A thermal functional composite material and its preparation method and application

A functional composite material and composite material technology, which is applied in the field of solid-liquid phase change composite materials, can solve the problem of inability to meet the use requirements of reversible mutation materials of thermal conductivity, and achieve strong temperature regulation ability, improve thermal conductivity mutation, regulation and control. fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

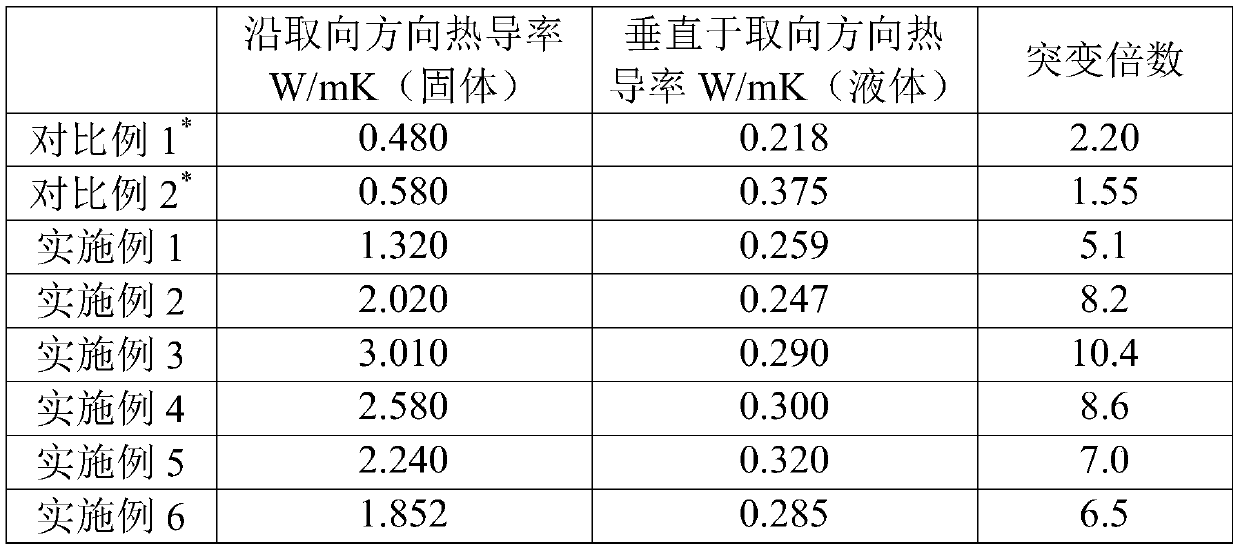

Examples

Embodiment 1

[0036](1) Disperse 100 g of boron nitride with a diameter of 5 microns and a thickness of 100 nanometers into 1 L of water, then add 1 mol / L sodium polystyrene sulfonate and 1 mol / L hydrochloric acid to adjust the pH value to about 4.0 , to ensure complete adsorption of sodium polystyrene sulfonate on boron nitride. Then filter and wash with water and acetic acid three times, and then dry, redisperse the boron nitride adsorbed with sodium polystyrene sulfonate in deionized water, add ferrous chloride and ferric chloride, and add 1,6 - Hexamethylenediamine, until a dark brown suspension is obtained, the amine molecules are washed away with water, and dried at 70° C. to obtain orientable heat-conducting particles under the action of a magnetic field (ie, magnetized boron nitride).

[0037] (2) Heat 100 parts by weight of solid PEG4000 to a liquid state, put it in a water bath to control the temperature and stir above its phase transition temperature, and add 5 parts by weight of...

Embodiment 2

[0039] Others are the same as in Embodiment 1, only the magnetic field intensity is adjusted from 20mT to 60mT.

Embodiment 3

[0041] Others are the same as embodiment 2, only changing boron nitride into graphene.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com