Waste gas purification equipment with stink removal and VOCs (volatile organic compounds) degradation functions

A waste gas purification and equipment technology, which is applied in the direction of gas treatment, air quality improvement, chemical instruments and methods, etc., can solve the problems of discounted treatment effect, imperfect design, large equipment volume, etc., and achieve no secondary pollution and thorough gas purification Effective, low water consumption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

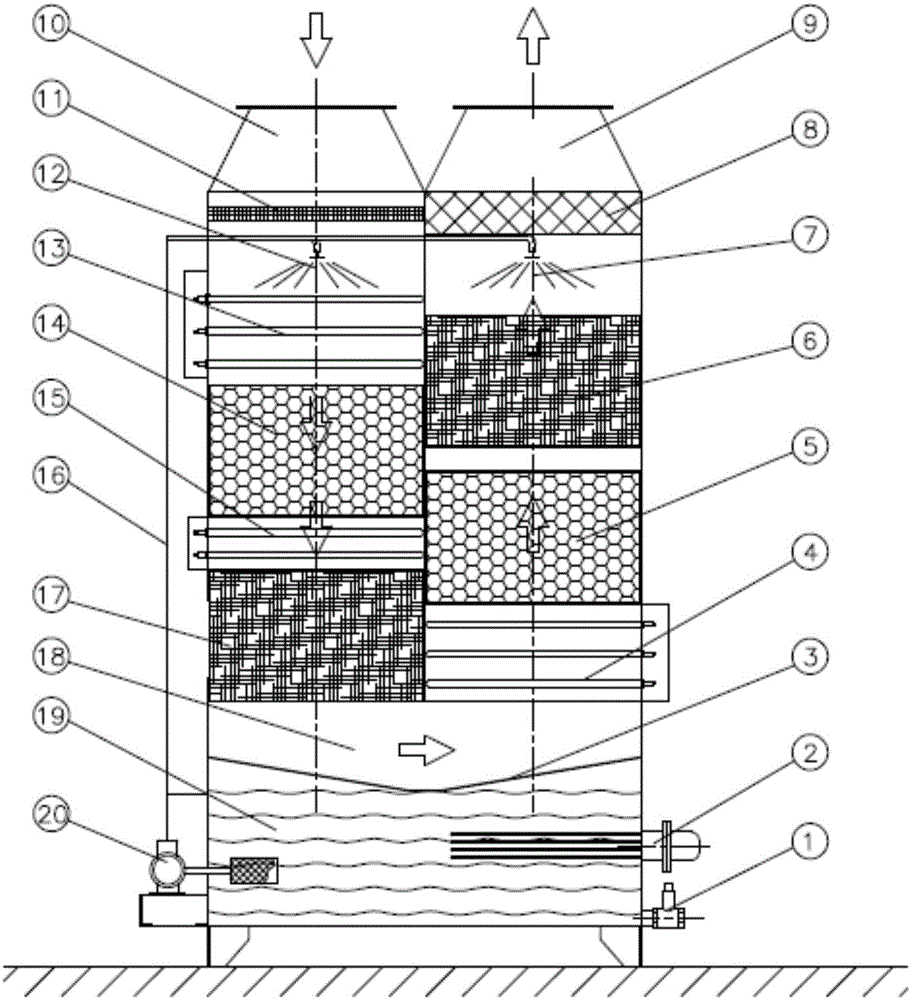

[0044] see figure 1 , the present invention discloses a waste gas purification equipment for deodorizing and degrading VOCs, the purification equipment includes a drain valve 1, a heater 2, an airflow channel 3, a third-stage oxidation section 4, a secondary spherical packing purification 5, and a secondary composite packing purification Section 6, circulation spray outlet 7, demister 8, variable diameter exit 9, variable diameter entrance 10, flow equalization device 11, circulation spray entrance 12, primary oxidation section 13, primary spherical packing purification section 14, secondary Oxidation section 15, spray pipe 16, primary composite filler purification section 17, equipment shell main body 18, water tank 19, circulation pump 20;

[0045] The bottom of the purification equipment is provided with an airflow channel 3, and the bottom of the airflow channel 3 is provided with a water tank 19, a circulation pump 20, a drain valve 1, and a heater 2, and the drain valve ...

Embodiment 2

[0051] see figure 1 In the embodiment of the present invention, the main body of the multi-stage oxidation biological method purification equipment purifier includes a drain valve 1, a heater 2, a V-shaped airflow channel (water collecting plate) 3, a third-stage oxidation section 4, and a second-stage spherical Packing purification 5, secondary composite packing purification section 6, circulation spray outlet 7, demister 8, variable diameter exit 9, variable diameter entrance 10, equalizer plate 11, circulation spray entrance 12, primary oxidation section 13, primary Grade spherical packing purification section 14, secondary oxidation section 15, spray pipe 16, primary composite packing purification section 17, equipment shell main body 18, water tank 19, circulation pump 20, etc. The water pipelines are equipped with solenoid valves and manual valves to facilitate automatic and manual operation.

[0052] The exhaust gas containing malodorous molecules and volatile organic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com