Preparation method for synthesizing Cu-SSZ-39 molecular sieve based catalyst by using one-step method and application

A molecular sieve and catalyst technology, which is applied in the field of preparing Cu-SSZ-39 catalysts by double-template one-step method, can solve the problems of high industrial application cost, long catalyst preparation period, complicated steps, etc., achieve high crystallinity and avoid ion exchange. And calcination process, the effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

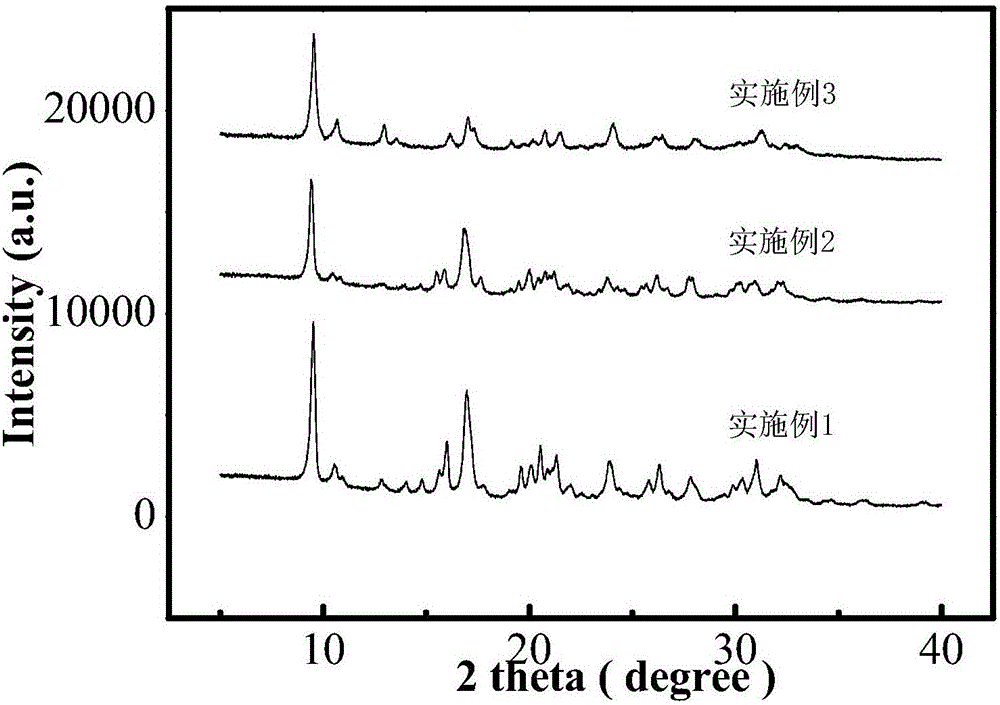

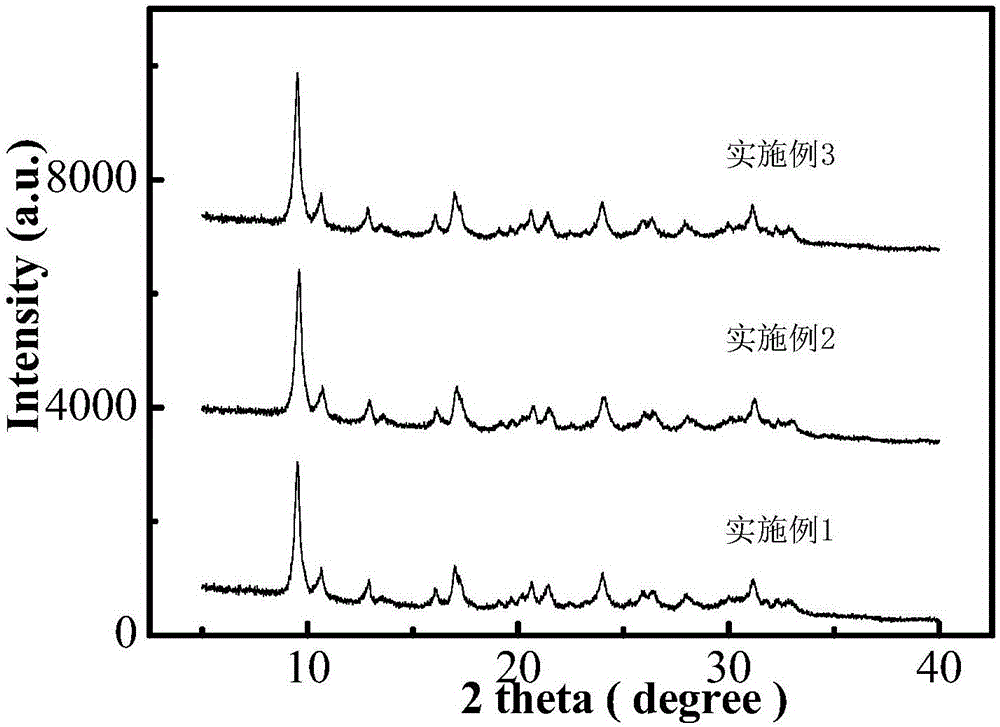

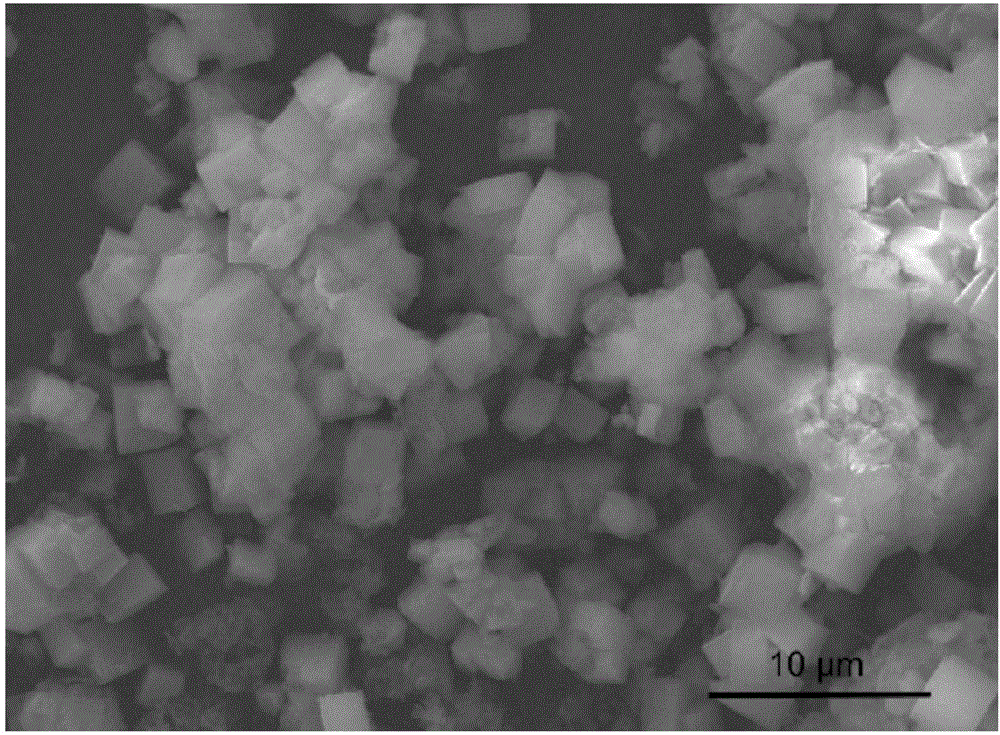

Embodiment 1

[0022] Take Commercial NH 4- Y (Si / Al=5.3) zeolite 10g, placed in a tube furnace and dealuminated under steam at 700°C for 4h, and then treated the dealuminated Y-type molecular sieve in a sulfuric acid solution with a concentration of 0.74M at 75°C for 4h , USY molecular sieves were obtained as aluminum and silicon sources for the synthesis of Cu-SSZ-39. Mix 20g of tetraethylphosphine bromide and 100g of deionized water evenly, then add 10g of hydroxide ion exchange resin, stir in a water bath at 30°C for 3 hours, and then filter to obtain the tetraethylhydrogen template required for the synthesis of Cu-SSZ-39 Phosphorus oxide. The raw materials for each reaction, namely silicon dioxide, aluminum oxide, copper sulfate-tetraethylenepentamine, organic mold, sodium oxide, water and templating agent, are fed according to the molar ratio of 1.0:0.04:0.025:0.6:0.3:30 , wherein the organic template is tetraethylphosphine hydroxide, the silicon source and the aluminum source are US...

Embodiment 2

