Graphene loaded cerium catalyst and preparation method thereof

A graphene and catalyst technology, applied in the field of graphene-supported cerium catalyst and its preparation, can solve the problems of poor recycling effect, reduced catalytic efficiency, and loss, and achieve easy recovery and recycling, simple method operation, and high catalytic activity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

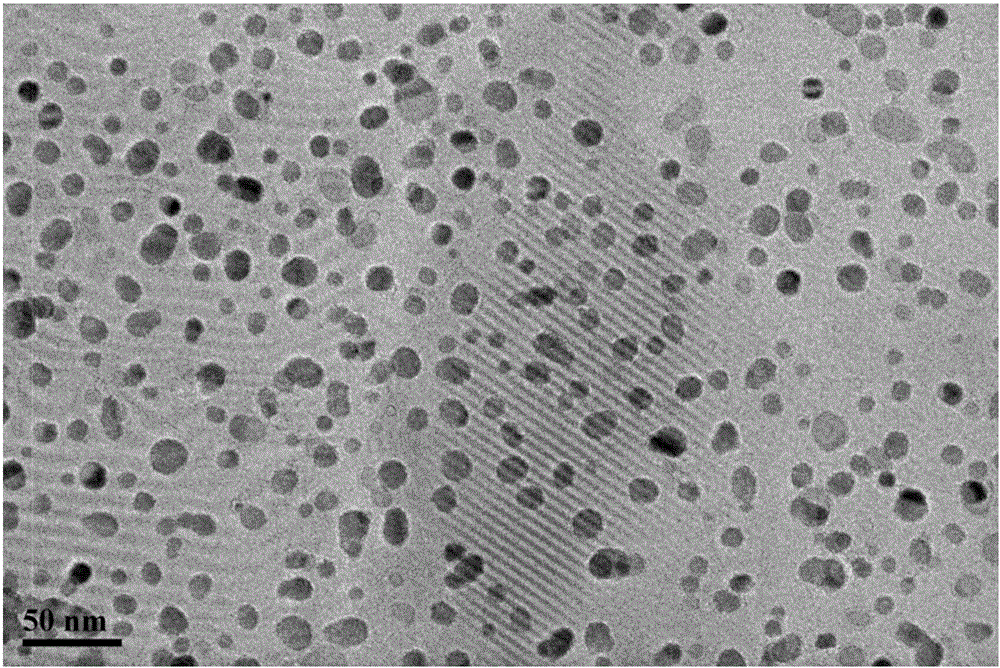

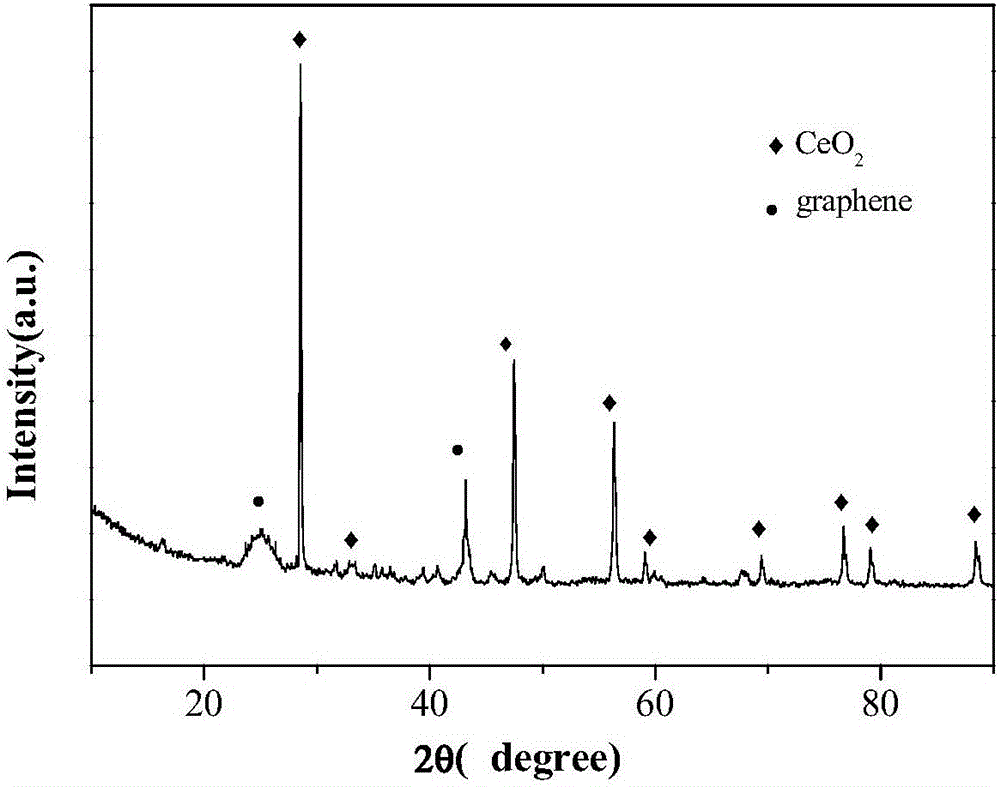

Image

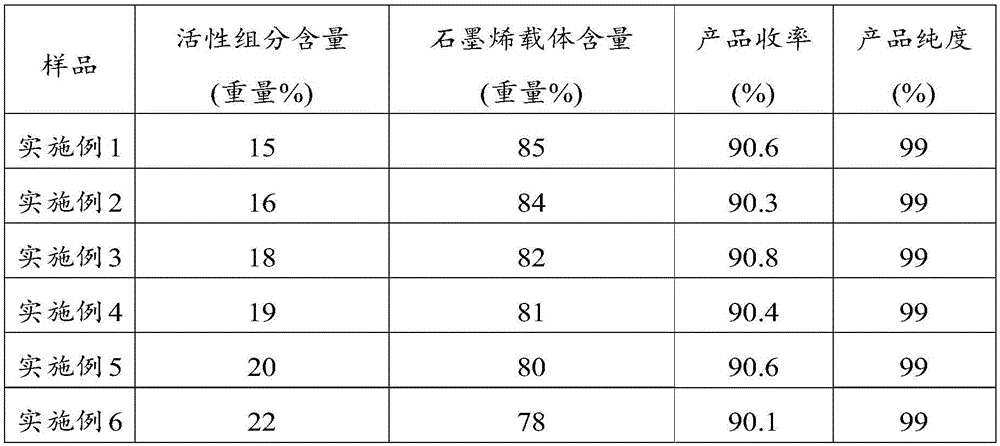

Examples

preparation example Construction

[0015] A kind of preparation method of graphene supported cerium catalyst that the embodiment of the present invention provides, it comprises the steps:

[0016] S1. Add the aqueous solution of cerium trichloride dropwise to the alcohol solution containing concentrated ammonia water, stir, and keep warm at a temperature of 40-60° C. for 1-1.5 hours to obtain a suspension of cerium oxide.

[0017] Specifically, the reaction principle is roughly that the cerium trichloride aqueous solution reacts with the alcohol solution containing concentrated ammonia water to form cerium hydroxide, which is unstable and decomposes into cerium oxide to form a cerium oxide suspension. The cerium trichloride aqueous solution is added dropwise to fully react the cerium trichloride aqueous solution with the alcohol solution of concentrated ammonia water, which improves the conversion rate of the reaction. The purpose of stirring is also to make the alcohol solution of cerium trichloride aqueous sol...

Embodiment 1

[0032] The present embodiment provides a kind of preparation method of graphene supported cerium catalyst, it comprises the following steps:

