Loop heat pipes for solar energy water heater

A technology of solar water heater and loop heat pipe, applied in the field of solar heat pipe, can solve the problems of reducing transmission power, affecting the diameter of steam chamber, complicated manufacturing process, etc., and achieving the effect of increasing transmission power, solving single installation and wide application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

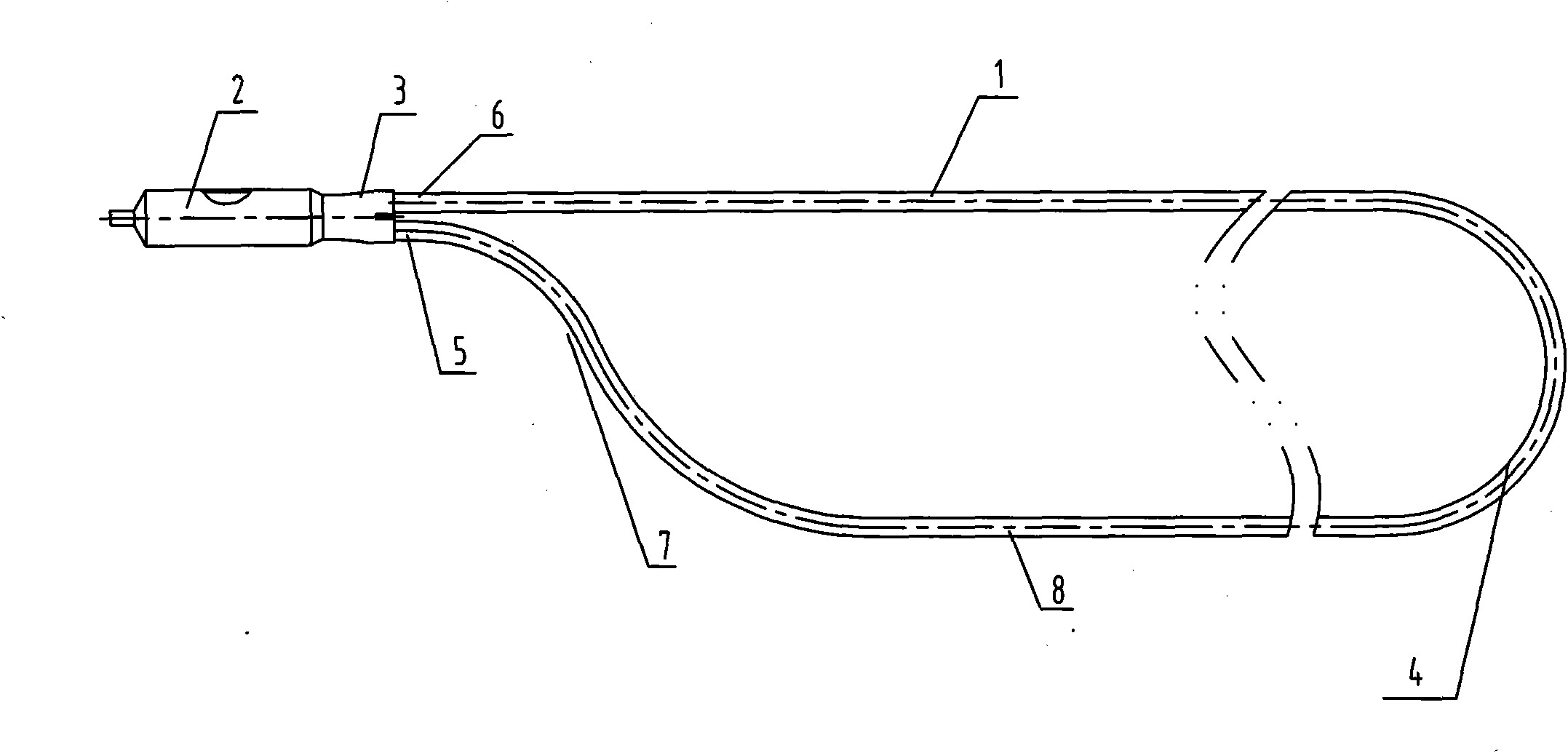

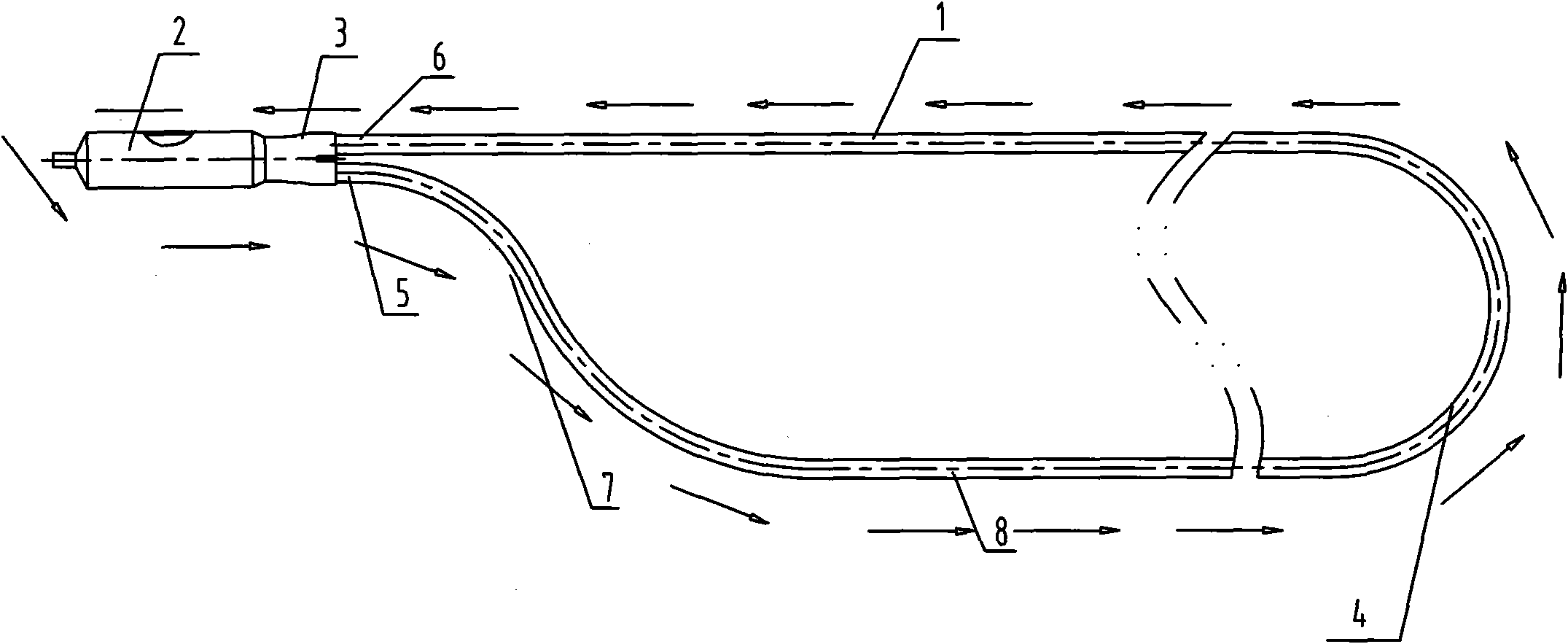

[0020] This embodiment is a loop heat pipe for a solar water heater, with a structure such as figure 1 As shown, it includes evaporating section 1, condensing section 2 and adiabatic section 3. The adiabatic section 3 is located between evaporating section 1 and condensing section 2. Working medium is provided in the heat pipe shell of evaporating section 1. Evaporating section 1 is composed of two sections of tubes. The road is connected into a loop pipe through a section of semi-circular arc pipe 4. The front section of the evaporation section 1 has a narrower structure than the middle section and the back section of the evaporation section. The two pipelines in the front section of the evaporation section 1 are connected to the adiabatic section 3 through the vapor working medium outlet 6 and the liquid working medium inlet 5 near the adiabatic section, and the two pipelines of the evaporation section 1 are connected to the pipeline of the vapor working medium outlet 6 The...

