Straw smashing and carbonizing vehicle special for field operation

A straw crushing and field operation technology, applied in carbonization furnaces, applications, agriculture, etc., can solve problems such as increased carbonization costs, low work efficiency, and inappropriateness, and achieve the effects of increasing crushing efficiency, reducing weight, and reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with accompanying drawing, the embodiment that the present invention creates is described in detail:

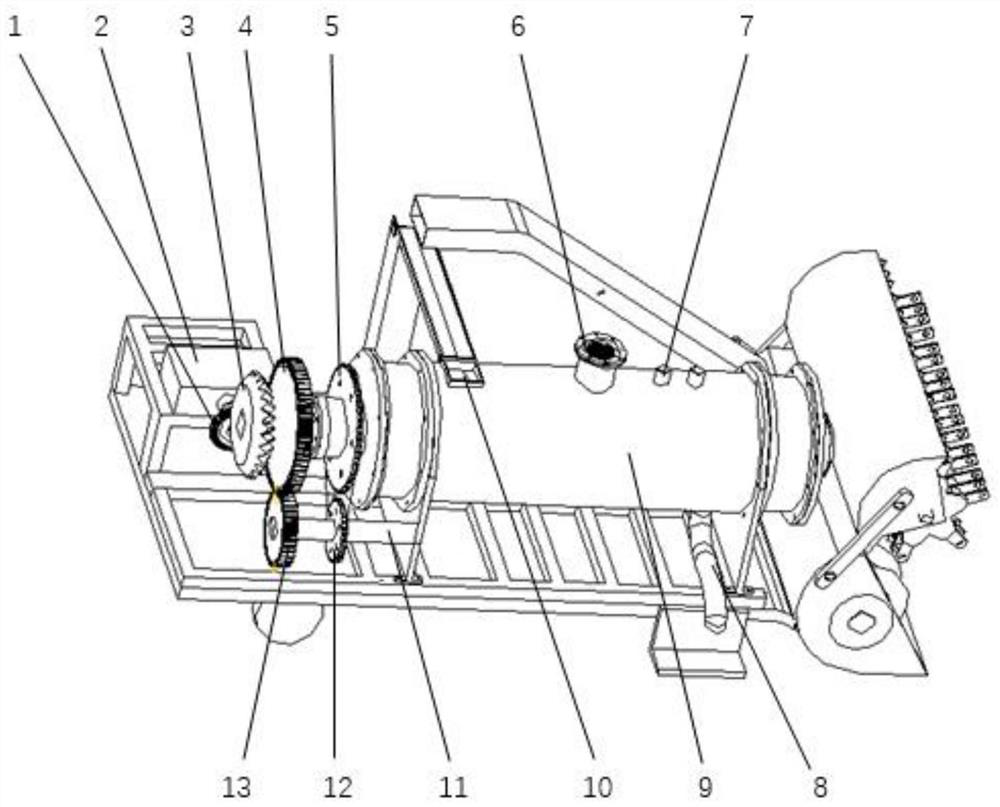

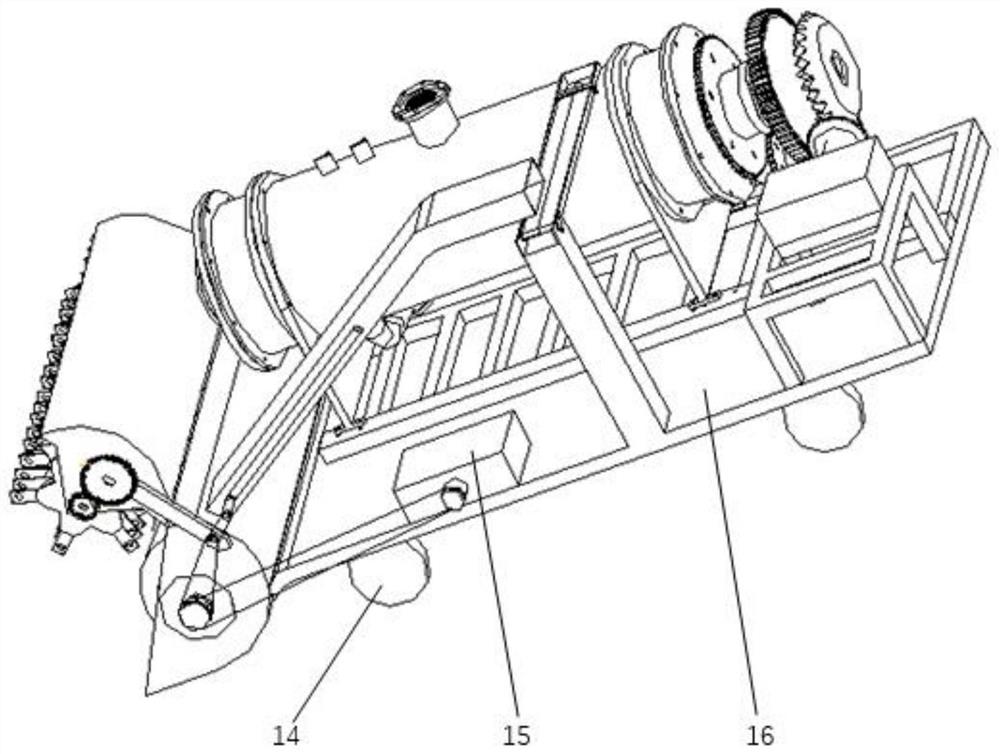

[0021] The special straw crushing and carbonization vehicle for field operation of the present invention comprises a vehicle body (16), four wheels (14) are arranged at the