A method for manufacturing a bionic automobile tail fin shell

A manufacturing method and bionic technology, applied in manufacturing tools, additive manufacturing, design optimization/simulation, etc., can solve problems such as inability to exhibit aerodynamic performance, achieve good aerodynamic characteristics, improve ride comfort, and wind resistance The effect of small coefficients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The manufacturing method of the bionic car tail fin shell with sparrow beak geometry feature of the present invention comprises the following steps:

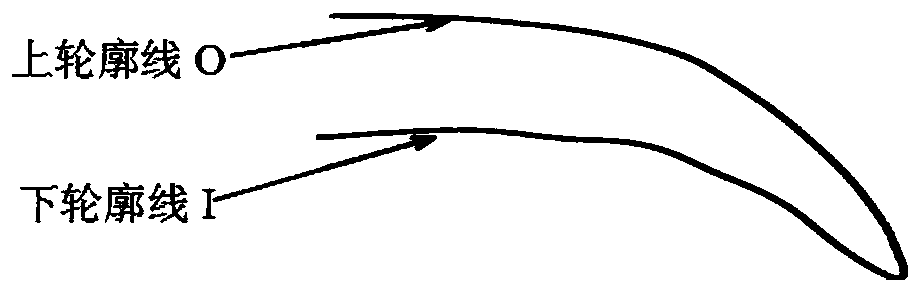

[0032] (1) Collection of sparrow mouth characteristics: Obtain several adult sparrows, and screen out sparrows with completely exposed mouth features and complete appearance. Cut it open, and draw the outer contour curve of the sparrow's beak longitudinal section on the coordinate paper (see figure 1 ); there are two outer contour curves of the characteristic longitudinal section of the sparrow mouth drawn, i.e. the upper contour curve O and the lower contour curve I, and then use the least squares method to fit the directrix equation of the mouth characteristic longitudinal section contour curve O ( Formula 1-1);

[0033]

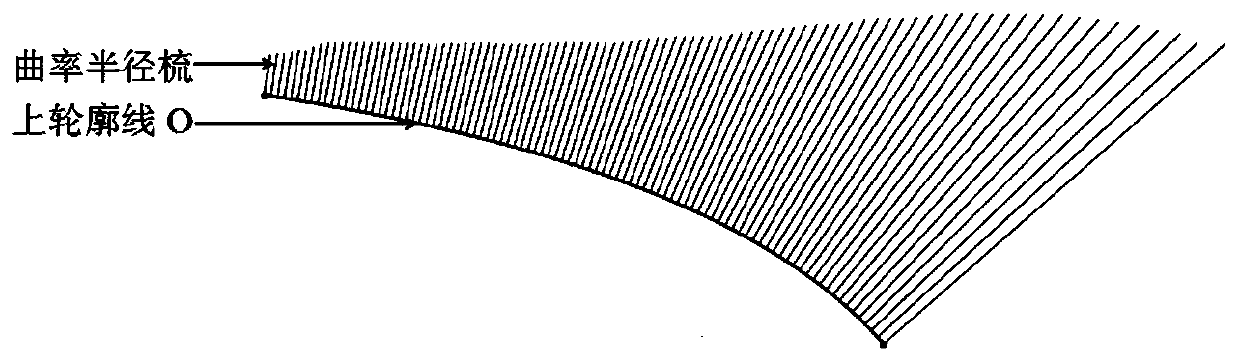

[0034] (2), the establishment of the bionic model of the caudal fin shell: the directrix equation of the contour curve O on the longitudinal section of the step (1) is imported into SolidWorks to ...

Embodiment 2

[0038] Step (1) and step (2) are with embodiment 1;

[0039] Step (3), preparation of the caudal fin shell: Design a mold matching it according to the bionic caudal fin shell model built in step (2), and then use carbon fiber reinforced resin-based composite materials for preparation. The carbon fibers used are laid by mixing three layers of fibers and into; among them, the laying angle of the three-layer fiber layer from top to bottom is [90 / 45 / 0] (see Figure 10 ), the 0 degree direction is the lateral direction of the caudal fin.

