System and method for preparing high-purity tetrapropylammonium hydroxide through electrolysis method

A technology of tetrapropyl ammonium hydroxide and tetrapropyl ammonium bromide, applied in the field of electrochemistry, can solve the problems of poor product quality and low TPAOH current efficiency of a single-membrane electrolysis device, and achieve the effects of avoiding corrosion and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

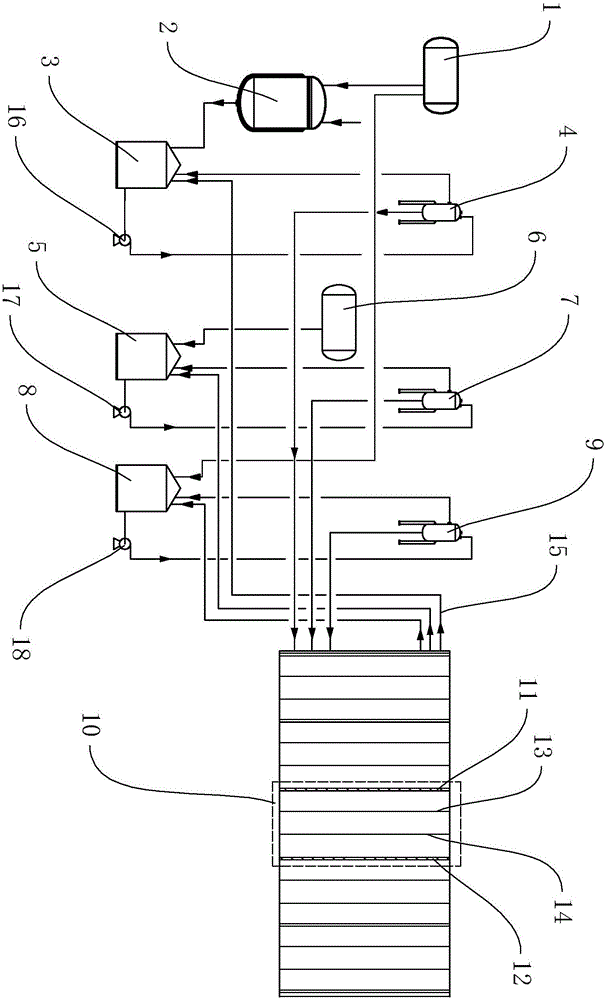

Method used

Image

Examples

Embodiment 2-9

[0047] According to the electrolysis device of embodiment 1, RuO 2 -TiO 2 / Ti replaced by carbon steel / carbon steel, IrO 2 -Ta 2 o 5 / Ti, titanium / titanium, and different types of diaphragm materials were used to prepare 7.5% high-purity TPAOH solution by continuous electrolysis. The process parameters were the same as in Example 1, and the results are shown in Table 1.

[0048] Table 1 Experimental results of electrolytic synthesis of TPAOH solution with different electrode materials and diaphragm materials

[0049]

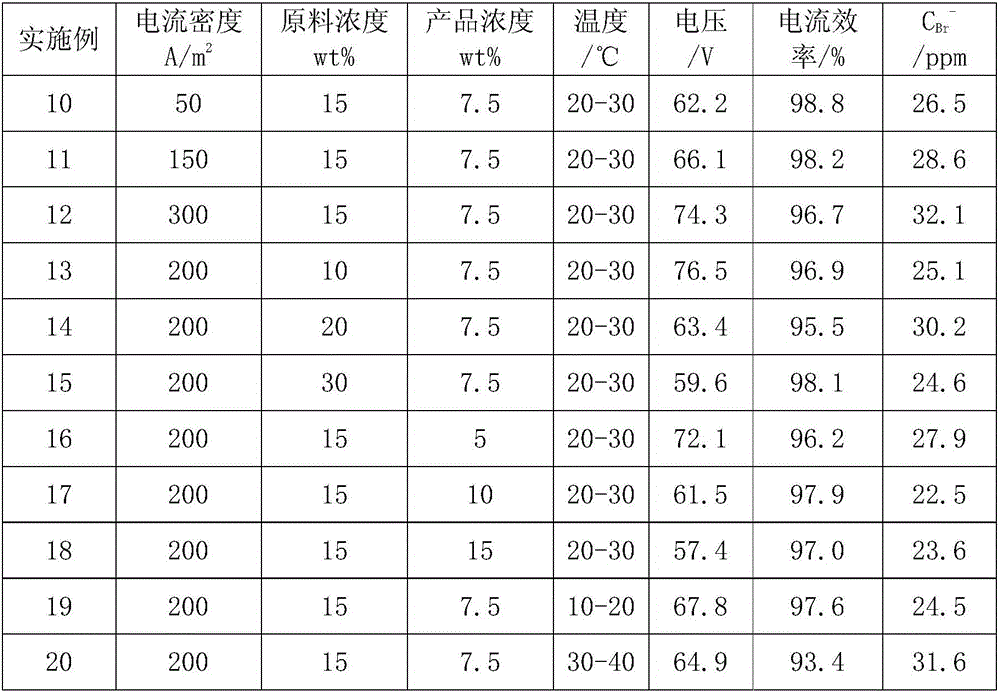

Embodiment 10-20

[0051] According to the electrolysis device of embodiment 1, RuO 2 -TiO 2 / Ti is a bipolar electrode, the cation exchange membrane 1 / anion exchange membrane 1 is a diaphragm material, different current densities are used, the intermediate chamber maintains different raw material concentrations, the concentration of electrolyte overflow products in the cathodic chamber, and the temperature of the electrolyte are different. Prepare 7.5% high-purity TPAOH solution under electrolysis process conditions, and the additional flow rate of raw materials and ammonia water is calculated according to the theoretical electricity. The results are shown in Table 2.

[0052] Table 2 Experimental results of electrolytic synthesis of TPAOH solution by different electrolytic processes

[0053]

Embodiment 21

[0055] According to the electrolysis device of embodiment 1, the unit electrolyzer quantity is 50, adopts 25 to connect in series, connects in two-way parallel mode. Add 5wt% ammonia water to the anolyte storage tank, add 25wt% TPABr solution to the middle tank storage tank, and add 1wt% TPAOH solution to the cathode storage tank. With the method of constant current intermittent electrolysis, the electrolysis current is 200A, the temperature is controlled from room temperature to 30°C, and the concentration of TPAOH in the electrolyte solution in the cathode area is electrolyzed to 7.5%. Control the electrolyte in the anode area to be pH<8 alkaline (if it is found to be weakly acidic, add ammonia water). After the electrolysis is finished, the TPAOH product in the cathode area is released, and the TPABr solid is added until the concentration of the solution in the middle tank is 25 wt%. The voltage of the experimental tank is 200-150V, the current efficiency is 96.23%, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com