[0033] First, 0.20 g of anhydrous cerium trichloride was weighed and dissolved in 100 ml of deionized water, and fully dissolved to obtain a cerium trichloride solution. Add 50 ml of concentrated ammonia water-ethanol solution (1:1) dropwise to the above cerium trichloride solution, stir magnetically, and keep warm at 50° C. for 1 h to obtain a cerium oxide suspension.

[0034] Next, 1.20 g of graphene oxide was weighed, added to 50 ml of distilled water, and placed in an ultrasonic reactor with a power of 168 W for 2 hours to obtain a graphene oxide suspension.

[0035] Finally, after mixing the above-mentioned cerium oxide suspension and graphene oxide suspension, transfer them to a polytetrafluoroethylene-lined autoclave, react at 160°C for 8 hours to obtain a mixed solution, centrifuge the obtained mixed solution, and remove The su...

Embodiment 2

[0038] The present embodiment provides a kind of preparation method of graphene supported cerium catalyst, it comprises the following steps:

[0039] First, weigh 0.22 g of anhydrous cerium trichloride and dissolve it in 100 ml of deionized water to obtain a cerium trichloride solution after fully dissolving. Add 50 ml of concentrated ammonia water-ethanol solution (1:1) dropwise to the above cerium trichloride solution, stir magnetically, and keep warm at 50° C. for 1 h to obtain a cerium oxide suspension.

[0040] Next, 1.18 g of graphene oxide was weighed, added to 50 ml of distilled water, and placed in an ultrasonic reactor with a power of 168 W for 1.5 h to obtain a graphene oxide suspension.

[0041] Finally, after mixing the above cerium oxide suspension and graphene oxide suspension, transfer them to a polytetrafluoroethylene-lined autoclave, react at 168°C for 9 hours to obtain a mixed solution, centrifuge the obtained mixed solution, and remove The supernatant was ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com