A jet integrated pump for ultra-high heat flux temperature control and its assembly method

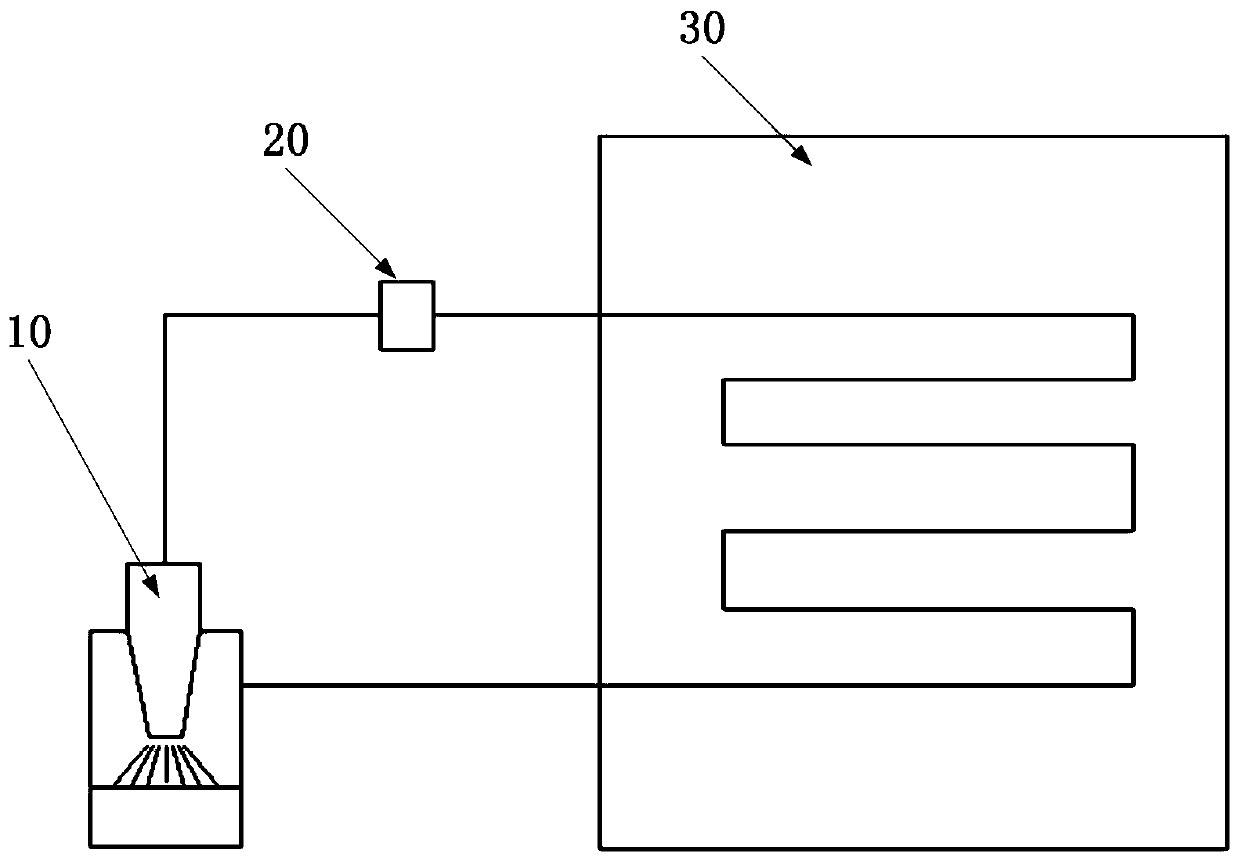

A technology with high heat flux density and high heat flux, applied in jet pumps, pump devices, assembly machines, etc., it can solve the problem that the jet cooling device cannot meet the cooling effect and the requirements of small size and light weight at the same time, and achieves compact structure and temperature control ability. Strong and reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

