Power frequency epoxide filling and sealing transformer used for electrostatic oil smoke removing device

A technology for potting transformers and oil fume equipment, applied in the field of transformers, can solve the problems of accelerating the aging and deterioration of transformer components, weak anti-interference ability, and expansion of insulating materials, and achieve the effects of weight reduction, material saving, and small partial discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

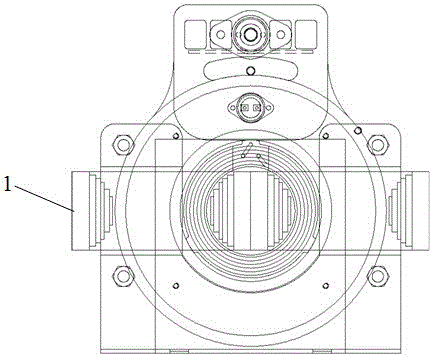

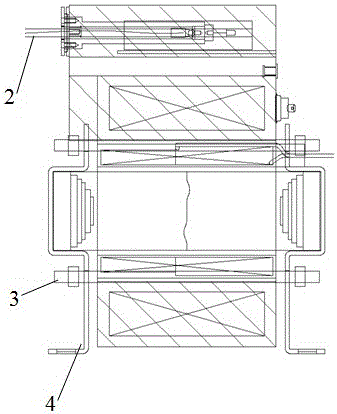

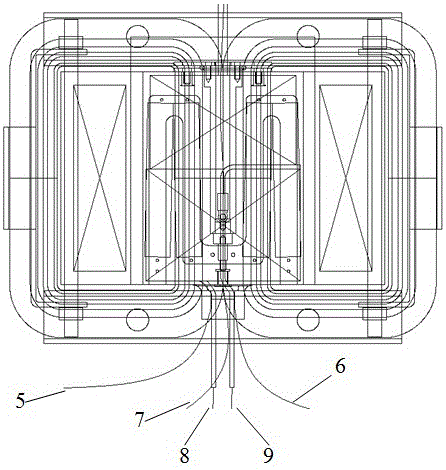

[0027] control figure 1 As shown in -9, the frame 4 on both sides of the transformer is fixed in the correct relative position through the connecting screw 3, and the low-voltage package of the device is installed between the frame 4, and the two sides of the low-voltage package are iron cores 1, and the aforementioned frame 4 The upper part of the device is installed with the high voltage package of the device. The interior of the high-voltage package is equipped with a temperature sensor, and is connected to the thermostat 12 through the temperature-sensing line 1 6, temperature-sensing line 2 5, and feedback line 7. one end. The low-voltage package includes iron core 1, coil 13, low-voltage line 1 8 and low-voltage line 2 9, iron core 1 is installed inside the frame 4, coil 13 is wound on iron core 1, low-voltage line 1 8 and low-voltage line 2 9 are formed by The low-voltage pack is internally drawn. The superimposed installation of the high-pressure package and the low...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com