coating and laser cleaning, which is applied in the direction of cleaning methods and appliances, chemical instruments and methods, etc., can solve the problems of low paint removal efficiency, uneven coating removal, and environmental pollution on the surface of composite materials, and achieve pollution The effects of less waste, high removal efficiency, and avoidance of environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

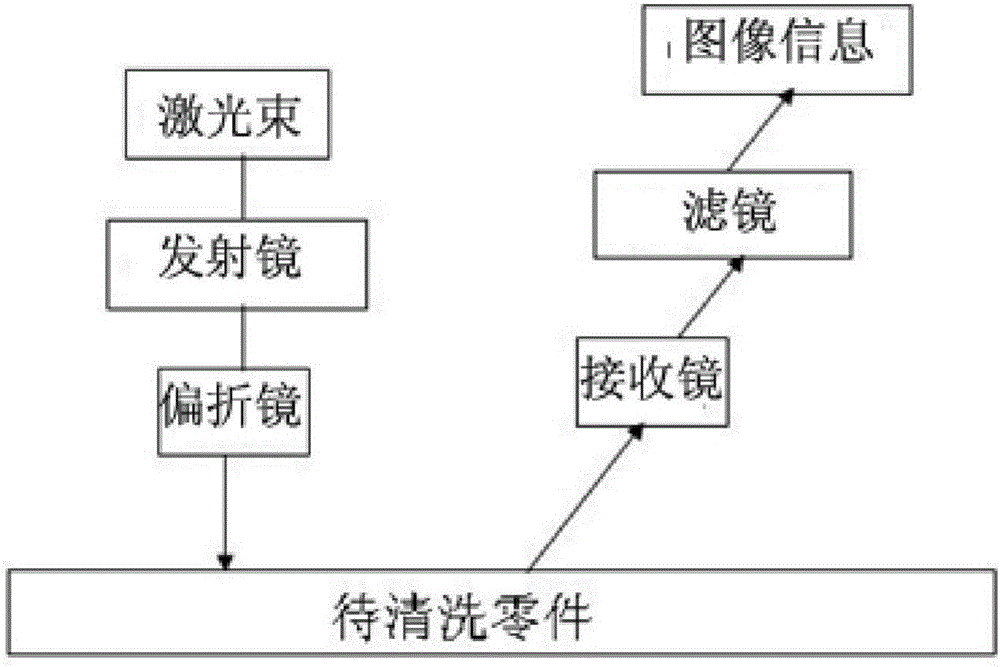

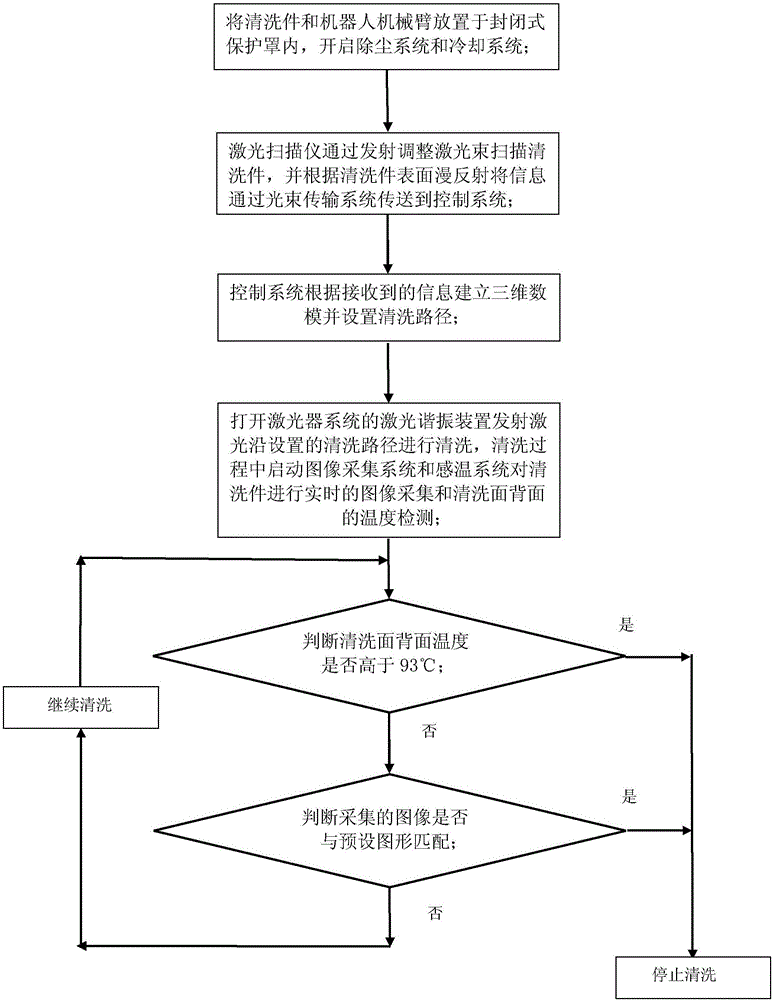

[0029] see figure 1 As shown, a kind of composite material surface coating laser cleaning device provided in this embodiment includes a control system, a beam transmission system and a laser system arranged on a robot instrument arm, a laser scanner and an image acquisition system; the laser scanner transmits Adjust the laser beam to scan the cleaning parts, and transmit the information to the control system through the beam transmission system according to the surface diffuse reflection of the cleaning parts; the control system establishes a three-dimensional digital model and sets the cleaning path according to the received information, and the laser system performs cleaning on the cleaning parts according to the cleaning path. Cleaning; during ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com