Battery pack charge-discharge control circuit and electrocar power battery system

A charge and discharge control and control circuit technology, applied in battery circuit devices, electric vehicle charging technology, electric vehicles, etc., can solve the problem of short life of power batteries, and achieve the purpose of improving service life, reducing decay speed, and eliminating potential safety hazards. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

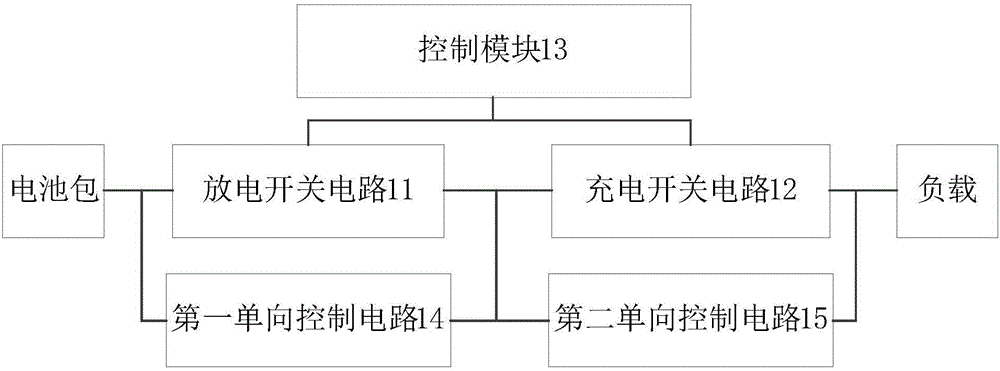

[0032] figure 2 The structural block diagram of the battery pack charge and discharge control circuit provided in the first embodiment of the present application. The battery pack charge and discharge control circuit provided in this embodiment is applied to the electric vehicle power battery system. A battery pack charge and discharge control circuit pair has multiple The charging and discharging of a battery pack in the power battery system with parallel battery packs is controlled, specifically, as figure 2 As shown, the battery pack charge and discharge control circuit includes a discharge switch circuit 11 , a charge switch circuit 12 , a control module 13 , a first one-way control circuit 14 and a second one-way control circuit 15 .

[0033]The discharge switch circuit 11 is used to turn on when the battery pack is discharged, and to turn off when the battery pack is charged; the charging switch circuit 12 is used to be turned on when the battery pack is charged, and t...

no. 2 example

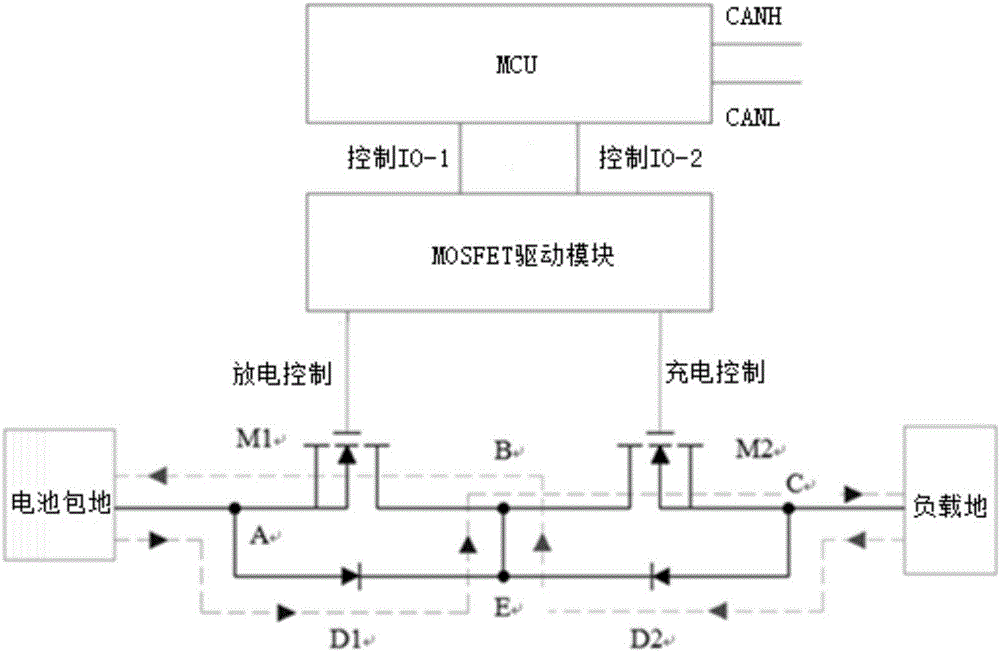

[0044] image 3 It is the circuit principle diagram of the battery pack charge and discharge control circuit provided in the second embodiment of the present application. The battery pack charge and discharge control circuit provided in this embodiment is applied to the electric vehicle power battery system. A battery pack charge and discharge control circuit pair has multiple Control the charge and discharge of one battery pack in the power battery system of four parallel battery packs, specifically, such as image 3 As shown, the battery pack charge and discharge control circuit includes an MCU, a MOSFET drive module, a first MOSFET tube M1, a second MOSFET tube M2, a first diode D1, and a second diode D2. It should be noted that this implementation The examples only illustrate the electronic components included in the circuit, and are not intended to limit the specific circuit composition of the battery pack charging and discharging control circuit of the present applicatio...

no. 3 example

[0054] Figure 4 The structural block diagram of the electric vehicle power battery system provided by the third embodiment of the present application includes a plurality of battery packs 20 , a plurality of control circuits 10 , a plurality of collectors 30 and a control unit 40 .

[0055] Wherein, multiple battery packs 20 are connected in parallel in the power battery system, and each battery pack includes multiple single batteries connected in series and / or in parallel. Each control circuit 10 is connected in series with a battery pack 20, and each control circuit 10 controls the charging and discharging state of the battery pack 20 connected in series with itself. The control circuit will not be described in detail here. Each collector 30 is connected to a battery pack 20 for collecting working parameters of a battery pack 20 , including parameters such as voltage, current and temperature of the battery pack 20 . The control unit 40, as the general control part of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com