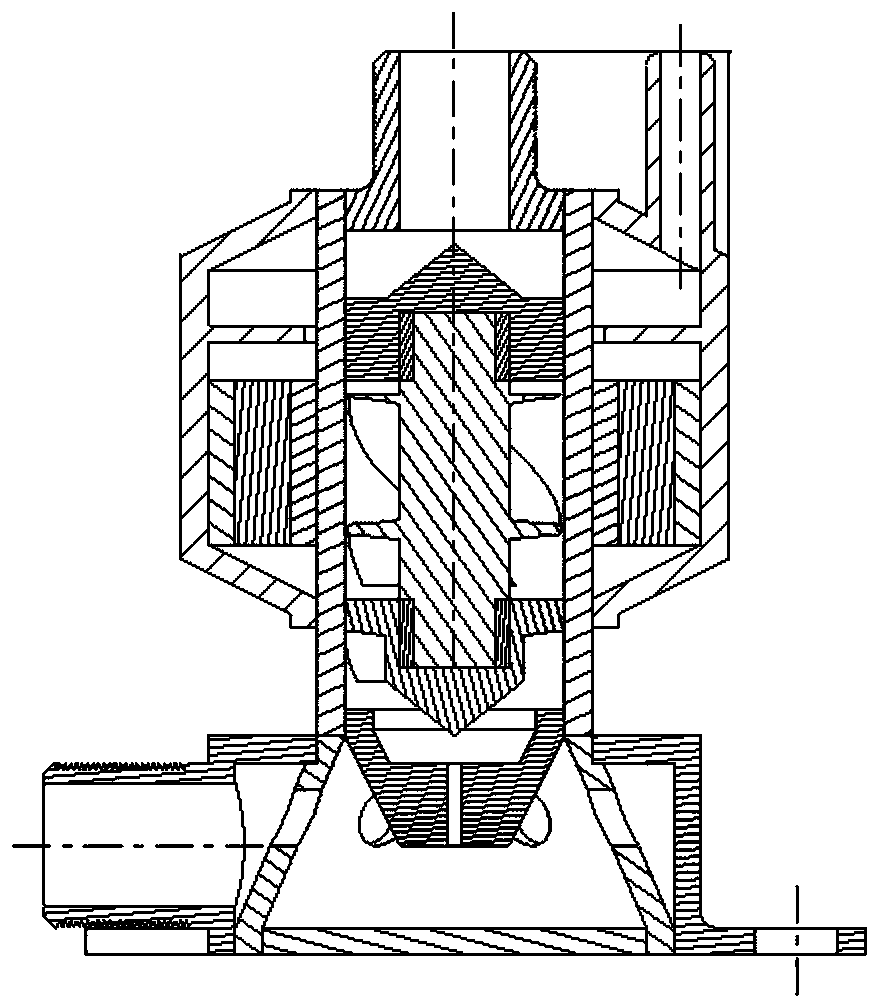

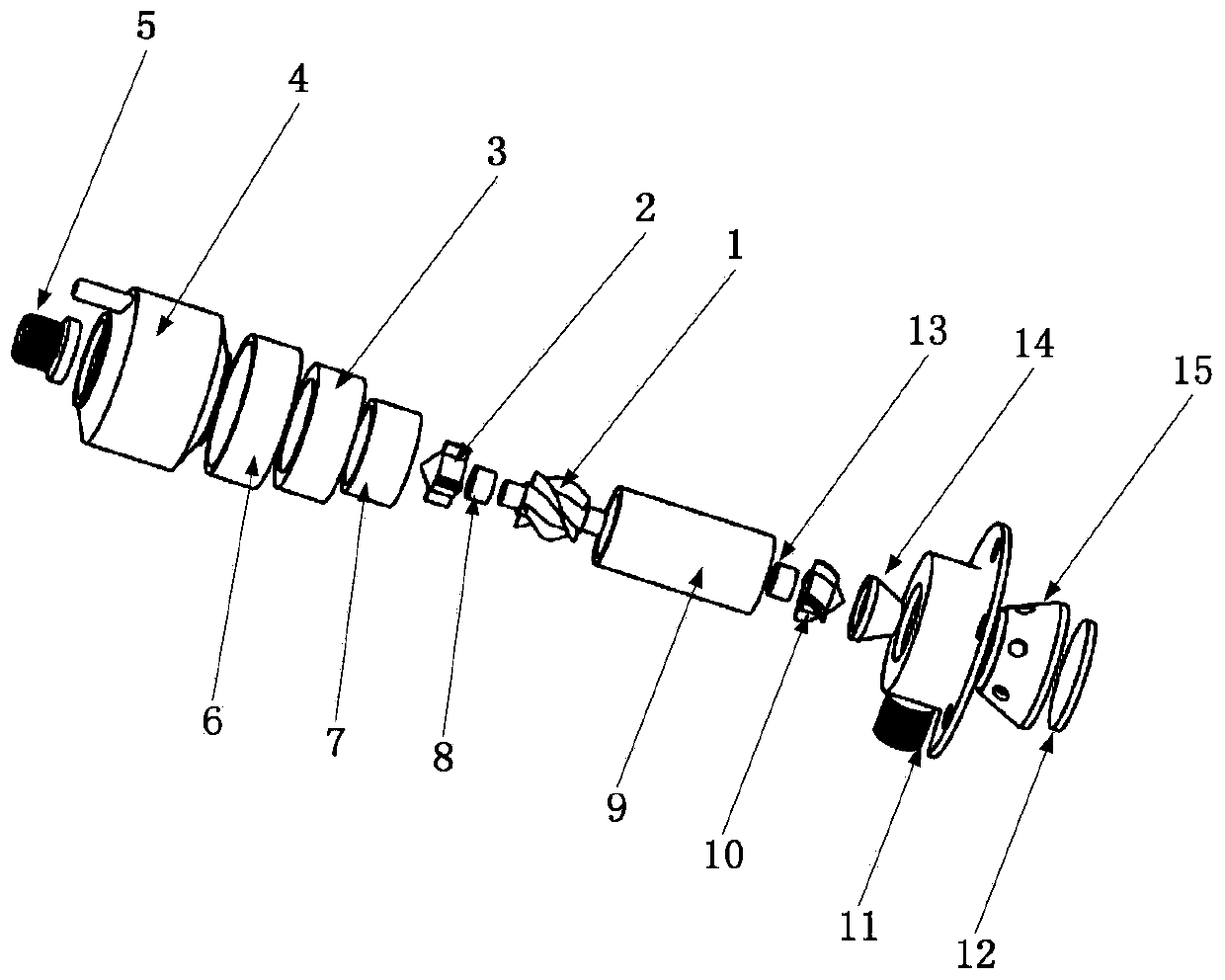

[0039] The specific implementation of the micro-jet integrated pump for ultra-high heat flux temperature control provided by the present invention is as follows:

[0040] Process 1: Component Processing

[0041] Each component is processed according to the specific drawings. The joints, electrical casing, rotor, pump casing, front and rear cones, nozzles, drainage rings, and confluence parts of the present invention are all made of titanium alloy; the heat sink part is made of high-strength aluminum alloy; the inner magnet of the rotor is made of NdFeB strong magnetic steel; hollow cup windings are customized according to the electromagnetic design results, and are wound with silver-plated copper enameled wires, and the windings are connected in a three-phase star shape.

[0042] Process 2: Assembly

[0043] Assemble the components according to the assembly drawing. The assembly process is as follows:

[0044] Step 1. Assemble the front and rear cones, bearings and impeller...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com