Perovskite solar cell and preparation method for same

A solar cell and perovskite technology, applied in circuits, photovoltaic power generation, electrical components, etc., can solve problems such as incomplete matching of Fermi levels, photocurrent hysteresis, and use restrictions, and achieve optimized interface contact characteristics and easy operation , the effect of improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

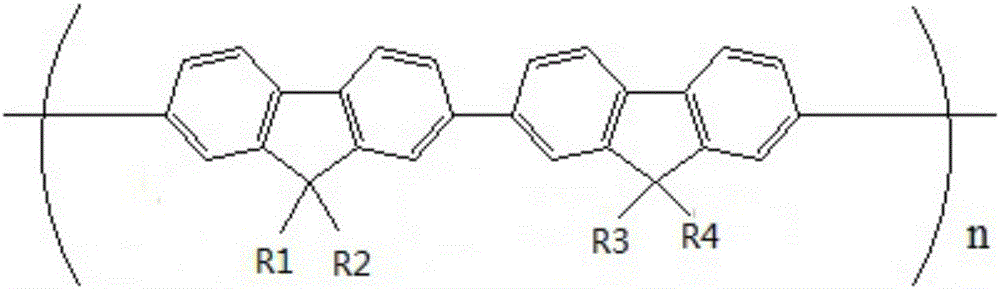

Embodiment 1

[0029] Such as figure 1 As shown, a perovskite solar cell is composed of a conductive substrate 1, a hole transport layer 2, a perovskite layer 3, an electron transport layer 4, a cathode modification layer 5, and a metal cathode 6 from bottom to top. Layer 5 uses amphiphilic fluorenyl polymers containing polar groups to replace the traditional inorganic compound cathode modification layer, and uses the interfacial dipole effect of polar group hydroxyl groups to reduce the potential between the metal cathode 6 and the electron transport layer 4. Barriers, reduce interfacial recombination, and improve the performance of perovskite batteries. The metal cathode 6 has a thickness of 80nm; the cathode modification layer 5 has a thickness of 5nm, the electron transport layer 4 has a thickness of 90nm, the perovskite layer 3 has a thickness of 350nm, and the hole transport layer 2 has a thickness of 15nm.

[0030] The conductive substrate 1 is ITO conductive glass.

[0031] The hol...

Embodiment 2

[0040] Such as figure 1 As shown, a perovskite solar cell is composed of a conductive substrate 1, a hole transport layer 2, a perovskite layer 3, an electron transport layer 4, a cathode modification layer 5, and a metal cathode 6 from bottom to top. Layer 5 uses amphiphilic fluorenyl polymers containing polar groups to replace the traditional inorganic compound cathode modification layer, and uses the interfacial dipole effect of polar group hydroxyl groups to reduce the potential between the metal cathode 6 and the electron transport layer 4. Barriers, reduce interfacial recombination, and improve the performance of perovskite batteries. The metal cathode 6 has a thickness of 50nm; the cathode modification layer 5 has a thickness of 10nm, the electron transport layer 4 has a thickness of 150nm, the perovskite layer 3 has a thickness of 500nm, and the hole transport layer 2 has a thickness of 30nm.

[0041] The conductive substrate 1 is FTO conductive glass.

[0042] The h...

Embodiment 3

[0050] like figure 1 As shown, a perovskite solar cell is composed of a conductive substrate 1, a hole transport layer 2, a perovskite layer 3, an electron transport layer 4, a cathode modification layer 5, and a metal cathode 6 from bottom to top. Layer 5 uses a copolymer of amphiphilic fluorenyl and phenyl containing polar groups to replace the traditional inorganic compound cathode modification layer, and uses the interfacial dipole effect of the polar group hydroxyl group to reduce the metal cathode 6 and the electron transport layer 4. The potential barrier between them can reduce the interfacial recombination effect and improve the performance of perovskite batteries. The metal cathode 6 has a thickness of 150nm; the cathode modification layer 5 has a thickness of 8nm, the electron transport layer 4 has a thickness of 50nm, the perovskite layer 3 has a thickness of 300nm, and the hole transport layer 2 has a thickness of 20nm.

[0051] The conductive substrate 1 is a fl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com