Nuclear magnetic pipe rack

A nuclear magnetic tube and tube rack technology, which is applied in the field of experimental sample storage, can solve the problems of difficult operation, low firmness, smashing through the bottom, etc., and achieves the effects of improving mechanical strength, not easy to fall off, and avoiding breaking.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

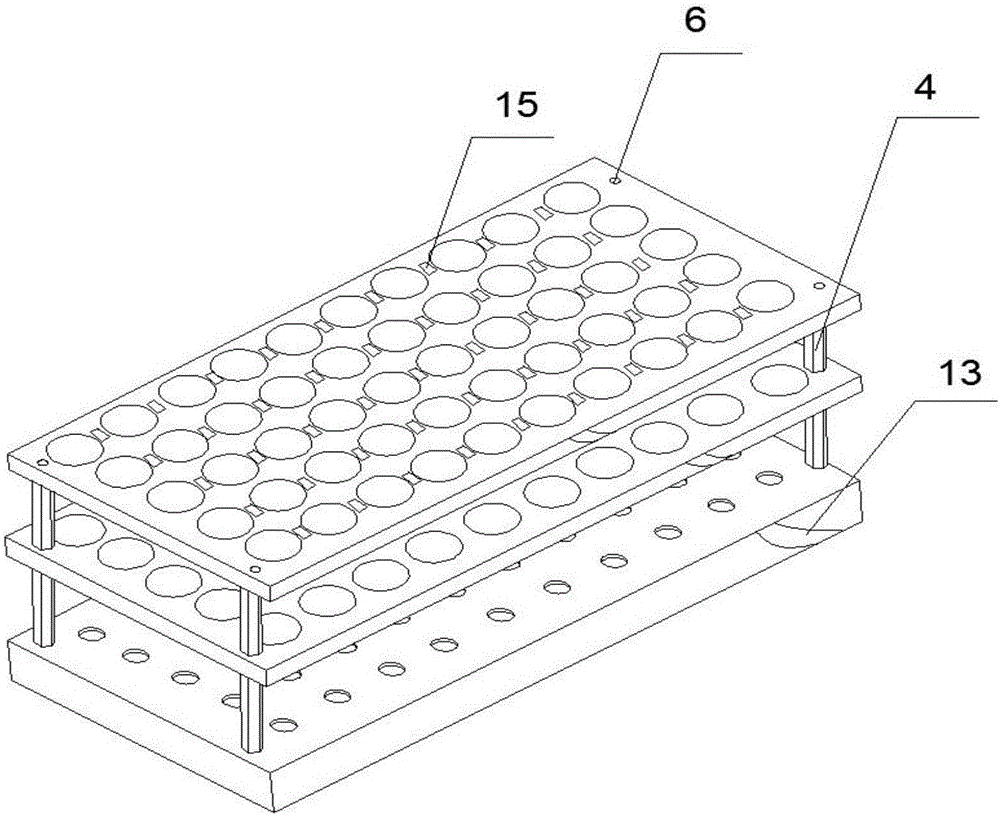

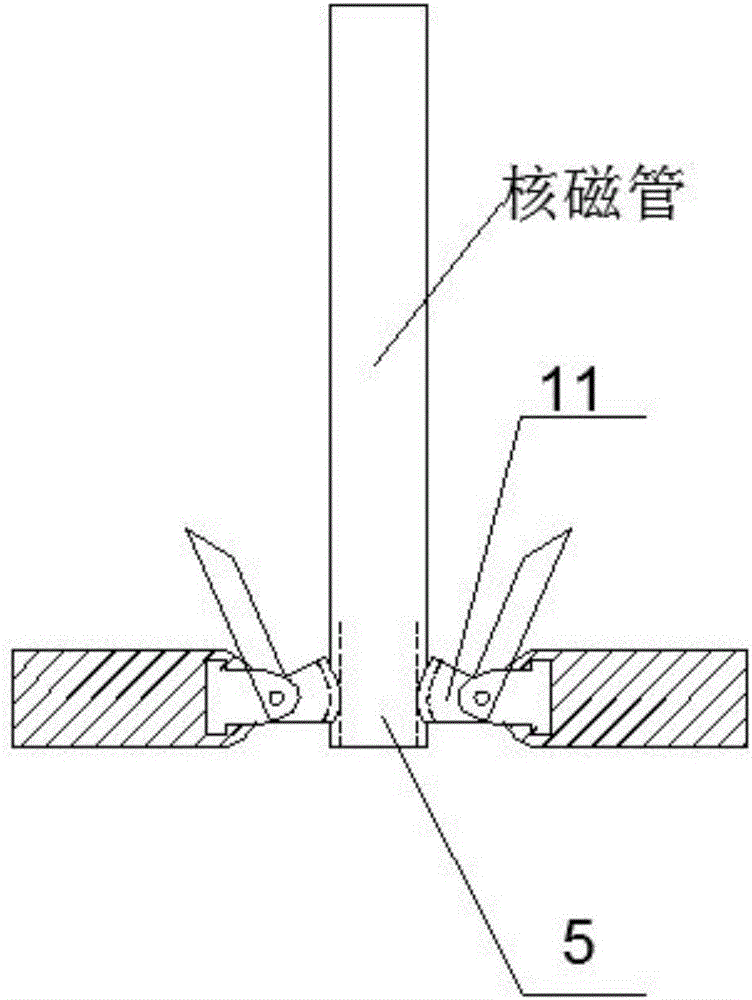

[0026] Embodiment 1: A nuclear magnetic tube frame, including a panel 1, a middle partition 2, a bottom plate 3, and a tube frame support column 4, and the panel 1, the middle partition 2, and the bottom plate 3 cooperate with the fixing screws 6 through the tube frame support column 4 Set at intervals in turn, the corresponding positions of the panel 1 and the middle partition 2 are provided with guide through holes 5, and the bottom plate 3 is provided with positioning holes 7 corresponding to the guide through holes 5 one by one. Plate 2, base plate 3 and fixing screws 6 are made of 6061 aluminum alloy which has been precisely processed by CNC machine tools, sand blasted and surface oxidized. The support column 4 of the pipe frame is a copper connecting column; Rubber foot pad 14, the rubber foot pad 14 is provided with a plurality of protrusions on the contact surface with the ground; the guide through hole 5 and the positioning hole 7 are chamfered to prevent the metal fra...

Embodiment 2

[0027]Embodiment 2: The difference between the nuclear magnetic tube frame described in this embodiment and the nuclear magnetic tube frame described in embodiment 1 is only that: the high-density elastic silica gel that is once molded is laid on the bottom plate, and the thickness of the high-density elastic silica gel is 2mm. The amount of the high-density elastic silica gel hardening catalyst is 1:50. The invention is applicable to the storage of nuclear magnetic tubes under general low temperature.

Embodiment 3

[0028] Embodiment 3: The difference between the nuclear magnetic tube rack described in this embodiment and the nuclear magnetic tube rack described in embodiment 1 is only that: the high-density elastic silica gel that is formed once is laid on the bottom plate, and the thickness of the high-density elastic silica gel is 2mm. The amount of the high-density elastic silica gel hardening catalyst is 1:75. The invention is applicable to the storage of nuclear magnetic tubes under general low temperature.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com