Laterally tilted feeding vertical-type grading powder-grinding machine

A milling machine and feeding technology, which is applied in grain processing, etc., can solve the problems of low grinding efficiency, difficult repair, high cost, etc., and achieve the effect of improving grinding and pressing efficiency, significant grading effect, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to deepen the understanding of the present invention, the following further describes the present invention with reference to the accompanying drawings and embodiments. The embodiments are only used to explain the present invention and do not limit the protection scope of the present invention.

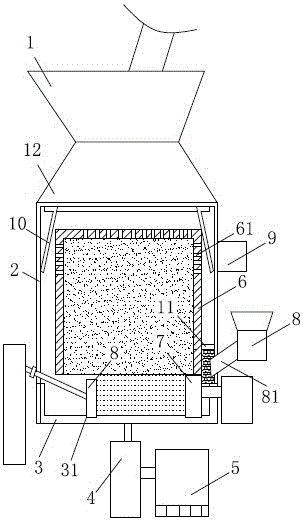

[0021] Such as figure 1 As shown, the vertical classifier mill with oblique side feeding includes a secondary fan 1, a classifier 12, a mill body 2, a mill disc 3, a reducer 4, and a motor 5 arranged in order from top to bottom. 2 is located above the grinding disc 3 with a powder sieving cover 6, and a number of sieving mesh holes 61 are provided near the top of the sieving cover 6; the grinding disc 3 is provided with coarse abrasive rollers 7 and at different positions along its circumference. The fine abrasive roller 8, in which the coarse abrasive roller 7 is located close to the edge of the grinding disc 3, and an inclined feeding device 8 is also provided in the to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com