Embodiment 2

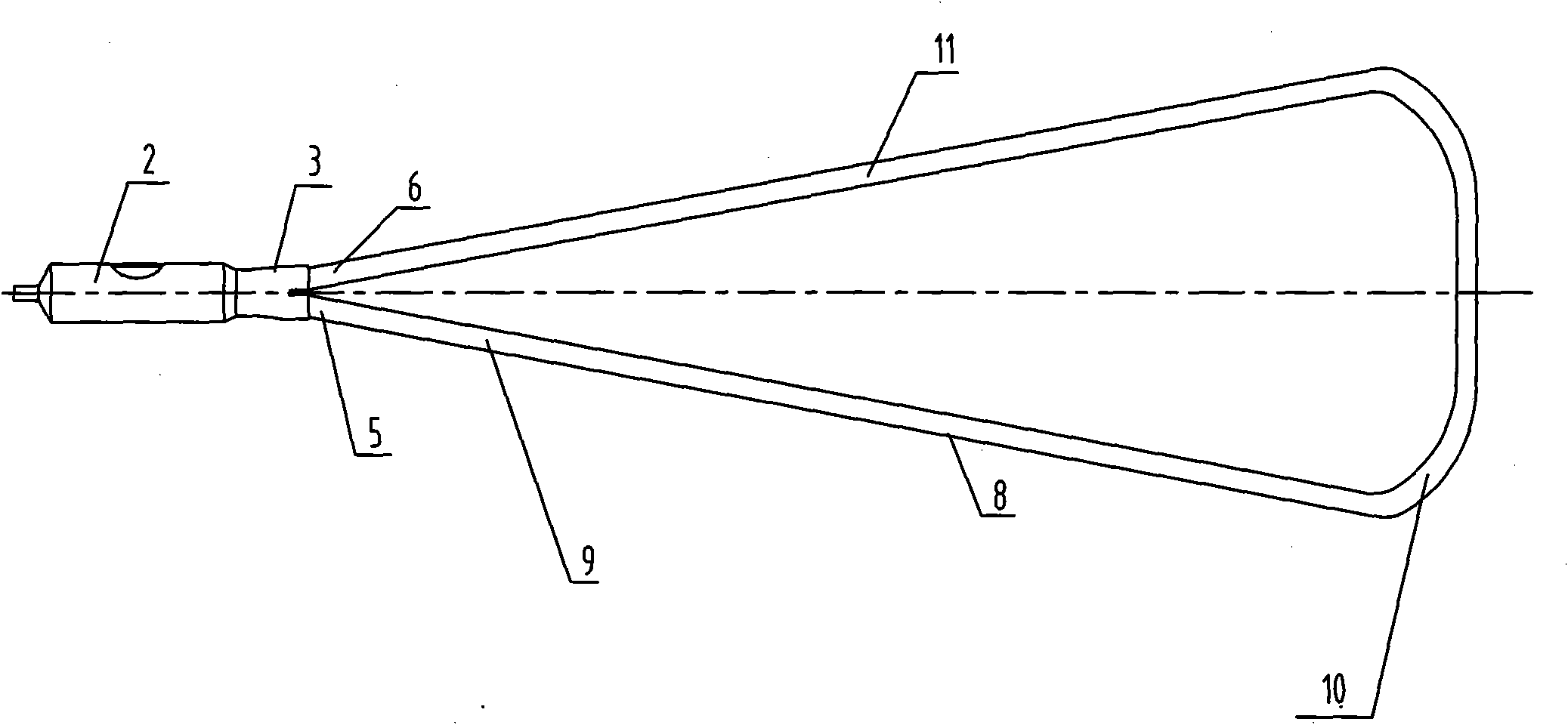

[0023] This embodiment is another kind of structural loop heat pipe for solar water heaters, the structure is as image 3 As shown, the principle of this embodiment is the same as that of Embodiment 1, and the difference in structure is that the liquid working medium inlet 5 of the evaporating section 1 is connected to the arc tube 10 through a downwardly inclined straight tube 9, and the arc tube 10 is connected with a vapor tube. The downward-sloping straight pipe 11 of the state working medium outlet 6 has a conical cross-section in the entire evaporation section. In the evaporating section 1, the heat pipe with the vapor working medium outlet 6 is an inclined straight pipe 11, and the heat pipe with the liquid working medium inlet 5 in the other section is also an inclined straight pipe 9, which is conducive to the smoother flow of the vapor working medium. The heat transfer capacity of the heat pipe is increased. The arc tube 10 is used to connect the elbow, which streng...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mesh | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com