Single-phase multiferroic ceramic material and preparation method thereof

A multiferroic ceramic, single-phase technology, applied in the field of single-phase multiferroic ceramics and its preparation, can solve the problems of weak ferromagnetism of bismuth ferrite, etc., and achieve the effect of simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

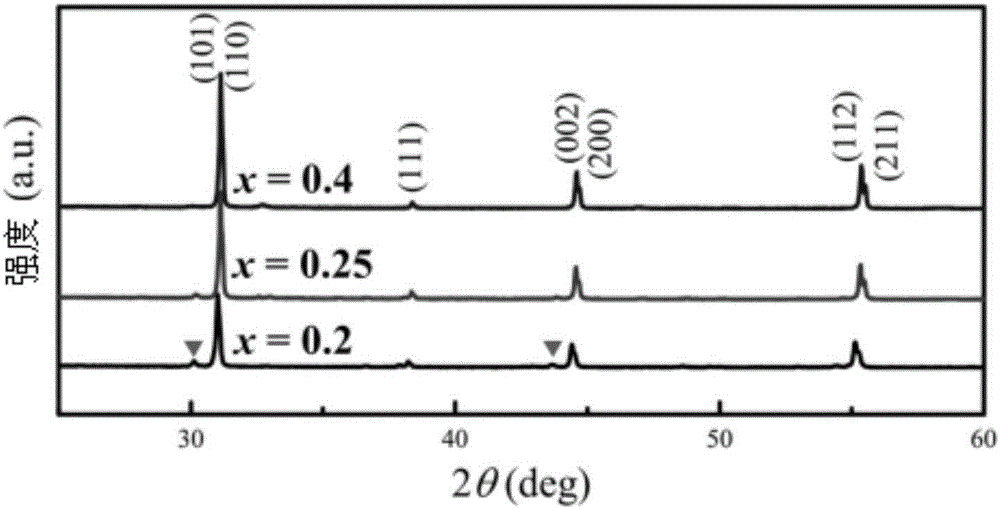

[0030] Specific embodiment one: the chemical expression of the single-phase multiferroic ceramic material of this embodiment is (1-x)Ba(Zr 0.2 Ti 0.8 )O 3 –x(Ba 0.7 Ca 0.3 )(Fe 0.5 Ta 0.5 )O 3 , where x=0.2~0.4, abbreviated as BXT.

specific Embodiment approach 2

[0031] Specific embodiment two: the preparation method of the single-phase multiferroic ceramic material described in specific embodiment one, carries out according to the following steps:

[0032] 1. Barium carbonate (BaCO 3 ), calcium carbonate (CaCO 3 ), titanium dioxide (TiO 2 ), ferric oxide (Fe 2 o 3 ), tantalum pentoxide (Ta 2 o 5 ) and zirconium dioxide (ZrO 2 ) powder according to

[0033] (1-x)Ba(Zr 0.2 Ti 0.8 )O 3 –x(Ba 0.7 Ca 0.3 )(Fe 0.5 Ta 0.5 )O 3 The stoichiometric ratio is weighed and mixed uniformly to obtain a mixed powder, wherein x=0.2~0.4;

[0034] 2. Add alcohol to the mixed powder obtained in step 1, and ball mill in a ball mill at a speed of 200-400rpm for 12-48 hours to obtain a suspension A;

[0035] 3. Dry the suspension A obtained in step 2 to obtain powder A, and then put the powder A into a tube furnace and keep it at a temperature of 1100-1250°C for 3-6 hours to obtain a pre-calcined powder ;

[0036] 4. Add alcohol to the calc...

specific Embodiment approach 3

[0039] Embodiment 3: This embodiment differs from Embodiment 2 in that the drying temperature in Step 2 is 80° C. to 100° C. Others are the same as Embodiment 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average grain size | aaaaa | aaaaa |

| Average grain size | aaaaa | aaaaa |

| Average grain size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com