[0024] The amount of each reaction raw material, namely silica, alumina, organic mold, sodium oxide, water and templating agent, is fed according to the molar ratio of 1.0:0.04:0.6:0.3:30, wherein the organic template is tetraethyl The base phosphine hydroxide, silicon source and aluminum source are USY molecular sieves. The fully stirred gel was placed in a hydrothermal reactor for reaction, cooled to room temperature after the reaction was completed, centrifugally filtered, washed with deionized water, dried, and calcined at 550°C to obtain Na-SSZ-39 molecular sieve catalyst. Take 10g of Na-SSZ-39 molecular sieve and place it in 500ml of ammonium nitrate solution with a concentration of 1.0M. After 12h in an oil bath at 80°C, wash and filter with distilled water, and dry at 110°C for 12h. Repeat the above steps to obtain NH 4 - SSZ-39 molecular sieve. 5g NH 4 -Add 5ml of SSZ-39 molecular sieve to dissolve 0.625g Cu(CH3COO) 2 In the aqueous solution, ultrasonic for 2h, the...

Embodiment 3

[0026] The amount of each reaction raw material, namely silica, alumina, organic mold, sodium oxide, water and templating agent, is fed according to the molar ratio of 1.0:0.04:0.6:0.3:30, wherein the organic template is tetraethyl The base phosphine hydroxide, silicon source and aluminum source are USY molecular sieves. The fully stirred gel was placed in a hydrothermal reactor for reaction, cooled to room temperature after the reaction was completed, centrifugally filtered, washed with deionized water, dried, and calcined at 550°C to obtain Na-SSZ-39 molecular sieve catalyst. Take 10g of Na-SSZ-39 molecular sieve and place it in 500ml of ammonium nitrate solution with a concentration of 1.0M. After 12h in an oil bath at 80°C, wash and filter with distilled water, and dry at 110°C for 12h. Repeat the above steps to obtain NH 4 - SSZ-39 molecular sieve. 5g NH 4 -SSZ-39 molecular sieve placed in Cu(CH3COO) at a concentration of 0.15M 2 In the aqueous solution, after 12 hours...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com