bottom of the vehicle body (16), and a straw crushing system and a straw continuous carbonization system are arranged on the vehicle body (16). and power transmission systems;

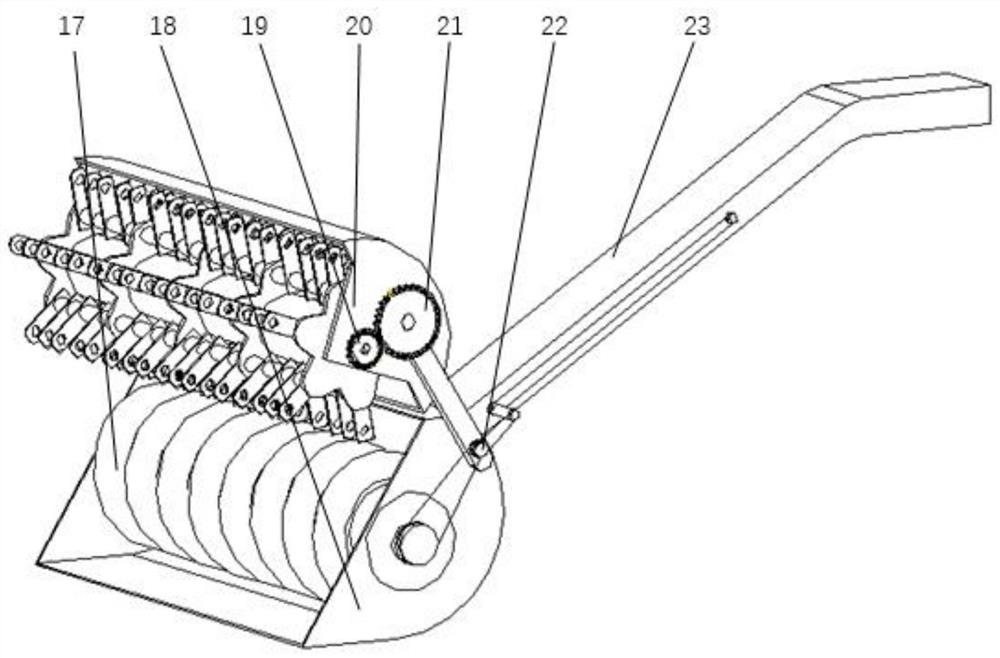

[0022] The straw crushing system includes a straw crushing cylinder (20), a screw conveying cylinder (18) and a straw conveying pipeline (23). Above the cylinder (18), the front sides of the straw crushing cylinder (20) and the screw conveying cylinder (18) are all open. The straw crushing cylinder (20) is equipped with a cutter crushing mechanism, and the screw conveying cylinder (18) is rotated and installed. There are shaftless spiral blades (17), and the rear end of the screw conveying cylinder (18)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com