Method and system for realizing circuit ZVS (Zero Voltage Switch) based on delay time

A delay time, circuit technology, applied in electrical components, induction heating, power oscillators, etc., can solve problems such as inability to guarantee circuits, IGBT burnout, occupation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

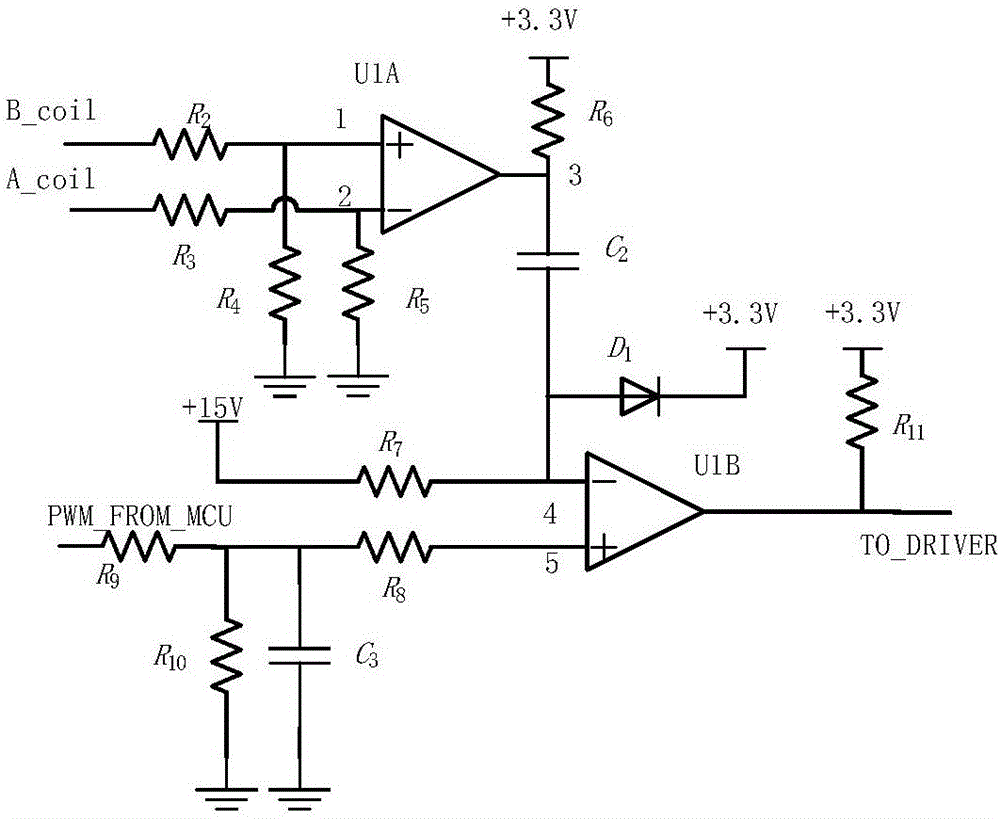

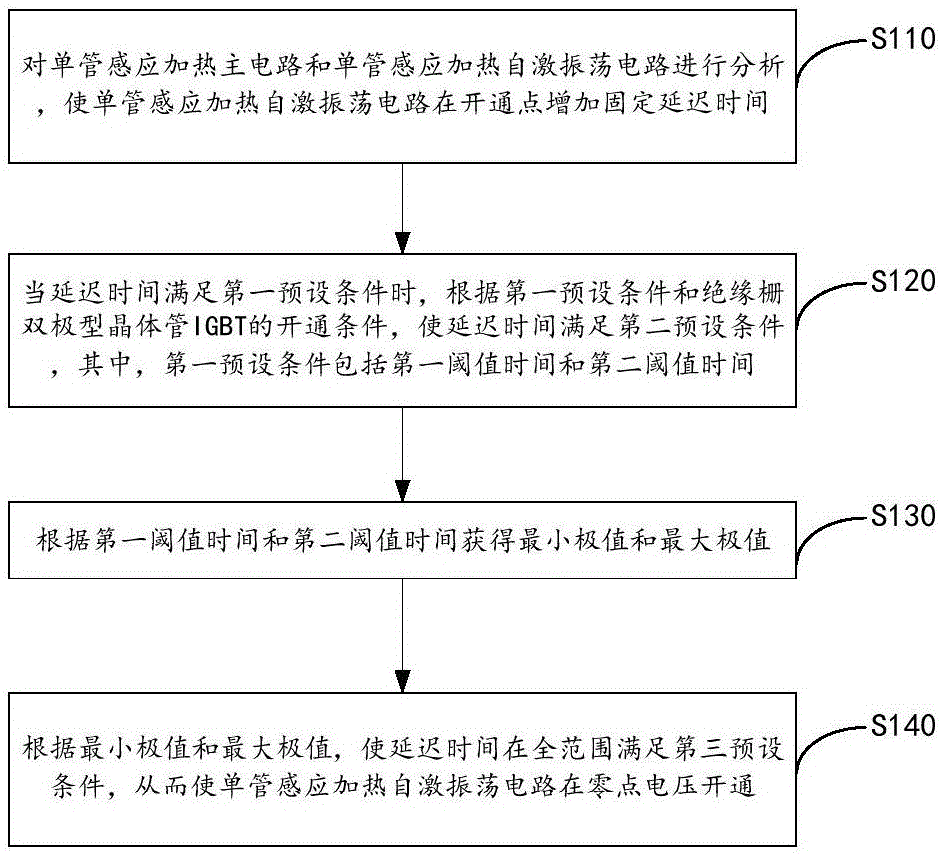

[0056] image 3 A flow chart of a method for implementing circuit ZVS based on delay time provided by Embodiment 1 of the present invention.

[0057] refer to image 3 , the method to achieve circuit ZVS based on the delay time includes:

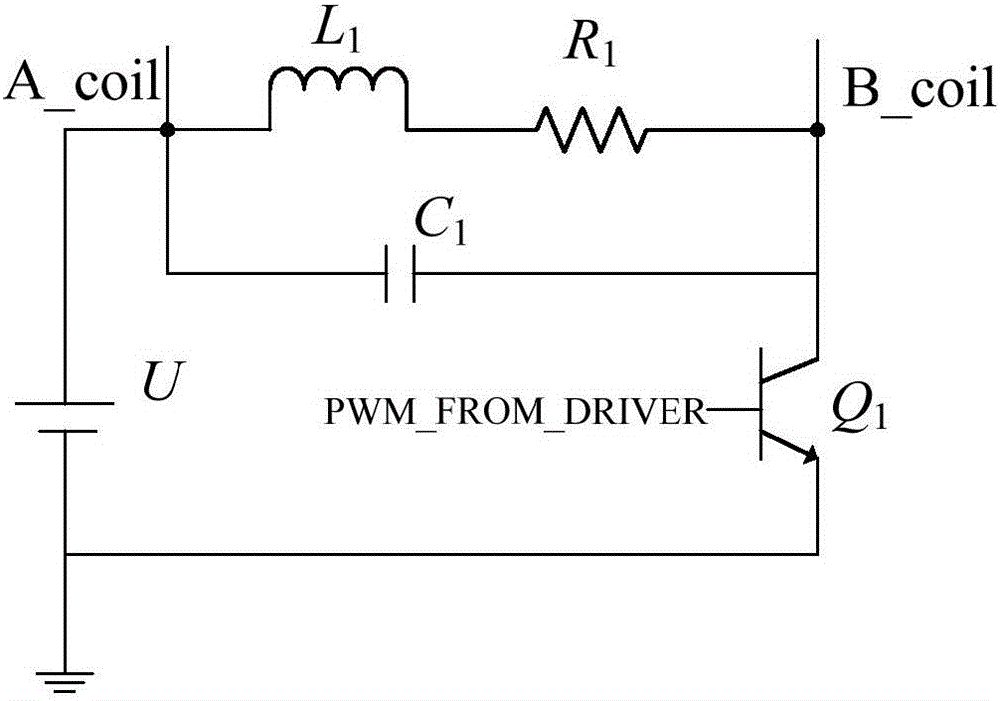

[0058] Step S110, analyzing the single-tube induction heating main circuit and the single-tube induction heating self-excited oscillation circuit, so that the single-tube induction heating self-excited oscillation circuit increases the delay time at the turn-on point;

[0059] Specifically, it can be seen from the above analysis that adding a fixed delay time can realize full-range load ZVS.

[0060] Step S120, when the delay time satisfies the first preset condition, according to the first preset condition and the turn-on condition of the insulated gate bipolar transistor IGBT, the delay time satisfies the second preset condition, wherein the first preset condition includes The first threshold time Δt and the second threshold time t m ;...

Embodiment 2

[0122] Figure 6 A schematic diagram of a system for realizing circuit ZVS based on delay time provided by Embodiment 2 of the present invention.

[0123] refer to Figure 6 , the system based on the delay time to realize circuit ZVS includes:

[0124] The delay time increaser 100 is used to analyze the single-tube induction heating main circuit and the single-tube induction heating self-excited oscillation circuit, so that the single-tube induction heating self-excited oscillation circuit increases a fixed delay time at the turn-on point;

[0125] The threshold time acquirer 200 is configured to make the delay time satisfy the second preset condition according to the first preset condition and the turn-on condition of the insulated gate bipolar transistor IGBT when the delay time satisfies the first preset condition, wherein the first A preset condition includes a first threshold time Δt and a second threshold time t m ;

[0126] Extremum value obtainer 300, for according...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com