Embodiment 3

[0041] In order to reduce the drag coefficient of the tail fin of the car and further expand the application range of the bionic tail fin, the bottom of the bionic model of the tail fin of the car designed by the present invention can be cut arbitrarily according to the needs of the vehicle model, and the purpose is to make the tail fin fit closer to the roof; at the same time, it can The top of the bionic model is rounded and cut, and the bionic car tail fin shell with rounded corners and bottom cut is made, which specifically includes the following steps:

[0042] Step (1) is with embodiment 1;

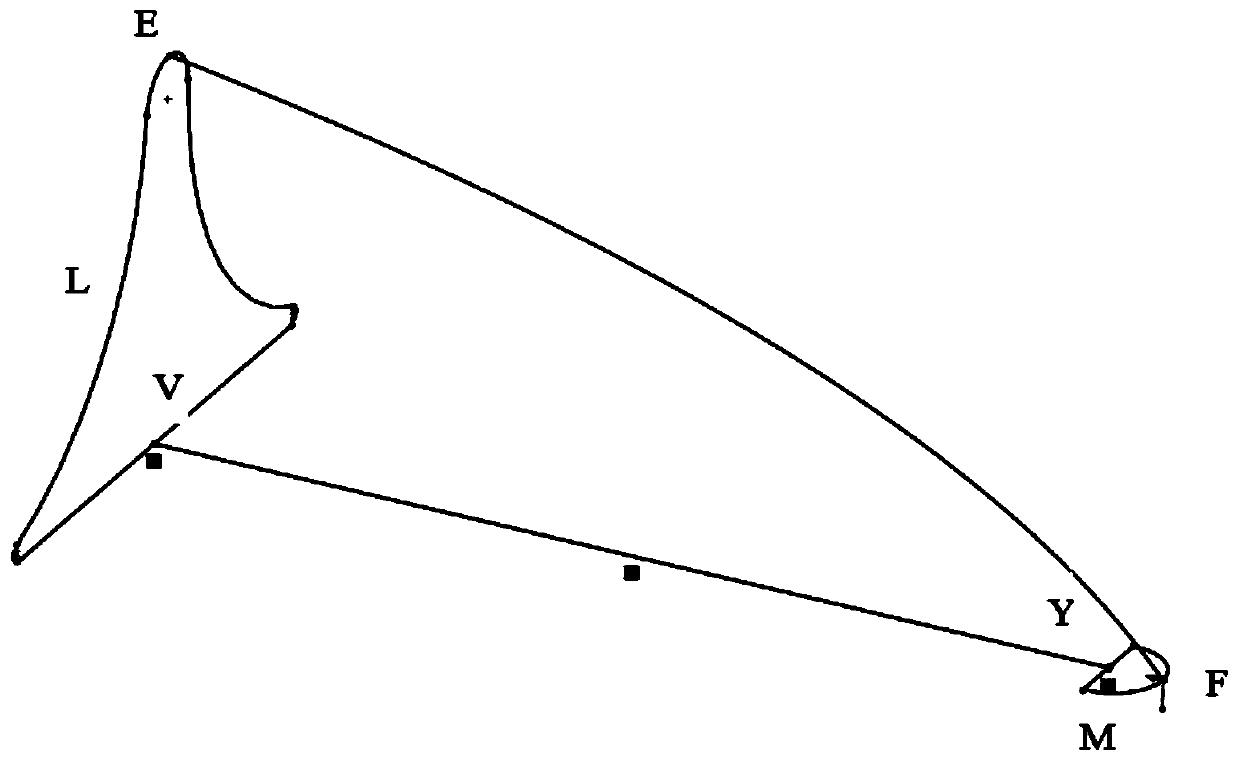

[0043] Step (2), after establishing the first contour line L and the second contour line M and setting out the boss, establish the cutting contour line in the plane of the reference plane Z=0; the cutting contour line is formed by the sixth arc HJ , composed of the fourth straight line HK and the fifth straight line KJ (see Figure 7 ); For example: in order to make the bottom of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com